Caring for the preservation site is not quite easy. Even six hectares of the garden is quite enough to bring a lot of problems to their owner. And if we are talking about hectare or more, then it is suppressed. Thanks to technical progress, many mechanized labor tools appeared on the market, which significantly facilitate the work of the gardener. This is a mini motor blocks, motocos, automatic watering systems and plant fertilizers, and, of course, motorcases. If in Soviet times, such devices were predominantly professional wood rollers, and the notorious "friendship" was in households rather than the dicky, now the situation has changed. Chainsaw is already considered to be needed than luxury.

Content

- How to understand that chain chainsaws need sharpening?

- Because of what chain chainsaws comes in disrepair

- How to make a sharpening chains for chainsaw do it yourself

- How to sharpen chain chainsaws with your own file with your own

- Sharpen chain chainsaw on the machine

- Care of the saw headset chainsaw

- How to sharpen chain chainsaws with your hands with a grinder: photo

- How to sharpen chain chainsaws with your own hands: video

Thanks to the chainsaw, garden care will be a simple occupation. In addition, it can be easily selected for a dacha furnace or a solid fuel boiler. Like any mechanical tool, chainsaw requires attention and care. This is especially true for the engine and chain. The internal combustion engine must be constantly lubricated, carry out maintenance, pour with a special lubricant with gasoline. The chain care on which the cutting teeth are located is mainly sharpened. About how to sharpen chain chainsaw friendship with their own hands - further in the article.

How to understand that chain chainsaws need sharpening?

The fact that there was a need for sharpening chainsaw chains, an experienced user will learn from the features of her work:

- The first sign of problems with the sharpness of the teeth is a significant reduction in the speed of the cut. Moreover, the performance fall is observed not only when working with solid wood, but also with soft wood rocks.

- Another indicator of the need to sharpen the chain is a small chop that flies out of the cut, and if it is painted in black, it says about the fully fastened chain. In this case, it is imperative to apply the measures.

- The beginning of chain problems can be felt through high vibration when working with a tool. Already at this stage it is necessary to take action.

- Reducing the severity of teeth leads to an increase in the load on the engine, its overheating and excessive wear.

Because of what chain chainsaws comes in disrepair

The reasons why chain chainsaws can be disretened to several:

- The most common among them is working with solid wood. Cutting solid rocks must be carried out gradually, without giving a tool too overheat.

- More often, the teeth of the chains are stupid when contact with metal or concrete surfaces. So that this does not happen, it is necessary to be attentive in the work of work, prevent the cutting of trees near the surface of the Earth and near the location of the branches and branches. The fact is that the bitch has much greater hardness, which adversely affects the condition of the cutting edges of the chain.

How to make a sharpening chains for chainsaw do it yourself

Sharpening the chain with your hands - the process is quite complex, and to do it properly, you need to know some of the nuances. After work, the chain must match the settings that are laid manufacturer. This is very important since the motor parameters, the drive sprocket is calculated based on the characteristics of the saw chain. If she will not meet them, the tool may not work correctly. You can not be too grind the teeth, changing their geometry and dimensions. Such actions can lead to uneven wear and tear the circuit, which is always very dangerous.

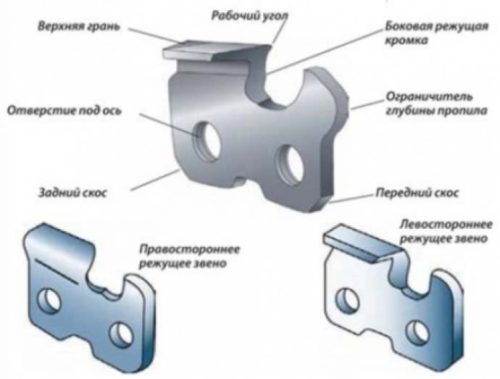

When sharpening the chain needs to know its structure. chainsaw chain consists of cutting links: right- and left-hand drive, the configuration in which the mirror. Established links in turn.

Needless link consists of several parts:

- Front and rear ramps.

- Holes sleeve axis and which connect the chain together.

- Cutting depth limiter.

- The upper bound.

- The operating angle.

- The lateral cutting edge.

It is the severity of the last two parts of the effect on the operation of the entire instrument, so they are sharpened.

Sharpen the saw chain in two ways:

- Manually, using a special file.

- At a special grinding machines.

Sharpening using the machine makes sense for large volumes of work, when the tool has to serve often. they are usually used in the machine shop companies on the harvesting and processing of timber. Buy a machine that costs not so little, in order to sharpen the chain a few times per decade, it makes no sense. Grinding of the teeth by hand, though time-consuming, but not as "pretty penny".

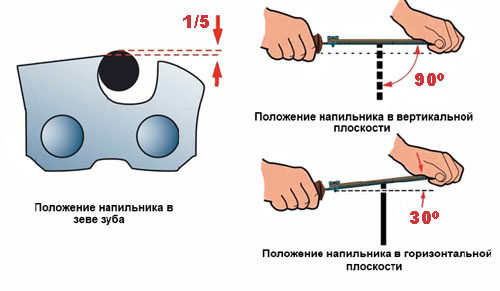

How to sharpen chain saws with their hands a file

Since the cutting edge of the chain link has a semicircular profile for sharpening it can be used only round file. In this process, an important step will be the selection of a file. Poorly chosen tool not only complicate the work, but also make the result unpredictable, which can lead to tragic consequences. Selecting a file should be performed depending on the configuration of the chain link and its step. The last parameter from the standard chains ranges from 4-5.5 mm. When the tool must not protrude beyond the tooth face of more than 1/5 of its diameter. To achieve normal cutting parameters sharpening angle should be 30 °. It is at such an angle to the horizontal instrument should be kept at hand sharpening saws.

Manufacturers chainsaws tend to offer a complete set of tools for sharpening chain. Typically, it includes:

- round file with the tool holder,

- a small flat file,

- special wiper blade.

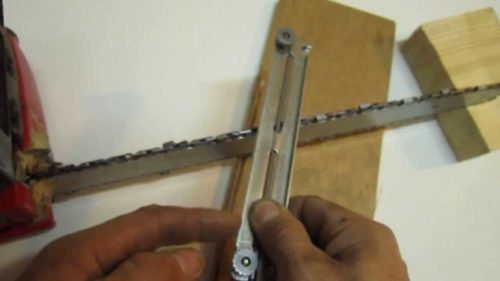

Due to a file with the tool holder, on which a special mark, the work becomes more accurate with it. Due to the fact that the plate rests on the tool cutting depth limiter, and the upper part of the tooth itself file takes the desired position directly above the cutting edge, which makes the process more precise grinding.

The process of sharpening the saw chain with a file in the following order:

- First we need to clearly pick up files for sharpening chain saw chains, which diameter corresponds to the profile of the cutting edge.

- Bus chainsaw must be tightly fastened. It must be done very carefully so as not to disturb her original configuration. If you bend the bus, all tools can come into disrepair.

- Then, the chain brake is set so that it not rotate during grinding.

- The next step should be noted first working tooth. This is done so as not to sharpen the teeth of the second round.

- Files installed into the operating position and starts sharpening itself.

- Tool movement should be smooth and without jerks, only in one direction (away from you).

- At work do not need to click on the file too, so as not to grind off a larger layer of the tooth.

- For each tooth the chain process has to be identical, including the pressing force and the number of passes of a file. The only way to achieve a uniform sharpening tools.

- When working with a file must be slightly rotate around its axis. This will provide a more uniform wear of the tool, which will guarantee the same whole Sharpening the saw in the future.

- First sharpen the teeth in one direction. After that saw turned over and continue to work in the opposite direction.

- If the chain teeth are not the same length, then it accepted the shortest of them as a template. All other sharpened for him.

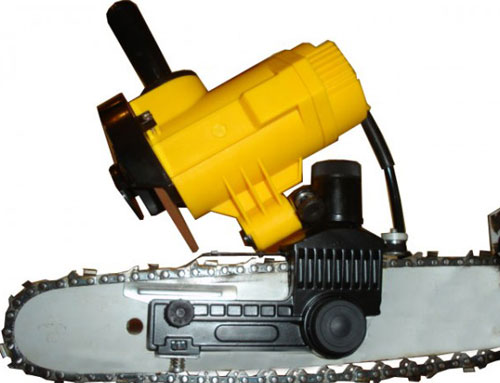

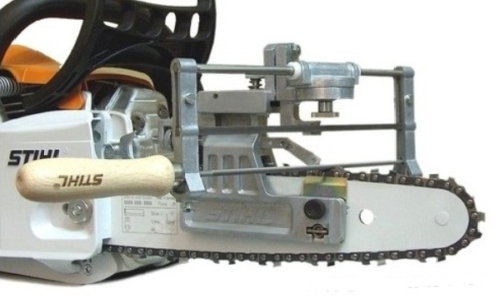

Sharpening the saw chain on the machine

The advent of mechanical and electrical machines for sharpening chainsaw chains greatly eased the task. Now, configuring the machine for the smallest tooth, you can easily do all the chain teeth are exactly the same. This moment is distinguished from the mechanical hand sharpening.

The process of sharpening the saw chain on the machine is quite simple and requires no special knowledge:

- First of all, the saw is installed in the machine. It is done in such a way that her teeth looked at the sharpening stone.

- The chain tension screw must be sent.

- Next sets the angle of incisional stone. This is the angle of sharpening, the most optimal value of which is 30 °. However, this parameter may vary depending on the recommendations of the manufacturer's manufacturer.

- Usually the process of sharpening chains chainsaws are carried out through the tooth. It is much more convenient than to make a consistent sharpening.

- Sharpening tooth should not be too deep. This can lead to a decrease in link strength, which when working can simply collapse.

- After the end of work, it is necessary to remove the remains of chips and abrasives from the surface of the chain, and then lubricate it with engine oil.

Care of the saw headset chainsaw

To the chain of saws served for a long time and less tupped, it is necessary to care for it.

The chain care lies in its timely sharpening and lubricant:

- As for sharpening, the chain must be maintained in a chromium layer. It is applied to the surface of the teeth for greater sharpness. With a timely sharpening, the chrome layer remains unscathed, which is the key to the sharpness of the chain. If you allow the state of the teeth before damageing the chromium layer, it will be fatten quite often.

- Also on the operational properties of the chain affects timely lubrication. It is served from the oil pump inside the saw of the saw. Check the lubricant can be presented with a sheet of paper to the tire of working chainsaws. After a few seconds, lubricant spots should appear on paper. Before installing the new chain, it is sprayed with an oil aerosol in the tire.