Growing potatoes is very hard work. Its landing, emphasis and cleaning requires large physical exertion. Especially the problem is exacerbated if the landing area exceeds 15 acres. In order to at least simplify a job, you can automate this process. If the farm has a motoblock or mini-tractor, work can ease automatic potatoes and potatoes. Such specific equipment is purchased with a motor-block, but sometimes prices for it exceed the cost of the motor-block itself, making it not too accessible for a wide range of users. Exit from this situation can be the manufacture of these devices with your own hands. They are quite complicated, so for their production it is necessary to know the foundations of mechanics, have experience of welding and mechanical places. How to make potatoes and potatoes with your own hands - further in the article.

Content

Principle of operation and device potato

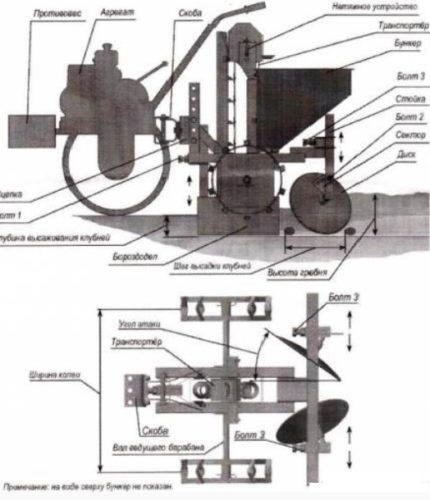

The potato melting is a trailer for the motoblock. The principle of its work is based on the automatic supply of planting material from the bunker to the furrow. Following the motoblock, thanks to the plow installed on the frame, the device makes the moon of the set depth. Then the chain conveyor, which rotates through the rotation of the wheels of the potatoes, the planting material is supplied from the hopper well. After that, the two discs installed in the tail part of the frame bury the well with ground potatoes.

The dimensions of the potatoes are selected individually depending on the power of the motoblock. Thanks to the exact selection of the distance between the supplies of the conveyor, you can achieve a uniform boarding of tubers throughout the row.

The main parts of the potatoes of the Motoblock made by their own hands:

- Frame. It establishes all the working elements of the unit. The frame is made in the form of welded metal structures from the profile pipe. This material has sufficient strength, while having a small weight. In the bow of the frame, a trailer is installed, which provides a clutch of the unit with a motoblock.

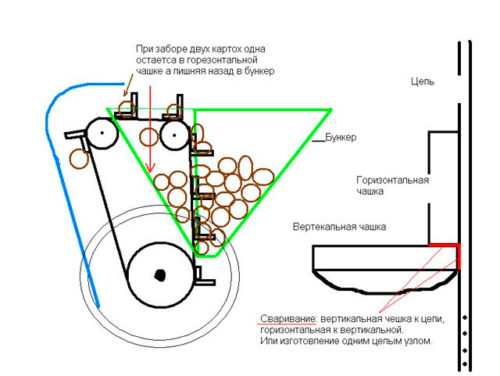

- Bunker. Designed to load the planting material into the unit. Performed in the form of an inverted pyramid. This form is needed so that the potatoes constantly face down. If this does not happen, then some bowls of the conveyor when moving will be empty, which will lead to an uneven landing. For the manufacture of the bunker uses a thin sheet metal.

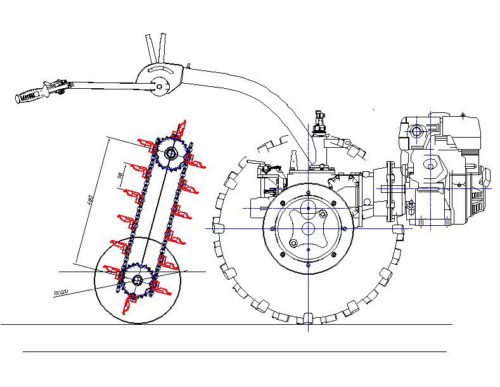

- Chain conveyor. It is performed from a motorcycle or cycling chain with a welded bowl on its surface. The conveyor drives the drive asterisk installed on the wheel shaft. From above connected with a stretch asterisk.

- Plow. Installed in front of the mechanism of planting material. His task is to produce the deepening, in which potatoes will be planted.

- Disk harrows. Installed at an angle to the axis of potatoes in the tail. They are needed to bury well with planted potatoes.

Making potatoes with their own hands

Make an independent potato mossella to the motoblock at home is quite difficult. Some operations (welding and turning works) will have to do in production conditions. Before starting work, it is better to make drawings of potatoes for a motoblock with their own hands. This will help calculate the amount of material and determine the most optimal sequence of work.

To produce this work, you will need:

- A sheet of steel thick up to 2 mm for welding of the bunker.

- Pipe Profile with a cross section of 25x25 mm for welding frame frame.

- Chain motorcycle or cycling.

- Two identical asterisks with a diameter of 80 mm.

- The axis of the wheel (will have to be pulled under the size of the bearing used and the inner planting diameter of the asterisk).

- Wheel hubs for mounting drive wheels.

- Cultivator discs.

- Borozdowel (plow). It is necessary to make it from a piece of durable sheet metal, since it will be high pressure on it.

Procedure for work:

- The first thing is welded a frame of construction, on which all working parts will be installed. It is welded from the profile pipe. Conveyor racks, spars are welded to the frame to give stiffness design. Also welded a hook for clutch with a motoblock.

- On the bottom, the fastening structures of the plow, disks, climb and the bearings housing are welded.

- Next is the assembly of the shaft. On the shaft with a key, the drive asterisk of the transport conveyor is attached and secured. The shaft itself is installed in the bearings. The wheel hub is mounted on its end.

- The next step is made of the conveyor bowl. They are made from thick wire Ø 6 mm in the form of a ring with a diameter of 60 mm (the average size of the planting tuber). A piece of wire is welded to the ring, making the bowl deepening.

- The finished bowl is welded to the attachment. The latter is welded to the links of the chain. Depending on the diameter of the drive asterisk, the wheels and the length of the chain can be experimed by determining the installation step of the conveyor bowl so that the distance between the planting tubers was from 25 to 30 cm.

- After the chain of the conveyor is ready, start the installation of idle (stretch) sprocket and pulling the potatoes made by their own hands. The principle of its work is the same as the principle of tensioning the circuit of the bicycle.

- Next is mounted bunker. It must be mounted in such a way that the working part of the conveyor passed through it and captured the planting material. In this case, the chain should not cling to the walls of the bunker, as this can lead to its destruction.

- After that, you need to install the chain. To turn it through the bunker hole, the chain must be disconnected. After that it connects and is installed on the workplace.

- Hosting side of the conveyor is closed with a chute from a thin galvanized. This is done so that potatoes do not fall in the wrong place.

- Next, drives are mounted. They are attached to special sectors that allow, if necessary, change the angle of attacks and an angle of inclination.

- The last step is the drive wheels.

Principle of operation and design of potatoes

The work of the potatoes is to lift the roots from the depth and separation of them from the tops and the soil. In the use of potatoes there are plays and cons. The most important of them is the quality of harvesting. Here is the main thing - to properly configure the aggregate. Otherwise, you can leave up to 20% root in the ground, and such losses will be able to reduce all the efforts made to "no".

Potatoes are different types that differ in both the principle of operation and the complexity of the design:

- Falcular type potatoes. The easiest type of device, which is characterized by ease of manufacture and use. Such a potatoes is a steel arrow, which at an angle enters the ground and raises the tubers together with the soil. In the rear of the boom, a fan of steel rods was installed, through which the soil is sieved, and the tubers are discarded to the sides.

- Vibration type potatoes. More complex designs. The principle of their work lies in the screening of tubers on a special vibration table. Due to this, the soil cohes down, and the potatoes itself laid out ribbon along the row. Vibrotol actuator is carried out from moving parts of the motoblock. Alone, such structures are rarely manufactured due to their complexity and the need for a wide range of mechanical assistance.

- Conveyor-drum type. The most complex aggregates. The principle of their action is as follows:

- A special device captures the soil with tubers and directs them to the conveyor.

- Last raises tubers from the ground and sends them to a rotating drum grill. There they are separated from the ground and fall into a special bin.

- The advantage of such a potatoes is that potatoes do not need to be collected from the row.

Production of felting-type potatoes do it yourself

The design of such a potatoes is the simplest and most often manufactured at home. To carry out this paper:

- Lap of cultivator. It is she who will be the most important part of the aggregate.

- Circle with a steel diameter of 8-10 mm for the manufacture of sifting veser.

- Steel sheet thickness 4-5 mm for the manufacture of a clutch with a cultivator and adjustment device. It is necessary to change the angle of an arrows attack.

- Bolts fasteners.

- Screed screw.

Procedure for work:

- To begin with, you need to fight steel rods to the crust of the cultivator lama. It is necessary to do this with a periodicity of 40-50 mm. The length of the fuel should be the same, respectively, if the rear edge of the arrow is at an angle, the length of the rod will be different - the farther from the center, the shorter.

- After that, the welded rods need to get up at an angle of 30 °.

- Next, two holes are made in the paw for fastening it to the bracket and the adjusting screed. Bracket and screed are welded to the hitch plate. Due to shortening or lengthening the paw screed will move forward-back, thereby changing the angle of attacks of potatoes.

- The last stage the potatoes is ground and painted.

When using it, it is important to monitor the state of the front edge. It must be well sharpened. Otherwise, the pressure on the arrow will be too high, which can damage the structure.

The parameters of potatoes are brewing depending on the type of soil treated. Than it is denser, the stronger should be a design.