The flooring device with parquet board has always been considered a status symbol and a good taste. Excellent appearance and decent operational characteristics of the parquet made it one of the most popular floors. However, during the mass construction and limited resources, a new type of coating was invented, which in terms of its characteristics did not step by parquet, but it cost cheaper.

Content

Laminated coating, or just a laminate, has a number of advantages compared to the parquet. It is much cheaper, does not require constant care, more moisture resistant. Like most artificial materials, manufacturers offer the consumer a wide range of colors and laminate textures that will help embody any designer fantasies. How to properly put laminate with your own hands on a wooden coating - further in the article.

What is laminate and how to choose it correctly

Laminate is a peculiar puff pastry from several materials that give it the necessary properties. A laminated coating is produced in the form of boards, in the ends of which locks are installed. Thanks to the locks, they are connected. The whole boards of laminate consists of 5 layers:

- The lowest layer is melamine. His task to protect the board from the penetration of moisture from the floor substrate to the inner layers.

- Next goes a layer of fiberboard and chipboard, which is the basis of the laminate.

- A layer of impregnated paper resin is laid on top of the base, which is also designed to protect the basis from moisture.

- Next goes a layer of paper with a pattern applied to it. Usually the drawing is made under the noble wood or stone.

- A protective film is applied on top of the drawing, which protects the laminate not only from dirt and moisture, but also from mechanical damage.

The minimum chalk thickness is 8 mm. This parameter must be selected individually. If the coating is high pressure, then the thickness of the board must be greater. It is also worth considering the room heating system. So, for warm floors, it is better to pick up a thin laminate so that it provides better thermal conductivity. And, on the contrary, if heating radiators are used, it is better to take the laminate to reduce heat loss through the floor.

When choosing a laminated coating, you must pay attention to his class. This indicator displays the resistance of the coating to abrasion. The higher the class - the higher the resistance. Classes range from 21 to 33. The first is suitable for residential premises with low permeability, the second - for public places with a high degree of load. Naturally, the cost of the latter will be much higher, however, do not save on quality and buy even for home 31 or 33 class. In this case, it will last for quite a long time.

If there are children in the house, it is better to give preference to a laminate with the removed chamfer. The boards of this material during the compound do not form a solid coating, and leave a small decorative clearance among them. Thanks to him, when hugging and moisture, and children often pour various drinks to the surface, the lock when swelling takes place for expansion and does not swell.

Personal attention should be given to choosing locks. They are two species:

- Glue. Used extremely rarely. Finding a laminate with adhesive lock is very difficult, and you can not find the glue for its laying.

- Mechanical. Represent a simple latch. They are also called QuickStep. To lay such a material even independently does not make much difficulty. There are two types of mechanical locks:

- Click - locks. Located at an angle of 45 ° to the board. Laminate with such locks is distinguished by its undemanding to flattering gender. The coating height difference may be up to 3 mm on the temporal meter. Independent laying of such a laminate is not special difficulties;

- Lock - locks. Jobs are connected, which eliminates the presence of irregularities on the floor before laying, it must be perfect. The cost of such a laminate is lower, but there are much more problems with its installation.

When choosing a laminate should not save. Qualitative material is a pledge of a large service life of the floor covering.

Preparation of wooden floor before putting laminate with your own hands

If we put the laminate with your hands on the concrete floor is not problematic, then there are some difficulties with wooden. So, it is necessary to spend thorough preparation before starting work:

- First of all, you need to assess the condition of the flooring. Wooden board boards should not have traces of rot, visible damage. Paul should be smooth. Otherwise, it is impossible to drain the laminate on it.

- If the floorboards are too old or drunk, it is better to replace such a surface. The boards are dismantled, and the sheet material is stacked instead. As a rule, a thick fane or OSB is used as it. The latter is a plate of large chips glued with a special resin. OSB - Pretty durable material, no moisture is afraid, even for a long time. Its only its disadvantage is a sharp smell that weathered over time. Plywood is also great for the floor, however, it costs it more expensive. The thickness of the plate should be at least 22-25 mm to ensure the strength of the floor.

- Before laying material, it is necessary to conduct an audit and alignment of the lag.

- If the floorboards are in a normal state, you should not remove them. In this case, it is advisable to spend their cyclical, remove the layer of paint and impregnate with oil.

- If, after the work performed, it was not possible to achieve frequency of the floor, then on its surface you can lay the Faneur or the same OSB only with a thickness of 5-7 mm. There will be no load on it, but the more smooth surface of the floor is given to the coating.

- It is necessary to remember another important point. If the laminate is laid on the sheet material OSB or Paneur, when they are laying between sheets, it is necessary to leave a small gap. Then, even when driving, they will not make an unpleasant creak.

- In order for the base before laying a laminate, it is resistant to carry out its completion. In places where creak heard when walking, you need to strengthen it and immobilize.

How to put a laminate on the wooden floor do it yourself

Tools and materials

For a few days, before putting laminate with hands on the wooden floor, it is getting out of the packaging and put in the room. This is done in order to start the temperature and humidity of this room before starting work.

To lay a laminate on the wooden floor, you will need:

- Electrolovka.

- Cornel, pencil, ruler.

- Screwdriver.

- Hammer.

- Polyethylene film. Its appointment is to take care of the laminate from the penetration of moisture, which can accumulate under its surface. The board itself, as has already been said earlier, has a reliable layer of protection in the form of melamine, but the moisture castles will affect quite detrimental. Some masters advise before stacking to process the castles of Olife, however, as far as an effective step is not known.

- Substrate. In order to put a laminate or parquet with your own hands, apply a substrate of two types: synthetic (polyethylene or polyurethane foam) and genuine (cork). The latter is more expensive, however, has better performance and more environmentally friendly. Bitumen fiber substrates are also found with plugging of cork grains. The main appointment of the substrate is compensation of residual unevenness of the base of the floor, ensuring noise insulation and reduction in heat loss. The lining material is produced in rolls or square mats.

Order work on laying laminate on the wooden floor with your own hands

If you are wondering how to put a laminate with your own hands, then consider a detailed order of work:

- Before starting work on the installation of the substrate, it is necessary to clean the floor from the dust particles, construction trash. It is advisable to free the room from furniture. First, it will not interfere with work, and secondly, it will not shift the basis for its weight, which will help morely put the laminate.

- The first thing is placed polyethylene film. This mustache is made approximately 15-20 mm, after which the seam is bonded by scotch. So that the film does not move, in the corners of the room you can attach nails.

- The next step is stacked the substrate. Unlike the film, the substrate lays the jack, which is still fastened with tape. Any of the types of substrate perfectly cuts the wallpaper knife.

- Now the laminate laying time has come. Start you need from a long corner of the room. The first board always stacked entirely.

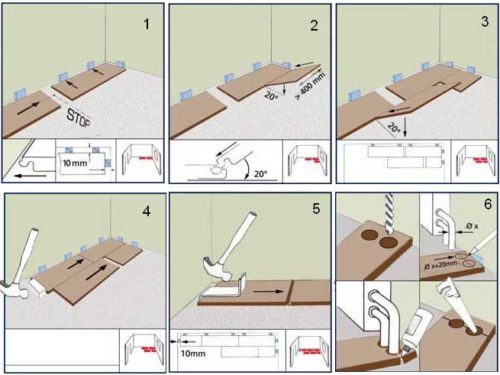

- When working with laminate, it is necessary to always leave the technical gap of 10-12 mm from the wall. This is done so that he does not drink moisture from her. In order to observe a uniform clearance, you can cut a rack with a thickness of 10 mm into small pieces and lay along the wall. They will play the role of buffer.

- When connecting boards to the lock, you must control the correct position. The laminate is connected very simply - the board rises up, its grooves will start in the castle, and it goes down. Then the plank boils with a hammer to remove the gap. To beat the hammer at the end of the board is strictly forbidden, for this you need to use a wooden extension.

- When the distance is less than the length of the row, the length of the board will be needed to do. The board is applied to the latter, the place of the cut is noted. Then the coal is strictly perpendicular to the cut line. Laminate Lobzik with small teeth. This is done in order to do not break the edge during the cut, which can spoil the board.

- Important Tip: When buying a laminate, it is necessary to make a stock of 10% of the required area in case of damage to the material. If you buy a laminate, you can not guess with a tint, because in different parts of the same color, the shade can be different.

- The second row is stacked with overlapping. This means that the seam between the boards of the second row should fall on the middle of the board first.

- After the laminate is laid, set the decorative plinth.

How to put a laminate on Faneru do it yourself: photo