An important meaning when choosing heating radiators play their aesthetic and heat-conducting qualities. In this case, aluminum radiators, having the highest thermal conductivity indicators with respect to other types of heat exchangers, occupy leading positions. However, they are issued by various manufacturers, they can differ significantly not only on heat transfer, but in many other indicators.

Content

Advantages and disadvantages of aluminum radiators

For a change, improved heat exchangers, represented by steel, aluminum and bimetallic heating devices, came to replace the heating radiators. Of all the variety of various kinds of heating batteries, aluminum radiators are still in the greatest demand. Moreover, the interest of the population is aluminum heat exchangers due not only to an excellent thermal conductivity coefficient, but also such advantages as:

- compactness;

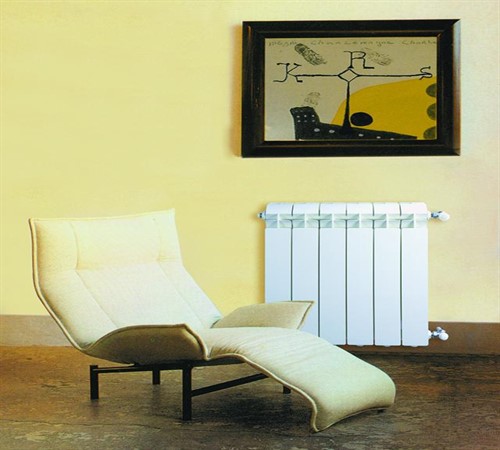

- aesthetics;

- a large diameter of the cross section of intercolette pipes that prevents rapid clogging of the radiator;

- the speed of heating / cooling due to the small volume of the aluminum radiator;

- the ability to control the heating temperature of the battery through thermostatic elements;

- the ability to adjust the radiator power by reducing / adding sections;

- low weight;

- ease of installation;

- service life, variable in the range of 10-25 years;

- acceptable cost.

In addition, the high-quality coating of radiators of the powder enamel in the factory setting eliminates the need for their periodic staining. As a result, in the process of heating the battery in the air, toxic elements contained in any paint products will not be released. At the same time, the aluminum alloy used for the manufacture of heating radiators is also a safe material that does not emit any harmful connections when heated. Based on these conclusions, aluminum heat exchangers are completely safe for health, which you can not say, for example, about painted cast iron batteries.

Despite the mass of advantages, aluminum batteries also have a number of flaws:

- Relative resistance to sharp pressure jumps.

- The probability of the appearance of leaks in sections of sections.

- The need to periodically get rid of the air-accumulating air through aircraft valve to avoid recent system.

- The possibility of corrosion formation as a result of increased acidity of the coolant.

- Aluminum incompatibility with steel and copper pipes that contribute to the occurrence of electrochemical corrosion.

However, any disadvantages can be considered conditional. For example, well-known manufacturers of aluminum radiators (Italy, Hungary) carry out anti-corrosion treatment, protecting the heat exchanger for a long period of the occurrence and progressive corrosion development. In addition, an aluminum alloy is used for the production of radiators, and not metal in its pure form. In this case, the admixture of copper, zinc, iron significantly reduce the resistance of the finished product to corrosion, thereby reducing the operational period. Therefore, the risk of corrosion in the process of operation is quite relative.

Thus, aluminum radiators can be used both for autonomous and for central heating systems. However, knowledge of deficiencies will minimize their manifestation during operation.

Types of aluminum radiators, their characteristics

Some advantages, along with the lack of aluminum radiators, depend on the method of their production. Therefore, based on manufacturing technology, radiators are divided into 2 types:

1. Alloy - are separate sections cast under high pressure. At the same time, the collector is welded to already hardened elements. The assembly of individual sections is carried out by means of special nipples. For reliability, the docking compound is sealed with high-temperature silicone, paronit gaskets and other similar materials. Aluminum sectional radiators can produce any form, since the hot alloy is poured into pre-prepared forms, where the process of the rejection occurs. Radiators obtained in this way are distinguished by a smooth surface and accurate dimensions.

Compared to extrusion radiators, cast aluminum possesses the following advantages:

- the possibility of forming radiators of the required length;

- the ability to replace damaged for any reason for the section;

- the presence of inner plates that contribute to an additional increase in heat transfer coefficient;

- high strength due to construction monolithium, as well as greater wall thickness.

2. Extrusion - presented by the collection structure obtained as a result of the softened aluminum alloy through the calibrated holes of a certain section. The compound of the elements obtained from the top, and also the bottom part is carried out by electrochemical welding of either the composite glue. Radiators made by extrusion are characterized by relative ease of products and sufficiently attendant forms caused by the presence of sharp protruding elements.

The distinctive features of extrusion radiators are as follows:

- increased resistance to pressure drops;

- reliability because there are no intersection joints;

- the impossibility of increasing the radiator;

- little weight;

- low inertia, contributing to a faster battery heating.

Despite all the advantages of extrusion radiators, sectional heating structures are most popular. At the same time, the price of aluminum radiators is somewhat higher than on extrusion.

In a separate category of aluminum radiators, it is worth highlight anodized batteries that are made from high quality aluminum. The essence of the process is that the aluminum purified impurities are oxidized using the anode. Such an impact significantly affects the structure of aluminum, endowing it with increased resistance to corrosion. In addition, the connection of individual elements is made from the outside by means of special couplings, due to which the inner surface of the radiator remains smooth, contributing to an excellent heat transfer of the product. In addition to the existing advantages, the anodized batteries also have a high working pressure. However, such radiators are quite expensive, so practically not in demand.

Thus, various types of aluminum batteries have certain advantages and minuses, the degree of importance of which must be considered based on the characteristics of the intended exploitation.

Criteria for selecting aluminum radiators

Going behind the batteries in the store, I want to purchase the best aluminum radiators that would serve quite a long time. However, a wide range of highly makes it difficult to search for a suitable model. Therefore, choosing aluminum radiators whose characteristics are not very different from each other, it is worth paying attention to the following factors.

Manufacturer

Currently, the market there are radiators produced in Italy, Poland, Hungary, China, etc. At the same time, Italian production radiators (Global, Fondital), compared with Polish or Hungarian, have higher quality contributing to an increase in the operational period of up to 25 years. However, such radiators are distinguished by quite high cost. In turn, inexpensive, Chinese heating radiators (Epico, Maxterm) will serve as a maximum of 10 years. Thus, if the financial capabilities still have to acquire expensive option, then the problems with the radiator can be forgotten by at least 20- 25 years.

Dimensions of radiator

Before you choose the choice of a suitable radiator, you need to measure the area designed to install the battery. The fact is that the distance from the floor to the battery, as well as from the battery to the windowsill, should be 7-10 cm. At the same time, there should also be a gap of 4-5 cm between the wall and the battery. Such indents are needed not to violate natural convection, Contracting an increase in the coefficient of heat transfer of aluminum radiators.

If the heating device is assumed to be mounted in a niche, then the top / bottom of the niche is taken.

Power design

An important characteristic of the heating radiator is its power. At the same time, the power of cast radiators at any time can be increased or reduced, which cannot be made with extrusion radiators. Based on this, the capacity necessary for heating the room is desirable to count in advance.

The heat transfer of one section with a height of 500 mm varies in the range of 150-200 kW. To calculate the power of an aluminum radiator sufficient to heat the room, the area of \u200b\u200bthe room is needed to multiply to its height and divided by 10. The obtained room volume is corrected by multiplying to a correction factor equal to 41 W. However, this calculation is approximate. For more accurate results, the following adjustments are added:

- for each door - 0.1 kW;

- for each window - 0.2 kW;

- for the corner room - 1.3 kW;

- for a private house - 1.5 kW.

If a fractional number is obtained, it must be rounded up to the full number in the direction of magnification.

Dividing the foundation indicator of the heat transfer to the power of one section declared in the manufacturer's passport, the minimum number of sections needed to fully warm the desired room are obtained.

Thus, the more aluminum radiators in size, the greater the heating surface and heat transfer. Consequently, the power of the design is in direct proportional dependence on the size of the radiator.

Pressure

Almost all of the currently produced models of aluminum heating radiators are adapted to significant pressure drops, therefore the working value of such an indicator varies in the range of 6-24 atm. However, heating radiators with an indicator of 6-10 atm is better to purchase for autonomous heating systems, while for the central heating system it is better to repel from 14-16 atm.

Thus, before you buy aluminum radiators, it is necessary to study all the information about the model you like, and also compare the technical characteristics of future operational conditions. At the same time, the impeccable quality of Italian radiators does not have any comparison with Chinese heat exchangers, although among Chinese products there are quite good options.