No construction is done without concrete. If you need a small amount, it is not difficult to prepare it manually, clearly following the instructions. But to obtain a solution of good quality greater volume, the use of special equipment is invariably required. A large influence on the strength of the future structure in this case has the correctness of the selection of the mixing device.

Content

- How to choose a concrete mixer for giving?

- Basic principles of selection of concrete mixers

- Mechanism device

- The principle of mechanical action

- Power concrete mixers

- The voltage required for the stable operation of the device and the principle of fuel consumption

- Baraban dimensions

- Time of continuous work

- Additional functions

- Class of concrete mixers

- Manufacturers and models of concrete mixers

- Video

- Conclusion

How to choose a concrete mixer for giving?

To correctly select the unit, read the following indicators in advance:

- The volume of the required mixture

- Time allotted for all work

- Affordable voltage of electrical stroke

- Work season

- The number of workers for the preparation of the solution.

Basic principles of selection of concrete mixers

Specifying the question "How to choose a concrete mixer for home", determine the parameters of the criteria. We highlight important conditions that affect the volume, the speed of preparation of the mixture, the quality of the finished solution, the usability:

- Mechanism device

- The principle of mechanical action

- Power

- Voltage required for stable operation of the apparatus or fuel consumption principle

- Baraban dimensions

- Time of continuous work

- Additional features facilitating production process

- Manufacturer and model.

Mechanism device

Distinguish the following types of concrete mixers:

- crown

- gear.

Important! It is difficult to give certain recommendations in this regard. Make a choice yourself, given the personal preferences, more important characteristics and your professional skills.

Crown

- The principle of operation is a gear on the drum (crown) attached to the engine. Rotational motion ensure the teeth moving in a circle.

- Belt transmission protects the engine from breakdown when overloading or jamming.

- The most frequent cause of breakage is the abrasability or rupture of the belt, which can be replaced quite quickly. A gentle-rings can also break out due to the falling garbage from the teeth, especially if it is made of durable material.

Important! If in the process of solving the issue, what a concrete mixer is better, you have given your preference to the weathered model, pay attention to the metal (cast iron or steel) design element - it will last longer than polyurethane or plastic.

- Consumes a lot of electricity in the process of work.

- Low price.

Important! This type is recommended for use without professional skills.

Reducer

- Have less transfer links in the system.

- The mounting of the drum and rotation occurs by the shaft on the gearbox.

- There are rare cases of breakage, given the design features, but if the breakdown occurred, the repair of this type of concrete mixer is not subject to repair.

- Little energy consumption than pesting structures.

- Small noise when working.

- High price.

Confatisfying

In addition to the above types of design, a separate group will highlight automotive concrete mixing plants. The fixed devices on the cargo machine make it easy to move to any point of the construction site without spending time and deterioration of the solution of the solution. The use of such models is more used for industrial purposes of large construction.

The principle of mechanical action

This criterion is an indicator of the technology of mixing solution.

Distinguish two types:

- gravitational

- forced.

Gravitational concrete mixers

The principle of operation of the device is the rotation of the drum. The blades are fixed in this process. Features of the machine device provide thorough mixing and exclude sliding, wiggle through the walls of the mixture. Such devices are suitable as for the manufacture of a rigid mixture, as well as easier, watery.

An excellent option will be to solve the problem "How to choose a concrete mixer for giving" to perform a small volume work, for the arrangement of the tracks of a green zone, paving paving slabs, overhaul of the building.

Forced mixing devices

In the aggregates of this type, the drum is still, and mixing occurs by rotating the blades. More suitable for the preparation of plastic, viscous, liquid solutions, but not recommended for the preparation of concrete with the content of large elements. The concrete mixer itself has large sizes. The rational will be the acquisition of a compulsory apparatus with a large-scale project of building building.

Power concrete mixers

Engine power affects the quality of mixing the solution and the permissible duration of work. This indicator varies from 150 W to 2-3 kW. Make a choice based on the planned production volumes.

How to choose a household concrete mixer?

For non-professional use in private construction, a suitable figure of 550-700 W, which will ensure uninterrupted operation in good quality of the solution. It will not happen to operate power supply. For a long continuous process, pay attention to the concrete mixers with a capacity of 1000 W.

The voltage required for the stable operation of the device and the principle of fuel consumption

The solution to the issue "How to choose the right concrete mixer" is necessarily associated with an affordable voltage of the power grid. Note that the model you determined as the most appropriate corresponding to this indicator. Otherwise - you will have to install a diesel generator for production of 380V, which will entail additional costs.

Important! Diesel devices are mainly calculated on large volumes of production or are part of automotive installations.

Baraban dimensions

Volume of tank

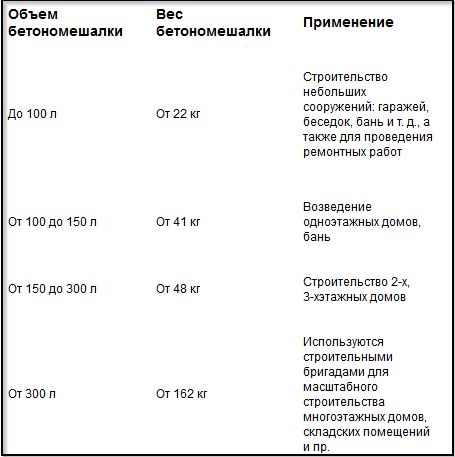

The parameter range of the drum is very wide - from 50 to 1200l. Make a choice yourself, given the volume of upcoming work.

Universal recommended size for small construction - 130-150l.

Important! Please note that the set parameters of the drum and the output of the finished solution differ. The amount of the mixture decreases on average by 1/3. Also when forming a bookmark, keep in mind that part of the composition settles on the walls.

Wall thickness

In addition to the volume, the thickness of the walls of the reservoir is taken into account. Concrete mixers of an attractive glossy appearance without seams are most often made of steel, the thickness of which is not more than 2 mm. If it is unclear, it will be quite enough.

For regular work, at least, the average volume of the manufactured solution, pay attention to the equipment, the tanks of which have welded seams. This will provide a longer service life and eliminate the deformation during cleaning after the completion of all works. The thickness of the walls of such a drum varies within 3-4 mm.

Browse the applied table below the most suitable size in accordance with the type of work.

Time of continuous work

For this principle, two groups are distinguished:

- continuous action

- periodic functionality.

How to choose a concrete mixer for this criterion? - easy enough.

Continuous actuators are complex and designed to produce a mixture in large volumes for a long time. Therefore, for domestic use within private construction, especially without special skills, take the unit with periodic functioning.

Important! Following this advice, you can at any time need to take a break in the working process, not allowing premature drying of the solution. Such an approach will exclude a significant overrun of materials, and, accordingly, the acquisition of periodic concrete mixer is more profitable.

Additional functions

In this category, we will draw the characteristics of concrete mixers, which are more affected by the convenience of the process of preparing the solution throughout the entire period of operation:

- Principle of loading materials and unloading of the finished solution (manual, automatic)

- Convenience of tank tank with handheld technology, presence of pear position locks

- Seasonality of the operation of the apparatus outdoors

- Compactness, the possibility of moving without the use of special equipment

- Dust Emission Limits

- Noise absorbing device

- Color of external and internal design

- Manufacturer's warranty

- The presence of service centers in the city (country).

Class of concrete mixers

According to this principle, we allocate two categories:

- professional equipment

- household aggregates.

Features of professional concrete mixers:

- designed for large volumes of production

- sophisticated use

- preferably assume the use of high voltage or fuel.

Distinctive features of domestic equipment:

- compact sizes

- a light weight

- easy to manage

- little performance

- the work provides the presence of 220V in the network located near the preparation location.

Manufacturers and models of concrete mixers

The natural question that occurs during the selection of equipment: "How to choose a concrete mixer, what manufacturer is better?" The answer to it for each individual buyer will be different, but general recommendations on the choice must be discussed.

Concrete mixers of the following companies are in the greatest demand on our market.

Guy Noel (France)

Specifications:

- Cog ring from plastic

- Availability of special protective casing

Important! Consider, during operation, this casing sometimes causes inconvenience due to the mixture on it.

- Problematically find service in Russia

- Low drum location that is not always convenient

- Electronic control unit, parts of which more often than other components fail.

Altrad Spomasz JSC (Poland)

Distinctive nuances:

- excellent quality

- Long experience of engineers (over 50 years)

- Developed network for all European countries, including in our country

- Wide line of models with variable utility

- Designed for various operating conditions (heat, frost, any precipitation, no power grid, special trailer for transportation)

- High-quality waterproofing of an electrical device

- Temperature sensors preventing overheating

- Crown - high-strength cast iron treated with ion-plasma nitriding

- The color is taken by the powder method, which significantly prolongs the service life and keeps an attractive appearance for a long time, excluding chips and paint erasing

- Noise level does not exceed the norm within 76 dB.

Limex (Croatia)

Models LS 125, 165, 190 (digital value indicates the parameters of the concrete mixer pear).

Peculiarities:

- Toggleless transmission without additional protection from steel with high strength indicators

- Additional ribs rigs increase the reliability of the entire installation

- Good wear resistance

- Low noise when working any apparatus

- Powder method of staining of all parts.

Bart Import Poland (Poland)

The company supplies POWER TEC L120-460 concrete mixers market (variationsight of the mixing of the mixing reservoir).

Options:

- Small drum size compared to similar concrete mixers of other manufacturers

- Protective crown cover, which warns his damage

- Strengthened chassis

- Protected Engine

- Heavy

- Material for the production of drum - galvanized steel

- The tilt is performed using a specially installed wheel with fixation fastener

- Not so attractive externally, all developments relate mainly to the technical part.

Tsunami (China, Assembly Russia)

The RM125, 140, 160, 180 model range (the nominal indicator corresponds to the volume of pears).

- Economical option for domestic purposes

- Good price-quality ratio

- Wide Service Network

- Cast iron crown, more durable to use

- Power 550-800 W

- Lightweight structures, making it easy to move around the construction site as needed

- Ease of assembly and disassembly plant available even to those who do not have professional skills in this field.

HERZ (Germany)

The company is represented on the market model DM 360 and 560 (the numerical value determines the volume of the reservoir).

- The most expensive equipment professional class

- High build quality

- diesel power

- The design is designed to meet the possibility of using and moving even in hard-to-reach places with an unprepared roadway

- Gravitational mixing system

- Equipped with a special steering wheel for the convenience of unloading the solution

- Designed for the preparation of large volumes of the mixture.

Video

Check below the applied video recommendation for the choice of concrete mixer.

Conclusion

Be proceed to the choice of concrete mixers only after they have studied all the subtleties of choosing this type of equipment. Thus, you will protect yourself from the acquisition of the apparatus of poor-quality production. The subsequent execution of work with a concrete mixer selected in accurately compliance with all preferred criteria will provide a productive process of preparation in the time limit, which is the main purpose of acquiring this equipment.