Flat roof - one of the most popular methods for overlapping buildings. Until the end of the last century, such a technique was used mainly for the roof of multi-family houses of large floors, as well as administrative buildings. Special respect, as one of the fastest ways of the roof device, the flat roof received during the construction of small buildings, such as garages, workshops, etc.

Content

Benefits and disadvantages of flat roof

The main advantage of a soft flat roof, as we have said, is the simplicity of installation. Unlike two-tie structures, with the construction of which complex calculations are required, the correct selection of materials and the complex construction process, the case with flat roofs is much easier. Such surfaces are quite simple in maintenance and repair.

In addition, thanks to a practically zero slope, its space can be used as useful. On the surface of the roof of the house with a flat roof it is possible to arrange a small lawn, a place to relax, and even the pool and tennis court. They can easily place additional equipment, such as solar collectors, satellite plates - they will be easy enough to serve. Thanks to its design, such roofs have a smaller area of \u200b\u200bheat transfer, which makes them more energy efficient.

The disadvantages of such a structure of the roof can be attributed relative to the short-term interregnation life, especially if the material was incorrectly selected or retreat in the work of work production was incorrectly. In winter, with abundant snow falling, it accumulates on the surface of the roof and when melting can cause leakage. Also, when direct sunlight gets, the bituminous coating can be very hot, which leads to the appearance of unpleasant odors.

Types of flat roofs

All flat roofs can be divided into the following types:

- Inversion. Such roofs are an upgraded type of traditional coatings.

- Operated. On such roofs, the base makes tough in the form of a screed, which allows a person to be on their surface for repair work. For such structures, it is important to correctly select the heat-insulating material, as it will experience large dynamic loads.

- Non-exploited roofs such an opportunity excluded that with their relative cheapness, significantly reduces their life.

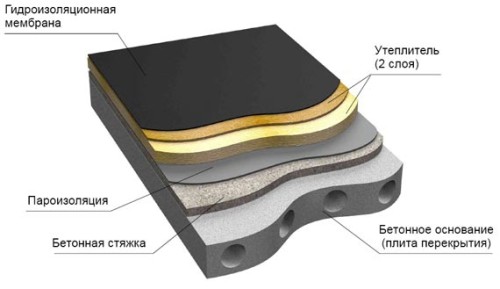

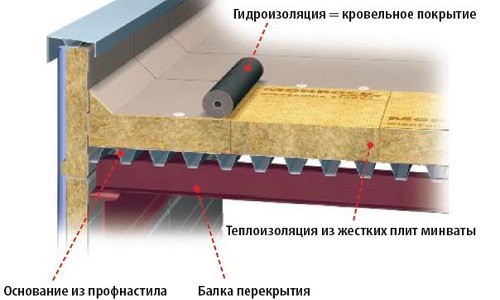

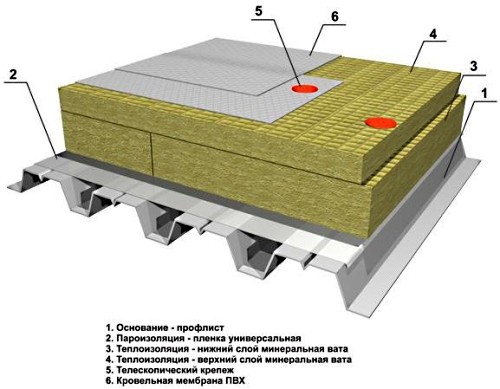

- Soft or traditional. The design of a flat roof in this case is a multi-layer "pie". Usually several layers are stacked on the reinforced concrete overlap in the following sequence:

- concrete screed;

- vaporizolation;

- several layers of thermal insulation;

- a layer of waterproofing, which is, as a rule, bitumen material, such as a rubberoid or a ruble.

Flat Roofing Materials

In order for the coating under all weather conditions provided normal heat insulation, precipitation protection and served a long time, it is necessary to correctly choose quality materials. In order not to make a mistake in the choice, it is better to consult with those skilled in the art. This will significantly save you tools, time and nerves.

List of essential materials and recommendations on their acquisition:

- A cement mortar based on sand and cement is used as a screed.

- The vapor barrier layer is a parobaric film or a bitumen-polymer membrane reinforced with fiberglass. Vaporizolation stacked over the screed.

- The insulation layer can be made of mineral wool or clay. In the case of the application of the latter, the screed is placed on it, which is covered with a double layer of waterproofing material.

- As waterproofing use rolled materials on a bitumen basis. Ruberoid or Rublesty have excellent performance.

Recently, membrane materials are often used as waterproofing, which in comparison with bitumen have a number of undeniable advantages. They have high strength, a good level of fire safety, is resistant to aggressive media, mechanical effects, perfectly tolerate direct sunlight.

Unlike Ruberoid, membrane materials during installation do not need to be heated using burners. They are mounted by a complex method, which includes mechanical fastening and chemical - with glue. Thus, the rollers of the membrane material are rolled over the roof surface and glue the joints of the canvases. Additionally, with the help of the fastening element it is attached to the base of the roof.

Arrangement of water supply

As a rule, on the flat roofs of modern buildings arrange inland drains. The funnels such structures are located in the middle of the roof, and their pipes are laid in the center of the building. The roof is mounted in such a way that the flow funnel is located at the lowest point of the waterboa square. The end of the waterproof tube is closed with a grid, in order to avoid falling into a garbage pipe, which can cause the roof flooding.

In modern buildings around a funnel for a flat roof, a cable heating system is placed so that during the spring daythane it does not freeze, and thereby did not prevent the free flow of water.

The drains are located so that one riser accounted for no more than 200 m 2 Surfaces. To prevent the flooding of the roof, if the internal drainage system is clogged or can not cope with a large amount of precipitation, in the parapets of a flat roof, an openings for emergency reset of water are provided.

Flat Roof Ventilation Device

To prevent damage to the layers of flat roof, in its designs include ventilation channels or aerators. The fact is that not a completely durable layer of vaporizolation is often damaged both when laying and during operation. In this case, the moisture, formed by the temperature difference, will penetrate the insulation layer. Since the sealed layer of waterproofing will prevent the evaporation of water, it will gradually accumulate in the heat insulating compartment. Such a state of affairs can contribute to the destruction of the structure of the roof layers and a decrease in the frequency period. In winter, the moisture clopped into the layers of the roof will expand when freezing, from which the material starts to swear, which will lead to the destruction of the integrity of the seams.

Aerators are installed in the upper points of the roofing metal or plastic pipes, covered with fungi, which due to the difference in the pressure, out of the lower layers of the roof of an excess moisture.

The device of the minimum slope of a flat roof

When installing a flat roof, it is necessary to achieve its slope in the range from 1⁰ to 4⁰. With this position, the roof is ensured by the most optimal drainage.

In order to achieve suitable water flow indicators and provide sufficient flap of flat roof for this, several methods can be applied:

- Using bulk materials, such as slag, ceramzite, perlite.

- Applying concrete mixes with fillers from bulk materials.

- Using concrete mixes with polymer fillers.

- Applying thermal insulation materials.

The most common method is considered the last. The fact is that when laying bulk layers, they can change their position, and, accordingly, change the angle of the surface. Therefore, it is better to apply the material in the plates, such as:

- Extruded polystyrene foam.

- Glassizol.

- Foam concrete.

- Mineral wool based on basalt and glass.

Method of installation of a slope using, for example, polystyrene foam is quite simple. When laying thermal insulation using a building level and substrates from waterproofing, polystyrene plates are stacked so that there is a minimal tilt. Then the concrete screed and waterproofing is placed on top.

Installation of a flat roof. Order of work

Before starting the installation, it is necessary to draw up a project of a flat roof and clearly perform it. The composition of the sketch must include a flat roof calculation in order to reliably know the number of necessary material.

Phased performance:

- Preparation of the surface. As a rule, a flat roof is mounted on reinforced concrete slabs, which often have irregularities. Therefore, before starting work, the surface must be prepared. First of all, we remove the remnants of last roof from it. Make it with a special scraper. If necessary, some places need to be treated with solvent. Then, with the help of an industrial vacuum cleaner or broom, we remove the trash from the surface - it can interfere with the dense fit of the roof to the slabs of overlapping and cause poor heat and waterproofing.

- Seeling cracks. All cracks in the ceiling plates need to be shuffled with polyurethane sealant. This will prevent the leakage of the roof.

- Primer. After drying the sealant, the roof surface is grounded using epoxy primer. The material is stirred by a low-speed mixer until the formation of a homogeneous mass is then added half the volume of water and stir again. A mixture is applied with a brush or painting roller.

- Reinforcement. After drying the primer, a layer of bitumen mastic is applied to the surface. Before it freezes, the construction bandage is stacked, and after the frozen - one more layer of mastic.

- The following layers are stacked by vapor insulation materials. Polyethylene or polypropylene films are often used in their quality. They are attached to the surface with the help of glue or fastening material.

- The heat-insulating materials are stacked on a layer of vapor insulation. As a rule, when they care, the roof is given the necessary slope.

- After laying the heat insulation, the screed from the cement-sand mixture is applied to it. Mount the screed is necessary so that the angle of the roof of the roof is preserved.

- The latter stroke will be the laying of waterproofing from bitumen or membrane materials. It is worth noting, the flat roof of TechnoNikol is one of the best on its operational qualities. Laying bitumen materials is conjugate with their heating open fire, so it is necessary to carry out such work with the fulfillment of fire safety requirements.