Before building a building, you need to consider the heating system. Earlier for this, furnaces were applied, today the setting of boilers is common.

Content

The correct blockage of the solid fuel boiler is the key to the uninterrupted operation of the system. Do this independently, the condition is not obligatory. If there is a desire to save, then this article is intended for you.

Stopping a solid fuel boiler heating

To avoid unforeseen situations and unnecessary expenses, it is necessary to determine in advance with which scheme of a solid fuel boiler will become the most optimal.

Solid fuel boiler strapping: basic tasks

1. Creating conditions for normal operation.

For the normal operation of the equipment, you should create a certain temperature of the coolant in the reverse line, which is regulated by the boiler manufacturer.

It is possible to ensure the balance of temperatures with the introduction of a small circuit into the strapping. According to it, the coolant will circulate, warming up to the desired parameters. Then he will head for a large loop and will transmit heat to heating devices.

2. Maintain the temperature of the coolant.

The binding dual circuit creates the possibility of thermoregulation when the device is operating in the stationary mode. The main advantage of boilers acting on solid fuel is:

- lack of complex automation;

- easy device.

The first to compensate for the first to be compensated for the scheme for which the cutting of a solid fuel boiler is created.

3. Protection of the boiler from overheating.

In the boilers operating on solid fuel, the dosage file feeding is not provided. At the same time, its burning should not be interrupted.

When the electricity is disconnected, forced circulation in the heating system stops the pump, which leads to overheating and damage to the boiler.

There are a number of methods that can be used to remove excessive heat, but the most effective is a blockage that includes an emergency scheme.

Thus, the installation of the strapping of a solid fuel boiler of heating allows:

- connect several contours with different operating temperatures;

- remove air from the system;

- create a safe operation of the equipment;

- provide on the system circulation of heated coolant.

Solid fuel boiler strapping scheme

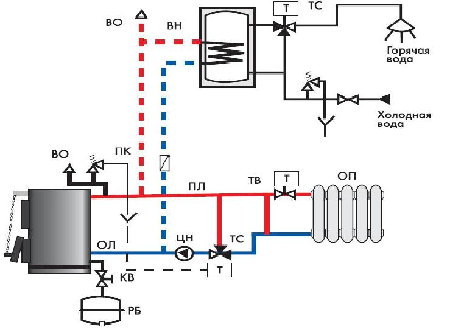

Photo of the strapping of a solid fuel boiler are presented below.

1. Gravitational system with an expansion membrane closed tank.

When installing such equipment, the system becomes closed, so you need to take care of installing additional devices:

- upset safety valve (will equalize pressure);

- automatic air vent (will drop excess air);

- manometer (with its help control).

2. Open-type gravitational system.

It is the easiest option. Such a design involves the presence of a natural circulation of the coolant. This ensures due to a certain location of the pipes, in which the heating elements are 0.5 m above the level of the boiler.

Notes:

- necessarily the presence of a non-cut contour;

- the membrane or open expansion tank will protect the system from exceeding the maximum pressure;

- the open-type expansion tank should be located on the highest point of the heating system.

3. Gravitational system with mounting a water tank on one of the branches of the system.

Provides a house with heating and hot water. The main disadvantage of such a system is uneven heating (the boiler operation should be regularly monitored) and the connection to electricity is necessary.

4. Cutting solid fuel boiler by polypropylene.

To establish such a system, it should be done so that the coolant is supplied to the contour of heating with polypropylene pipes not directly from the boiler, and from some buffer tank (heat accumulator, hydraulic capacitive separator).

Carrying out the strapping of solid fuel boiler Vaedarrus in this way, you will create an autonomous heating system that does not depend on the supply of electricity and gas supply.

5. Forced coolant circulation.

Provides the convenience of temperature control in the system. However, in addition to the pump that creates uniform and constant circulation in the water system, you need to install:

- expansion tank;

- safety valve;

- airlightener;

- thermostatic mixer;

- cap and thermostatic valve.

6. Cotelet strapping by the heatacumulator.

In this container, the coolant with a high temperature is accumulated. In the case of its disconnection, water consumption is carried out from the heat accumulator.

Advantages of installing such a system:

- the supply of water can be used in domestic needs;

- there is no need to continuously monitor equipment;

- the danger of explosion, overheating;

- the device increases the efficiency of the boiler operation.

Solid fuel boiler strapping: Features

1. It is necessary to carefully perform all connections.

2. The ideal option is a diagram with two contours - small and large.

3. The large outline is used to heat the water.

4. The strapping of the boiler operating on solid fuel should be carried out from non-combustible building materials.

5. Do not forget about emergency versions that can be performed as follows:

- the creation of 2-circuits with natural circulation operating on different sections of the system;

- installation of a gravitational spare contour;

- cold water supply from water supply.

4. When using several types of heating equipment in one system, the best will be the burden of solid fuel and electrocotel.

Cutting a solid fuel boiler with their own hands

1. We perform the installation of a boiler manifold, focusing on a special sticker located on it. Where stated otherwise, and the feed line.

2. We fix the boiler tube of 1.25 cm in diameter. In this case, the heating system has to be suitable tube 1 cm in diameter.

3. If you create a piping circuit alone, the side openings must be closed with plugs. In the future, they can be use to connect the expansion tank or an additional collector.

4. Install a three-way mixing valve at the input of the boiler manifold. So you will provide the ability to adjust the temperature.

5. We select a set to fix the circular pump. We pay attention to the height of the latter (13 or 18 cm).

6. Mount the circular pump on the reverse line. Switch it to the contour. If he is radiator, then the equipment is connected immediately to the collector, if low-temperature, then after a three-way unit.

7. After the circular pump, we mount the pressure control unit and the temperature, which consists of 2 valves with thermometers and the differential valve.

Thus, the blocking of the boiler operating on solid fuel is similar to the strapping of any other boiler. However, if you do not have certain skills and knowledge, it is better to use the services of specialists.

Solid fuel boiler strapping: video