In order not to stay in the winter in a cold apartment, you should take care of the replacement and installation of heating radiators. As you know, old batteries that were installed at the time of the construction of the house do not always cope with their functions after the expiration of several years of service. Solve this question can install new heating devices, as well as installation of a high-quality thermal conducting pipe system. In order to reduce the cost of the cost of replacing the heating units, you can disassemble and install radiators with your own hands without resorting to the help of specialists. And the process of installation and dismantling begins with the right choice of new heating radiators. We will tell about this and many other things further in the article.

Content

When should I change heating radiators?

Let's figure it out in what cases old radiators need to be changed to new:

- On old batteries, mechanical damage was detected. This is possible as a result of sudden water pressure drops in the system.

- On radiators there are traces of sublishes or minor streams of water flowing. It occurs as a result of dilapidation and wear of heating devices.

- Batteries do not warm, although there is a sufficient flow of the coolant. This is possible due to the formation inside the mineral sediment system, which impede the full passage of warm water through the system.

- The power of the device is not enough to heat the existing area. This is often found in apartment buildings where old type convectors are installed.

- Radiators installed in your home are not effective and have a small efficiency. This problem is particularly relevant in suburban structures, where heat supply is not regulated centrally, and independently.

- Connecting new heating radiators is necessary if there are cracks and traces of windiness on batteries. This can lead not only to the absence of heat in the house, but also to the complete emergency breakdown of the system.

Selection of batteries for home: types of products and rules for their choice

Types of radiators

You can create a high-quality system of heating in your home only if there is good radiators with sufficient power for this.

There are several varieties of batteries, each of which has its advantages and disadvantages. Consider this question more.

Depending on the material of manufacturing and fastening method, radiators distinguish:

- Steel.

- Aluminum.

- Cast iron.

- Bimetallic.

- Floor convectors.

- Convectors for plinth.

Main producers of radiators:

- Buderus (Germany).

- Kermi (Germany).

- Korado (Czech Republic).

- Charleston (Germany).

- Rifar (Russia).

- Royal Thermo Biliner (Italy).

- Zehnder Charleston (Germany).

- Delonghi (Italy).

- Arbonia (Germany).

- Global Style (Italy).

- Purmo (Finland).

- Israp Tesi (Italy).

Steel batteries

They may be:

- Panel.

- Tubular.

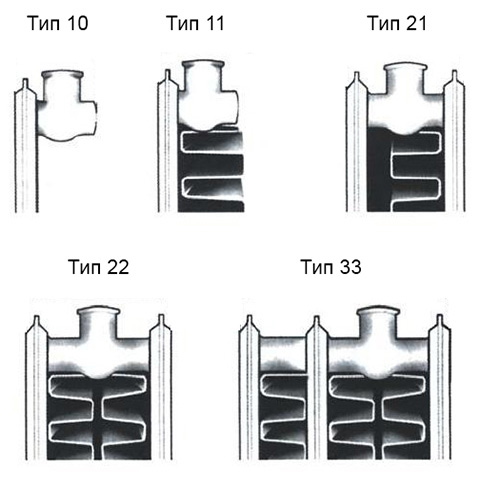

Panel batteries. Consist of several bonded panels (usually up to 3-4 ppm), between which the convective element is placed. Have a fairly high efficiency (up to 70-75%). The working pressure of these devices is an average of 7-9 bar. It is possible to divide them depending on the labeling of the device. The first digit in the marking shows how many panels are in the radiator, and the second - how many convective elements are present. Such heating devices are budget, so available to a wide circle of buyers.

Advantages of steel panel radiators:

- Budget. The devices have a fairly low cost.

- Ecology. Can be installed in children's rooms.

- Efficiency. Consume a small amount of energy.

- Good heat transfer indicators.

Disadvantages of steel panel radiators:

- Proposed to the formation of corrosion.

- Unstable to hydrowards.

- They are not recommended to use in high-rise buildings.

Tubular type radiators. Consist of several bonded pipes made of steel. According to the design, water circulates, giving heat into the room. The working pressure of these devices is an average of 8-11 bar.

Advantages of steel tubular radiators:

- High working pressure.

- Efficiency. Consume a small amount of energy.

- Good heat transfer indicators.

Disadvantages of steel tubular radiators:

- Pretty high cost.

- Proposed to the formation of corrosion.

Aluminum radiators

The main material from which the batteries of this type are manufactured, as clear from the name, is aluminum.

Aluminum radiators can be:

- Pillage.

- Extrusion.

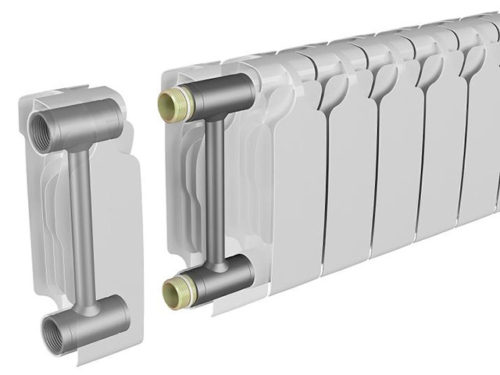

Pintling batteries Made by high-pressure casting technology. Have several sections, several of which can be removed or add if necessary.

Extrusion batteries Made from aluminum alloy with an extruder. The technology of their production is considered less expensive than the manufacture of cast radiators.

Advantages of aluminum extrusion radiators:

- They have a small weight, so massive fasteners are required for their installation.

- Efficiency. Consume a small amount of energy.

- Have a beautiful design.

- High heat transfer.

Disadvantages of aluminum extrusion radiators:

- Possess weak convection.

- Have a fragile connection between sections.

- Unstable to hydrowards.

- There are not a long service life (10-15 years).

Batteries from cast iron

Cast iron radiators, as clear from the title, are made of durable cast iron. Are the oldest type of batteries. Their appearance is familiar to every tenant at home.

The advantages of pig-iron radiators:

- Durability. The service life exceeds 45 years.

- Strength. Cast iron is characterized by good strength indicators.

- Not subject to corrosion.

- Save heat for a long time, even after turning off the coolant feed.

- Have a relatively low cost.

Disadvantages of piggy radiators:

- Have a lot of weight, so they need durable fasteners.

- Heated long.

- Unstable to hydrowards.

Bimetallic radiators

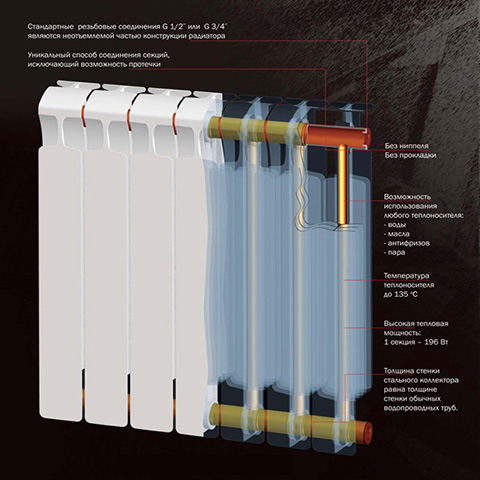

Bimetallic radiators are the most modern type of heating devices. They are combined devices, they combine steel tubular core and aluminum shell.

Advantages of bimetallic radiators:

- Sustainable hydrowards.

- High working pressure.

- Have a beautiful design.

- Corrosion resistant.

- Installation of such devices is quite simple.

- High heat transfer.

The disadvantage of bimetallic radiators is considered their high price.

Floor and Plinth Convectors

Floor and plinth convectors are the newest solution in the field of home heating. Convectors are small attic elements of which are boxes, coolant and an external decorative grill.

Advantages of convectors:

- Non-futured installation.

- Small sizes of the device.

- The ability to "hide" under the floor or plinth.

- Construction strength.

- Corrosion resistant.

Disadvantages of convectors:

- Low heat transfer.

- High price.

Selection of batteries for home

What first should be paid when choosing batteries:

- The strength of the product. The presence or absence of an emergency in a residential building depends on this. Characteristics of strength are indicated in the technical passport of the device.

- Corrosion resistance, rust. These indicators affect the wear resistance and operational characteristics of heating devices.

- The level of heat transfer. This indicator depends on how efficiently the device will cope with their directness of the heating of the room.

- Quality painting devices. Since often batteries have in their composition component elements from metal and steel, which are subject to corrosion, the quality of their painting plays an important role. Before purchasing radiators, carefully inspect all sides of the product for roughness, cracks and defects in the paint bed.

- The number of sections in the radiator. If we are talking about sectional radiators, then the more sections they have, then they have greater performance.

In order to choose a suitable unit for your room, you can use the calculator calculating the number of radiator sections. To determine this value there is such a formula:

- Ks \u003d 100 * (PC / TM);

Where:

- COP - Number of battery sections.

- PC - Room Square, Measured in M2.

- TM - thermal power of one section, W.

Replacing the heating radiator with their own hands

Tool for replacing heating battery

Before starting work, you must prepare a plumbing tool for the installation of radiators with their own hands. It is better to do this in advance so that during the work of the work, do not waste the time in search of the desired key.

To replace heating radiator, you will need:

- Soldering iron solder plastic pipes. This tool is quite expensive and in order to replace one battery, it is not worth buying it. Now many specialized stores can rent it. To replace the entire heating system in the middle house enough two days. If the work is performed for the first time, it is better to do and take it for a week. If the pipes are metal-plastic, the soldering iron is not needed.

- Bulgarian with cutting circles. A circle with a diameter of 125 mm will be quite enough.

- Set of keys: Rozhnik 36x41, pipe number 2 and divorce # 3.

- Perforator and drill with a carbide tip. If the wall brick drill can be an ordinary drill.

- Roulette, level, pencil.

- Pacle or other seal for threaded connections.

Dismantling old battery

The process of dismantling the old battery directly depends on the state of the existing pipes of the coolant supply and the need to replace them.

If the old battery is installed on new metal-plastic or plastic pipes, the replacement process is as follows:

- Cranes are overlap that cut off the battery from the entire system.

- Carefully unscrew the catch nuts from the couplings.

- The battery is removed from the mounts.

- Couplings are twisted from its body.

If a new battery is installed in parallel with the replacement of the pipe, then the latter is simply cut with a grinder, and then unscrewed from the battery body.

The most difficult to work with steel pipes, if they are planned to be saved for further operation. In this case:

- The pipe is cut off from the battery at the required distance.

- Then out of the battery case gets out the remaining fixtures.

- Body left pipe is cut or welded on a new thread.

- To her screwed fitting a new battery.

- After dismantling of the old heating radiator is necessary to remove the brackets that held him.

- When the work is finished, you can begin the installation of the new battery.

Installation of the new battery in the plastic pipes

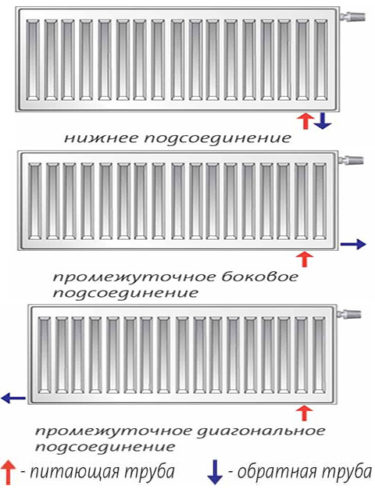

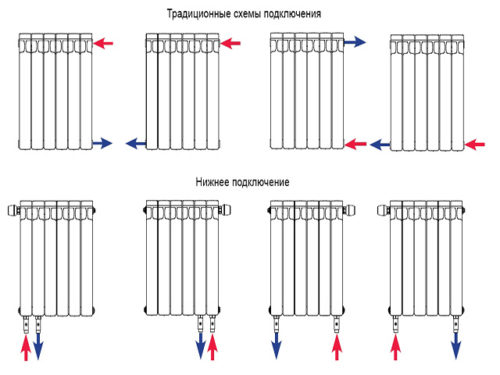

Radiator connection scheme:

Procedure for work:

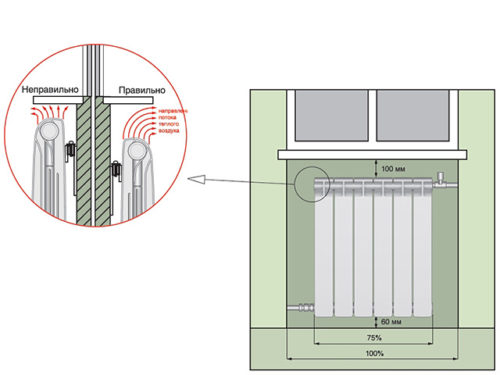

- Before starting work, the new battery must be prepared. Next, apply the room layout of the installation of radiators.

- Then you need to screw couplings. To this end, the outer sleeve thread wound sealant. Mastic is the thread must be only in the direction it turns. For right-hand thread - in a clockwise direction for the left hand (very rare) - counterclockwise.

- The coupling (so-called "American") has a union nut on the end of which is freely rotating. To her screwed shut-off valve. Its outer thread sealing mastic is also pictures. When tightening is necessary not to forget to put the gasket.

- Then the faucets screwed joints for metal pipes. It is screwed into the valve. Mastic is also carving. The battery is now ready and can be installed on the workstation.

- Further, it is necessary to attach to the pipe. Should be guided by the wiring diagram to the radiator system. The battery must be installed on the stand so it will not drop.

- Further, with sleeves which are fastened to the shut-off cocks, are removed and the nuts and retaining rings fit over the tube. The tube is then put on the coupling pin and the nut is clamped.

- After that you need to outline the space for mounting hooks. They must be checked by the level. Otherwise, the battery will be installed crooked. Now you can unscrew and start the installation of hooks. For this purpose, the wall drilled hole, set anchor, and pumped into the hook. Further, the radiator is put in place and re-connected to the system.