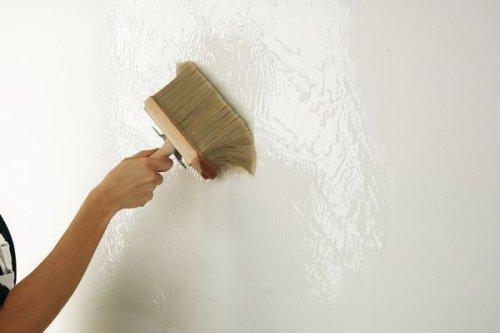

The primer of the walls is the most important component of the repair, since the quality of subsequent operations depends on this process. It significantly increases the adhesive properties of the surface, improving the adhesion of finishing materials and bases, and also prevents cracking, the appearance of divorces and stains. Wellproved walls are not afraid of moisture and continue to retain their appearance.

Content

Do you need to prick the walls?

Beginning builders are often faced with this question. After all, you can moisten the walls with water and perform the necessary work. In fact, everything is much more serious. To begin with, we suggest understanding and consider how the primer works.

To date, many emulsions for primer construction works are aqueous colloidal solution consisting of small polymer particles and special additives. When they are applied to the base, the composition is evenly distributed over all microcracks and large pores, then the small particles of the polymer are drunk between themselves, thereby forming a homogeneous solid film.

The latter becomes a barrier to penetrate moisture, but perfectly passes the air and steam. All this is necessary in order to:

- dedusted surface;

- make sticky base coating for best adhesion and tile adhesives, plasters, etc. a wall surface;

- extend the life of the fabric and appearance of the walls;

- neutralize cracks and separation;

- create an opportunity to apply to the dark surface of the lighter colors;

- reduce odor paints;

- enhance surface gloss;

- protect the surface from moisture, UV rays and corrosion;

- improve the adhesion surfaces;

- hide spots and discolored portions of the surface;

- prevent the occurrence of mildew and the like

The better primed wall

More recently, a primer produced a universal type and is used for all occasions. However, today DIY stores offer a wide range of compositions from different vendors and special purpose.

So modern primer differ in their composition and are:

- liquid;

- dry;

- mineral;

- acrylic;

- alkyd etc.

At the same time available and specific primers, which are intended for the treatment of concrete surfaces, namely metal, brick, concrete and wood.

Despite such a great variety in their properties and purpose primers are divided into two main groups:

1. Adhesive.

The main task of these compositions - is to improve the adhesion layers of finishing materials. Such a primer may be applied before painting the walls, applying tiles and gluing wallpaper.

2. Reinforcing (prime primer).

This type of solutions used to strengthen unconsolidated and porous surfaces, as well as to solidify, bonding the top layer and impart water resistance. Such reinforcing primer penetrates the dry surface treated 2-3 cm in depth, and deeper penetration of 10 cm or more.

Thus, absolutely every surface to be primed, as the only way to protect the color of the wooden walls and prevent it from rotting, and metal - to slow down corrosion and provide excellent grip.

How to choose a primer

By purchasing a primer should be based on the physical parameters and the state of the treated surface. Since the basic characteristics of the model:

- ability to absorb moisture;

- porosity;

- looseness.

It is these parameters that determine the reliability and strength of finishing building materials. For example, if the walls are fine-pour, sufficiently dense and poorly absorb moisture, then you need to pay attention to the adhesive compositions. If they are strongly porous, loose and not durable, then it is not necessary to do without strengthening deep penetration primers. For concrete surfaces, mineral solutions are perfect with the addition of cement.

Recommendations for the choice of primer:

- if the room has increased humidity, then the primer should be selected, which creates a reliable waterproofing layer. In this case, it must be applied in 2 layers;

- if you are going to progress the walls before painting, then select finishing buildings from one manufacturer. It also recommends creating an impregnation of the surface in 2 layers;

- carefully study the appointment, composition and labeling of the primer before buying;

- remember that the minimum consumption of the solution is possible when it is applied to a smooth, dense and non-porous surface and, on the contrary, the maximum - when impregnating loose, porous and dry bases.

Types of primers

1. Universal.

Such solutions can be grined by the walls before wallpaper or use in the complex repair of small areas.

2. Acrylic or emulsion.

They are universal, can be used to process almost any surfaces with the exception of metal. Such primers are considered environmentally friendly, dry for 2-3 hours, do not have an unpleasant odor.

3. Shellakovy.

This type of solution is ground the bumping boards on which the resin protrudes. In addition, they can be used as an insulator for water-soluble verses.

4. Alkyd.

Supervised wood, concrete and metal surfaces impregnate such compositions. In addition, they can be poured into different colors.

5. Polystyrene.

This type of primer can handle plastered and wooden planes. However, it is not recommended to be applied indoors.

6. Mineral.

Mineral primers are used to improve the properties of concrete walls indoors. In addition, they can be used to impregnate plaster and silicate brick.

7. Glifthawic.

Apply to the processing of metal surfaces.

8. Metal primers.

Such primers are able to protect the black metal from the occurrence of rust and corrosion, and color - from oxidation. At the same time, a certain variety of solution is used for each metal type.

9. Perchlorvinyl.

This type of primer can handle metal, brick and concrete surfaces, but it is better not to use it in the room.

In addition to the above primers, there are many other highly specialized compositions - polyvinyl acetate, phenolic, polystyrene, etc. They have a special purpose and are applied in professional construction.

When the walls are stigled

Protecting the walls follows after removing peeling pieces, applying putty and in front of the painting walls, or shook wallpaper.

How many times to prinurate the walls

- brick - at least 2 times, paying special attention to the seam;

- Fiberboard - from 2 times;

- concrete - from 2 times;

- tree - from 4 times;

- metal - from 2 times.

Grinding stone wall video: