The use of brick ovens today is quite extensive. They will suit not only for the heating of houses and for cooking, they can still be used to heat the equipment buildings, baths, for hardening metal products, as well as as a manga, barbecue. For the heating of small rooms, such as a garage where it is necessary not too high, it is advisable to use small brick furnaces. The only one should not use brick furnaces for heating of greenhouses, greenhouses, cattle pens. About how to make a brick furnace for a private house with your own hands - let's tell later.

Content

Brick oven. Characteristics of construction

Advantages of brick stoves a lot:

- The most important advantage is the simplicity of design and low cost of materials required for construction. If you compare such a installation with small metal aggregates, then the difference in the price of production will be significant. The fact is that for the construction of a brick furnace, it is not necessary to use electric welding, as in the case of metal structures. And this in the conditions of a country house is a fundamental factor. Yes, and the cost of red and chamotte brick is incomparable with the cost of metal rolling.

- Master the wisdom of brick masonry in a short period of time, which cannot be said about metal welding. And for the construction of a brick furnace, Russian does not need to buy a welding machine, which costs a lot of money.

- Also the advantage of such structures is the average thermal conductivity of the material, which allows you to maintain a comfortable temperature for more time.

The disadvantages of brick furnaces include it that it is impossible to transfer it if necessary for a new installation site, unlike a metal unit. Also, the installation of such a design should be carried out only on the prepared foundation, because otherwise the laying of the furnace can collapse.

Male accommodation units with a small cubage are used primarily, which does not require high energy for heating. This option of heating is most suitable for cottages when the country village is not gasified. More furnaces on firewood are perfectly suitable for heating garages, workshops, sheds, that is, in those places where high temperatures are not needed, and, accordingly, the high power of the unit. In this case, the furnace on firewood will be able to save fuel.

Now consider all the important points you need to know about the brick for the construction of a brick furnace for home with your own hands, as well as for the cottages and other rooms:

- Variety of material. Basically, two types of bricks are used for the construction of a brick furnace for heating at home with their own hands: ordinary red and chamotte brick.

- Material masonry technology. It happens three main species: spoonful, chain, cross. For the construction of the furnaces, the first laying technology is usually used, that is, when the brick of the top row overlaps the bog of the bottom.

Masonry solutions apply two types:

- cement with sand or drop fillers,

- clay with sand filler.

The first is used for the screed, arrangement of the foundation and laying the first rows of bricks, then the clay-sandy solution is already used. With its preparation, you need to be extremely attentive, not allowing the occurrence of lumps (if necessary, they need to be erected by hand), as well as to withstand the optimal fat content of the mixture. The perfect solution should be slipped with a trowel, without leaving traces on it.

Installation dimensions must be seamless depending on the size of the heated room. Here it is necessary to approach individually. Unlike bourgeoque, brick furnaces have higher thermal characteristics. Based on this, even an aggregate occupying 0.5 square meters will be enough to dig a small room.

Brick oven for home with your own hands: order

Tools and materials

In the main construction of furnaces for the bath and heating other small premises, the owners themselves are engaged. Easy design and small costs of materials make the construction of these aggregates, if not simple, then not too complicated. In order to add such a design yourself, it is necessary to have an idea of \u200b\u200bthe basic materials for the production of work and the sequence of action during installation.

For the construction of a brick furnace, we will need:

- cast iron metal damper,

- galvanized pipe for the construction of chimney,

- the door for the furnace

- master OK,

- brick,

- solution.

Brick oven for home with your own hands: Projects

The first stage of the furnace production is planning and design. Here you need to foresee the following nuances:

- It is important to determine the exact dimensions of the furnace, depending on the area of \u200b\u200bthe room, which will be heated. This all should include the drawings of a brick oven for the house built with their own hands.

- For a large oven, it is necessary to build a separate foundation. It is impossible that the basis of the house and furnaces are related to each other.

- If a cooktop is built, which meets all safety requirements and standards, it can be erected without a separate foundation. However, flooring under the furnace should additionally increase durable lags.

- The chimney of the furnace should be built so that it does not come into contact with the supporting beams on the ceiling.

- The chimney of the furnace must be located above the roof skate by 60 cm.

- Since all Russian ovens, given the feature of their masonry, consist of 1400-2500 bricks, then it should be equipped with a separate foundation that does not connect with the basis of the main building.

Design of the furnace

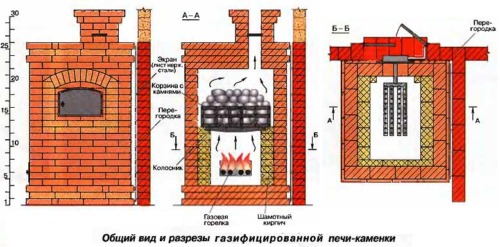

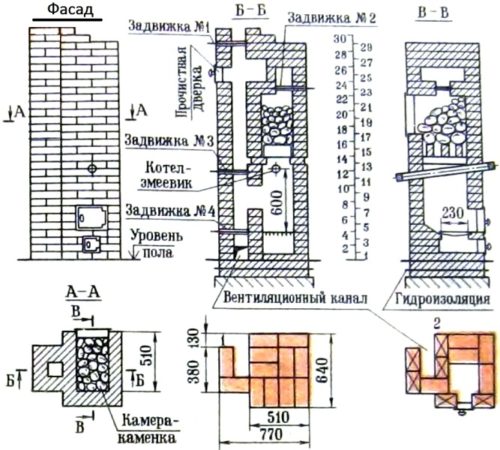

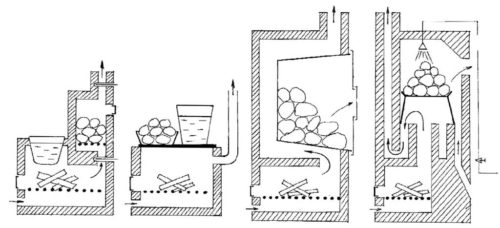

Most often, massive and large brick furnaces consist of several structural elements:

- The body of the furnace.

- The foundation is the basis on which the oven is built. Most often reinforced concrete basis.

- The layer of hydro and thermal insulation. Usually used for heat insulation rubberoid. It is placed in a layer of at least 3 cm.

- Shanses are supports, which are constructed to save building material. If they are presented, there is no need to build a reinforced concrete basis, and it can be limited to a simple tape.

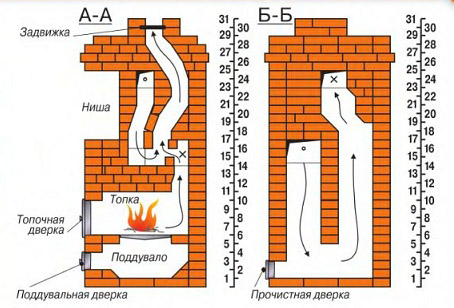

- Pissed. Niche and door.

- Air canal (drying).

- Grate.

- Arch and mouth furnace.

- Hole to clean the oven.

- Air convector drying.

- Chimney.

- Fireborne cutting.

For each furnace there is a laying scheme. It schematically shows all stages of masonry work, ranging from the installation of the foundation, ending with the structure of the chimney.

Laying a brick furnace with their own hands for the house

There are several brick laying options for facing furnaces. The most commonly applied spoonful and tych technologies. It is less likely to meet a design posted on bed laying technology. Moreover, according to technological standards, it is categorically not suitable for building furnaces.

So, let's start laying the furnace for cottages and other small rooms:

- First of all, you need to pour the foundation for construction. To do this, dig a small pit, a little more oven size, fall asleep in it sand and pour it with water so that it is a little donkey. The thickness of the sand layer must be 15 cm. Then with a layer of 25-35 cm we fall asleep crushed stone or screening. You can use other building fillers. The crushed stone layer is thoroughly tamped and a litter of rubberoid lies on it. Then the screed is poured. After drying on it, another layer of rubberoid is placed.

- We begin to put the material. On the dried and isolated foundation lay a layer of red brick size 2x2.5 stone. Please note that it is posted strictly horizontally (check the level), and the corners of the layer were straight.

- We lay out the second row of bricks, but no longer solid, but only edging. The second row will serve as a coach for the furnace door.

- We establish a flue door in which to improve the thrust we drill several holes. In order for it does not fall, when placing bricks, you can bind it to galvanized wire.

- Out the door with bricks. If you need, the material directly above the door must be cut so that it gets up smoothly. Next, put three more bricks.

- Then they put the fourth row of bricks on the edge, so we cover the furnace, and the outlet of us becomes the size of only one brick.

- The following series of material is again stacked on the bed, spoon inward and outward.

- Then the next row stacked on the edge, and after - to bed, thereby narrowing the upper part of the design to the size of one brick. After that, the flap is installed.

- Next, the chimney is adjusted for the size of the metal pipe, which is then derived outward. If you are going to do chimney from a galvanized pipe, then the minimum distance to its end from the furnace should be 1 meter, and the more it will be the better in the traction oven.

After the end of the work, do not hurry to turn the unit. He needs to stand at least a week to froze the solution. By the same technology, a large brick oven is built for a two-story house with their own hands.

The construction of small brick stoves has recently become a rather popular occupation. Indeed, with a simple design and the minimum set of necessary materials, such aggregates will be practical and economical heating devices for small rooms. At the same time, possessing small skills of working with brick and solutions, as well as basic knowledge in construction, such an installation can be built in a couple of days.

Unlike metal furnaces, brick aggregates pretty well keep the temperature, evenly distribute heat over the entire area of \u200b\u200bthe room. In addition, they are slower than cool. For the production of such a furnace, the implementation of welding works is not required, which is quite important for not electrified premises.