By making the decision to use the tile as a facing material, the first question that occurs, in addition to the selection of the shape and the shade of all fragments to embody its idea of \u200b\u200bthe pattern, is the purchase of high-quality glue. It is from how much it will correspond to the conditions of operation of the surface, the beauty and duration of the integrity of the decorated coating depends.

Content

In the process of choice, be sure to pay attention to a number of the following criteria, correctly selecting the complex. All the necessary parameters are indicated by the manufacturer on a pack with composition, so it is enough to read them carefully.

Criteria for technical parameters

We note those technical characteristics of tile glue that affect the quality of the cladding being created:

- Adhesion properties. This quality affects the reliability of the attachment. That is, the higher the specified indicator, the more durable adhesion is formed when the tile is in contact with the surface prepared for the trim, which ensures long-term operation.

- Plastic. This property affects the solidification speed and ease of uniform coating. When facing vertical surfaces give preference to the less ductile solutions to accelerate the curing process and prevent slipping tiles. When working with horizontal planes more convenient to use formulations very flexible. Their use allows you to create a perfectly flat surface with a small adhesive consumption.

- Permitted use. Be sure to consider their skills to implement the tiling when choosing a solution. Period of use may vary from 10 minutes to 45. Please note that after this period, the adhesive can not be restored. If you wait too long to paste all the fragments of tiles, it is necessary to prepare a new batch.

- Operating temperature tiling. Manufacturers indicate on the packaging of the allowable operating temperature range during installation. Following this requirement will ensure the proper level of the adhesive properties of a solution for bonding the tiles and the surface being treated.

- tile adhesive consumption. To perform a correct calculation of the required amount of solution is sufficient to know only the surface area under the lining and read the manufacturer's recommendations on the thickness of the layer for fixing the tiles.

Important! It is not necessary to exceed these parameters, as it not only does not increase the adhesive strength, but more likely to lead to premature failure. In addition, significantly reduced aesthetic appeal decorated surface after completion of all finishing work.

- complete solidification time. This figure should be considered in cases where tiling is only an intermediate step in the whole process of repair. Before proceeding to continue painting and decorating or installing furniture should be sure to wait for a specified time.

- The date of packing. Check that the glue has not expired, or - unlikely to be able to perform all the work because of the poor adhesion or the tiles will disappear very quickly due to a lack of reliable fastening. Stale adhesive composition in dry form is often hardens, because of which require more effort to prepare a solution, and the result obtained will not correspond to the number expected.

Important! Pay attention to the conditions for storage of glue (especially in the form of a dry mix). In violation of the transportation and storage of the packages, the indicators specified on the container will not correspond to reality - all characteristics will significantly decrease.

Classification by appointment

Depending on the size and type of tile, the venue of all facing works and the conditions of future operation, the types of solutions differ. For each specific case, select the appropriate type of glue with the enhanced characteristics of the desired direction.

According to this principle, the following categories are allocated:

- Adhesive universal. Used for standard low-dimensional tiles - 10 * 10 cm, 20 * 20 cm, 20 * 30 cm. Suitable only for wall cladding. The simplest composition with the corresponding inexpensive price. The ideal solution for the embodiment of uncomplicated finishes indoors.

- Reinforced solutions for medium-sized tiles. Such formulations are used both for laying outdoor and wall tiles. According to the type of material, not only for ceramic products, but also cladding from porcelain stoneware. If necessary, use for external work. The distinctive characteristic is the stability of the adhesive solution in the frozen state to the loads of different nature (static and dynamic).

- Glue for floor. In this group, solutions are isolated, when used by the destruction of the surface and its deformation at regular pressure load, for example, when installing heavy furniture at home or in public places with a large crossway. In addition to this type, the market is also presented with a line of adhesive compositions for floor alignment.

- Solutions intended for fixing powerful material fragments. The need to use adhesives of this type occurs when the surfaces of heavy tiles of large sizes or natural stone occurs. Features of the composition provide reliable fastening of large elements even on vertical surfaces. One of the most popular methods of application is a natural stone concrete finish.

- Glue for the bathroom. This type of solution is characterized by elevated waterproofing properties, preventing moisture penetration to the base of the surface on which the tile is fixed. Due to this, it does not cover the glue and the tile disappearance. Additional advantage - an obstacle to the appearance of mold and fungi in conditions of constant high humidity. In addition to facing the bathroom, suitable for trim and pools.

- Glue for outdoor work. It is highlighted in a separate category due to the features of operation. At the heart of such compositions there are additional plasticizers that increase the frost resistance of glue. Depending on the quality of the solution, the number of permissible cycles of frost-thawing varies. In addition to low-temperature resistance, the adhesives of this group are distinguished by both elevated adhesion properties, which makes it possible to fasten the elements of the tile of different formats.

- Solutions for finishing complex surfaces. This group includes perfectly smooth, slippery surfaces, such as glass or based on the old tile. In addition, there is a line of special solutions for cladding wood and drywall structures.

- Glue for decorative trim. It is used mainly for laying mosaic or transparent tiles. Such solutions have a white shade or colorless, which eliminates the decrease in the attractiveness of the decorated surface.

- Solution for facing furnaces and fireplaces. All compositions of this category are distinguished by the reinforced confrontation of destruction at high temperatures, up to 1000c.

Important! Be sure to adhere to the recommended application conditions in order to facilitate the entire process of laying the tile and prevent the rapid destruction of the decorated decorative coating.

What are the types of compositions?

To select the most user-friendly type of glue, familiarize yourself with the possible types of compositions presented in the list below:

- Dry mixtures based on cement. The most popular and in principle the only way to fasten the tile until recently. The current compositions of this type are significantly improved. With the fact that the basis is also exclusively natural ingredients, special additives-plasticizers increase certain properties.

Among the advantages of the use of dry mixtures, the following nuances can be noted:

Among the advantages of the use of dry mixtures, the following nuances can be noted:

- Water dispersion solutions. One-component formulations that are beneficial to the maximum simplicity of use. Facing with such glue can be done even to those who have no construction skills. The only nuance is the possibilities of application that are limited to an exceptionally simple process of decorating from non-heavy elements.

The advantages of choosing a dispersion solution are:

The advantages of choosing a dispersion solution are: - ease of layer formation;

- uniformity of application of the solution;

- a long period of frozen, which allows you to adjust the position of the tiles;

- no need for self-catering.

Important! If you prefer exactly this type of solution, note that the price is significantly higher for this tile glue, but it completely corresponds to the entire complex of advantages.

- Two-component compositions. Epoxy resins or polyurethane are used as the basis for these adhesives. The epoxy type is suitable for the ceiling finishes, differing fast friction, and for grouting seams. Polyurethane compositions are distinguished by very high elasticity, due to which they are perfectly combined with any type of surface and a type of tile. All solutions are prepared independently by mixing individual components immediately before starting work.

Advantages of such adhesives:

Advantages of such adhesives: - excellent strength characteristics;

- the ability to independently regulate the speed of frost;

- efficiency due to sufficient minimum layer thickness;

- the possibility of decorating seams.

What manufacturer is better?

To date, the species series is presented more than a hundred producers. Therefore, a natural question that occurs when a solution is selected: "What manufacturer to give preference?".

In this regard, it is difficult to give unambiguous recommendations, you can only take into account some criteria:

- term of existence on the market;

- specified indicators of technical characteristics;

- species row

- customer reviews.

Given only those brands that differ in positive characteristics, the following brands can be distinguished from the variety.

Ceresit.

The most popular in this area and uses the unpaid demand for all products for quite a long time. If you prefer this manufacturer, consider the following features of the use of different types of Ceresit glue:

- CM 9 - composition designed for internal works and wet environments.

- CM 11 Use for outdoor cladding and formation of flooring.

- CM 12 is a solution whose component composition meets the requirements for attaching large-format and heavy tiles.

- CM 17 is an excellent option for complex surfaces from any type of materials, including glass, wood and drywall.

Unis

Yunis tile glue is one of the most popular products of domestic production. It has a good price-quality ratio. It is represented by a fairly wide line of species, so that it is possible to choose the appropriate composition for a specific task. Some, but not all, from the most sought-after species are shown in the list below:

- Yunis XXI is a primary solution of universal meaning for lining of brick and concrete walls. It is good for fixing the tiles of small size - no more than 300g / 100cm3.

- UNIS 2000 is focused on the possibility of laying the tile, both on the vertical surfaces and for the formation of the floor covering. Application is allowed when finishing the bathroom.

- UNIS Plus is recommended for working with complex surfaces. Great for the formation of a pattern in the direction from top to bottom, which eliminates the need to lay the semi-high elements under the ceiling.

- UNIS Pool is designed specifically for use in constant humidity. Suitable for finishing the surfaces of bathrooms, pools, water tanks, artificial reservoirs. As a material, you can use tiles from any material - ceramics, natural stone, and there are no restrictions on the size of the parts. An important nuance - the location of the surface is not fundamental, that is, it is permissible to use for finishing inside the building, and outside.

- Unice Granite is used when adjusting surfaces from heavy slabs.

Knauf.

Adhesive Tile Knauf is one of the leading European brands that enjoys unpaid demand in our country. Among the species series, separately note the most demanded compositions:

- KNAUF FLIESEN is a standard solution for simple facing works.

- KNAUF FLIESEN PLUS is characterized by higher adhesive properties, which allows it to use it for any surfaces that do not differ complexity of the relief or surface material, when performing not only internal, but also facade works.

- Knauf Flex. This development is intended solely for the formation of a decorative coating of large-format tiles. Given the resistance to temperature increase, up to 80c, it is possible to use this solution when finishing the "warm" floors.

- Knauf mramor. The adhesive of this type has white color, which allows it to be used to decorate the surfaces with transparent and small elements. In addition, the features of the complex of components are suitable for solving problems when cladding complex surfaces, such as slippery glass or polished marble.

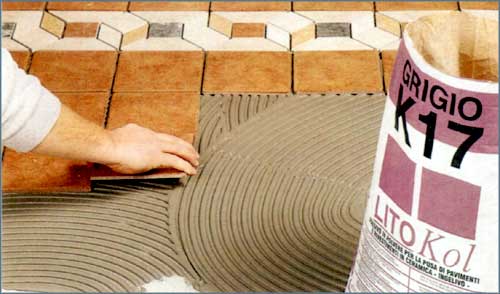

Litokol

Italian production of solutions of various types that resistant holds leading positions in the international market due to the variety of its products and high quality. Of the most interesting compositions, we note the following:

- Litoflex K80 ECO is characterized by high plasticity and frost resistance, which allows it to be used for internal, and for external cladding with ceramic and porcelain tiles of vertical and horizontal surfaces. But the main advantage of such a solution is the minimum amount of dust formed.

- To 47 - Universal tile glue for work inside a building, which is permissible to use on the walls and when finishing floors.

- Litoflex to 55 is excellent for decorating and laying a transparent tile due to its white shade. The features of the strength characteristics allow you to use the cladding method on the old tile coating and with the arrangement of the "warm" floors.

- Litostone to 98 / to 99 is distinguished from the entire species row as short as possible time. The composition contains components that ensure resistance to the effect of moisture and low and high temperatures, which allows it to be used in facade and complex conditions of operation within the building.

- Litofloor to 66 is designed specifically for laying a large-format heavy floor tile and operation of such a surface under conditions of constant high pressure loads. All facing work can be carried out even on an uneven surface.

- Litokol X 11 is applicable for finishing walls and floors in fine-format tiles. Refers to the category of reinforced solutions. Use when placing pools.

Video

Review the applied video seminar on the topic: "The right selection of tile glue" to absolutely confidently make your choice.

Conclusion

Require with all attentiveness and accuracy of the selection of adhesive composition. Be sure to take into account all the criteria and features of both the implementation of installation and subsequent operation. Use the selected glue exactly as recommended in the instructions. Only in this case the result achieved will correspond to expectations.