It is no secret that the strength and durability of the construction depends on the reliability of the foundation on which it was erected. Without knowledge about the peculiarities of each type of basis, it is difficult to choose the most suitable base for the future building. Next, consider this issue more.

Content

General types of bases

If you want to build a private house, then for this purpose, one of the following types of bases usually choose:

- tape

- slab

- columnar,

- pile.

Each of the listed options should be considered more.

Ribbon foundations received their name due to their shape in the form of a tape. And to pour it at the site of construction is completely optional, because There is an embodiment of this type of basis from reinforced concrete blocks. Ribbon foundations are valued for increased strength, as well as for the ability to give them almost any form. More complex installation options are the base of the team type.

Distinguish the following types of belt bases:

- hard

- flexible

- monolithic

- intermittent.

Platy base options are a multilayer pie. Each of the components of its layers performs various functions - a protective, leveling, strengthening. The protective layer consists of a heater and material for vapor and waterproofing. As part of the leveling there are crushed stone and sand. The design of the foundation is strengthened using reinforcement rods, which are immersed in concrete.

Bound bases are elevated from finished blocks. This type of basis is quite reliable and is suitable for almost any types of buildings.

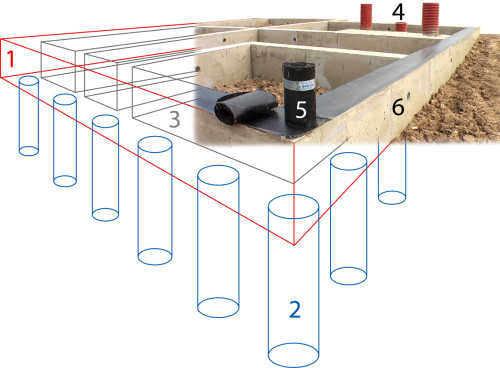

As for the pile bases, they consist of vertical piles, the upper part of which is aligned at one level and fastened as painting. There are several types of pile foundations. If the supports are installed for several pieces in different parts, then this is a bush pile basis. In the solid types of base, the support is very close to each other. When using a single type of pile foundation, the supports are placed in the corners. If the supports are screwed into the ground, they are already talking about the screw form of the foundation, and if they are clogged into the ground, then about the clogging type. If the supports are poured into the wells, then such a basis is called printed.

Next, we will tell you more about the pile and ribbon base.

Characteristics of Sailo Belt Foundament

This type of base is like a standard tape. The differences are the easier installation and preparation. In addition, it does not require the involvement of special construction equipment. Therefore, it can be done quite easily with scratch. The most important thing is to comply with all the necessary stages. Then on this foundation the installed building will be able to simultane enough time. But not always this method is suitable. In particular, it should be borne in mind that the design of this base provides for the shower in the soil. Therefore, a similar type of foundation is suitable if the weight of the house is quite large, and the walls of the structure will be made of stone and bricks. In addition, this basis is suitable in construction on movable bunched soils. If under the site where the house is built, there are groundwater and soil humidity increased, the device of the pile and ribbon foundation will be very relevant. The same applies to the case when the embossed area has a bias. In-depth piles of the foundation will not be collapsed by building under any climatic conditions.

It is important to know the advantages and disadvantages of different types of foundations. The following are the following:

- Ability to use on a plot with a strong bias.

- In addition, it does not need a lot of building material for its construction.

- It is also important that this type of foundation can be energized even on a weak soil. At the same time, the base is distinguished by resistance to soil shifts and considerable loads.

- For many, the decisive factor when choosing exactly this foundation can be a low cost.

This type of basis can be erected with your own hands. But at the same time, it is necessary to carry out difficult settlements for its arrangement, which forces only by specialists. This is one of the disadvantages of this type of foundation. In addition, on this basis it is not recommended to build heavy walls. In addition, it is problematic to equip under the building built on such a base, a basement or ground floor. Next, consider in more detail how to make a pile-ribbon foundation.

Pile and ribbon foundation do it yourself

Preparatory work

Before conducting work on the foundation tab, it is worth learn more about the soil on which the construction will be built. In particular, it will take information about the depth of its freezing at the selected area. This data will help to properly plan the depth of the foundation and marking of the territory.

This type of basis, as mentioned above, can be erected by almost any soil. Nevertheless, it is necessary to correctly calculate the depth of piles. So, they must be shrouded below the depth of the ground freezing about 0.5 meters. Only after that you can make the calculation of the amount of piles, as well as determine the width and length of the tape. To do this, the site must be cleaned and how to align. After which the markup is made. Next to the ground is driven by reinforcement or stakes from a tree.

The width of the frame is selected depending on the material from which the construction is performed. So, if the main material is wood, then for retention and uniform distribution, a wide 300 mm width. The construction with the walls from the foam block is erected similarly. If the construction material is a brick or a stone, then the width of the frame should be 400-600 mm. The depth of the monolithic top design should be at least 400 mm. The value of these parameters depends on the type of soil and weight of the building.

When the markup is done, then you need to determine the placement of piles. To do this, first outlines areas in the corners of the tape, and then the markup is performed so that there is a step of about 1.5 meters between the rest. In the diameter, the supports must be less than the tape. After that, you can begin to dig a trench in the depth of the ribbon, as well as to be drilled for the wellhead piles of a suitable size.

Stay's arrangement

In order to do well, you will need a special tool. Usually, for this purpose is used garden or manual borrow. Piles can be done or purchased in the finished form. In the latter case, the launch of the foundation is most likely it will cost more. When digging the well, consider that the depth should allow placing there not only the swarm of the pile, but also a sand pillow. Therefore, the dimensions of the wells must be 30 cm more than the length of the swollen part of the piles. If you need to score the supports of a special form to the desired depth, then the special equipment will be needed. In particular, to fulfill such work, you need a borough.

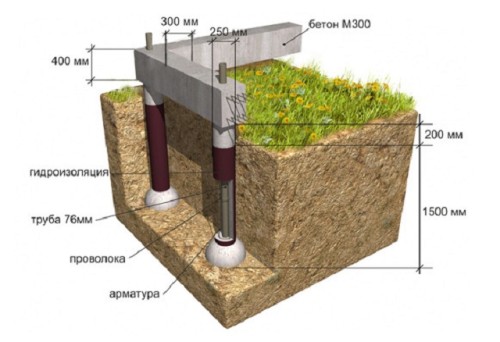

When the wells are ready, then the bottom of each of them is poured a sand pillow with a thickness of about 200 mm, which should be abundantly pouring water and tamper. After that, it is possible to install a pipe from a metal or asbestos cement. In addition, the walls must be displayed runnerdo. It is important to make a sole. To do this, the concrete solution is poured into the pile and lifted by about 300 mm so that the expansion in the form of the sole is formed below. With this sole, the pile is fixed. When the wells are ready, they make a sandy pillow in them. In addition, it is provided with a stronger compression of piles with soil. After that, the supports are aligned in a vertical position. It is necessary to have time until the concrete froze. While the sole will be stuck and strengthened, you can proceed to the device of the ribbon plate.

Ceiling Base Base Building Technology

The order of work at this stage is the following:

- When concrete freezes, the frame is inserted into the pipe, made of durable reinforcement. The height of the structure should be such that it takes to the top of the base tape.

- After the supports are ready, you need to make a wooden formwork. For its assembly, nails or self-tapping screws are used, and at the corners for greater strength, bars are attached. Any protruding structures should be only on the outside of the formwork. Walls are strengthened with screeds and pins.

- Inside the formwork lay the reinforcement in the form of a rod, the diameter of which depends on the calculated load. The rods are stacked in all three directions so that the three-dimensional mesh is obtained. Together they are associated with wire. The valves of piles and the tape of the base must be necessarily related, because This ensures the strength of the structure.

- Concrete first need to pour piles, but only after that the whole tape. From the design, air bubbles must be removed. This is usually done using a deep vibrator. The foundation mirror must be aligned, smooth off the rule and protect against atmospheric precipitates to the plastic film or any other material.

- During drying, you need to check the moisture content of the base in order to prevent drying. For this purpose, during the heat, the drying foundation should be slightly moistened, because Due to the rapid evaporation of moisture, cracks may appear.

- When concrete freezes and gains the desired strength, waterproofing and insulation can be engaged. This is because it is necessary that the wet concrete at low temperatures is inclined to cracking, and this eventually leads to the destruction of the base. For this reason, it is necessary after the construction of the foundation, it is necessary to do everything to prevent the impact of moisture.

Important moments

Once again it should be noted that in front of the foundation device it is necessary to clean the surface from the garbage, align it and make marking. At a prepared area, a trench of a depth of about half meter is digging under the foundation. After that, on the bottom for removal of water from the basis, sand or gravel is stacked. In addition, such a pillow reduces the pione of the soil. The wells are made in a certain order - first at the corners of the future building, and then around the perimeter so that between them there is a roughly equal distance of 2 meters. When digging a well necessarily takes into account the depth of the soil freezing.

Plates of polystyrene material are attached to special glue, and after drying it is additionally fixed by means of a dowel. As for the polyurethane foam, it represents a sprayed coating, which according to its principle of action is similar to the installation foam.