A ribbon-sawing machine on a tree slowly accelerates and simplifies work with wood, and therefore it is simply indispensable in furniture manufacturing and at various enterprises of the woodworking industry. Some such a device can be useful for household needs. In this article we will tell about the types of such a mechanism and describe the process of its assembly with their own hands.

Content

Classification of band sawing machines

Band saws were developed for a long time, in the 19th century. Since then, the devices were modified and improved, and reached us at a more improved form. The difference and the main advantage of such a mechanism is the presence of a flexible annular saw, thanks to which you can make cuts of any form - direct and curvilinear. With the help of such a machine, you can make a variety of complex details, and the device easily copes not only with a tree, but also with metal, plastic, foam.

By way of location, band sawing machines are classified for such types:

- Vertical ribbon woods on wood. In large-sized mechanisms of the stationary type, the working part consists with a vertical saw, which moves during operation. In the tabletop ribbon windows, the tree did not move, and the table top with a wooden part.

- Horizontal woodcuts on wood - powerful and large-sized devices, with which you can saw large trunks, long solid logs, metal and especially solid wood.

Depending on the degree of automation, the designs are:

- Fully automatic. Such machines can be found in industrial production.

- Semi-automatic - they are more often used for the manufacture of furniture. In these mechanisms, saws and vice work.

- Manual - to work with such tape-saw wood machines, the material must be applied manually. The process of sawing wood is also managed by a person. A similar belting machine on a tree can be considered a domestic, and it is found primarily in private workshops.

Machines are classified and tape type:

- Mechanisms with narrow saws whose width ranges from 2 to 6 cm, most often used in small shops or are used by amateurs furniture. Narrow saws can not be sharpened, after complete wear, they are replaced with new ones.

- Devices with wide saws with a thickness of 10 to 30 cm are considered more productive. Such equipment is advisable to use for industrial manufacture of furniture or logging. Saws with a wide web can easily cope with solid wood and with trunks thick up to 1 m. Wide saws can be hosted if necessary.

If you rely on the size and power of machines, they can be divided into such types:

- Carpentry - designed to perform minor work in small carpentry workshops.

- Dividing - apply in the production of furniture. They divide the logs on the layers.

- Breeding - such machines are distinguished by high power and large dimensions. You can meet them at the enterprises of the sawmill industry.

Technical parameters of band sawing machines

If you decide to buy a ready-made ribbon machine, then, depending on the conditions of its future use, the important technical specifications should be taken into account:

- Power - this parameter determines whether the unit can be used in household or for industrial purposes. For household machines, power will vary within 500-750 W, and for industrial, this parameter can reach 3 kW.

- The network voltage - also depends on the conditions of use of the mechanism. The household machine will operate from 220 V, industrial - from 380 V.

- The depth of the cut is the indicator of the boards of which thickness is able to cope the unit. The depth of the reise ranges from 15 cm to 1 m.

- The width of the saw is a parameter equal to the distance between the rack and saw. The minimum width of the saw is 35 cm.

- The speed of cutting - the smoothness of the cut depends on it. This value varies within 200-1250 m / min. The faster the machine splits the log, the cleaner it turns out the cut.

- An important technical characteristics should also include the length of the saw, the weight of the unit and the size of the desktop.

Features of the saw blade

The saw blade for a tree ribbon machine also has certain characteristics:

- Production material. As a rule, saws for such mechanisms produce from steel with high flexibility. Steel passes a double hardening, which allows the canvas for a long time not to fasten even when the solid wood is cut. Saws made of soft alloys can be sharpened and even welded from fragments in case of need, but the canvas with solid teeth after wear are completely changed.

- The size of the teeth is an important parameter that determines with which materials can cope with a ribbon machine. For example, Phaneur, chipboard, MDF, solid rocks are sawed with small teeth, soft rocks need a bigger teeth. From this indicator also depends the smoothness of the sleeves - the small teeth do it cleaned cleaner than large ones.

- The shape of the teeth is another characteristic to pay attention to. Most of the aggregates have a standard shape teeth, they are universal and can saw almost any materials. The teeth are also bent under the sharp angle - such saws cope with dense tree rocks. Teeth with large gaps are best working with solid trunks.

- The saw blade is distinguished by a certain divorce of the teeth. This parameter is needed so that wood in the process did not clamp the saw from two sides, and the furrow itself was wide enough. The divorce of the teeth helps turn the item and make curvilinear cut. Divorce is standard, in which the teeth are tilted in different directions. Expanding divorce - when two teeth are inclined in opposite sides, and one reprehensive tooth is placed between them. The extender divorce allows you to make curvilinear cut. The wavy divorce means that the teeth bent into each side like the waves - such a canvas is suitable for working with thin materials.

- The ribbon width can range from 3 to 200 mm. Wide saws are used for longitudinal separation of boards, narrow - for transverse.

Technique work with beltopile machines

The first thing you need to remember when working with similar aggregates is observance of safety. The process of using the machine is as follows:

- Wooden item is put on the pipe and fix well. Fixation is necessary in order that the work surface does not vibrate, and the sleep turned out to be even.

- Then the workpiece is divided by the guide line or using the moved stop.

- For curvilinear cutting on a wooden part you need to pre-apply marking. Instead, you can use special devices for feeding and fixing the wooden element.

Creating a ribbon tree on wood with your own hands

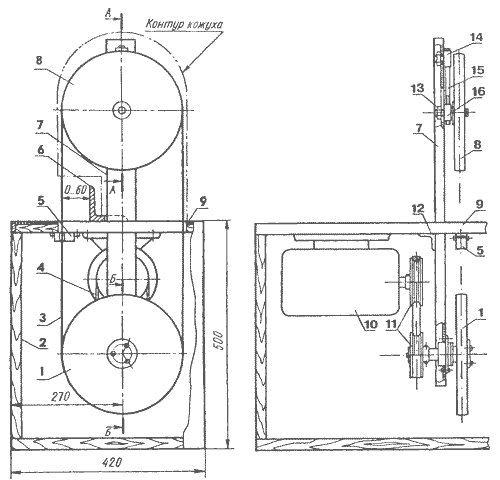

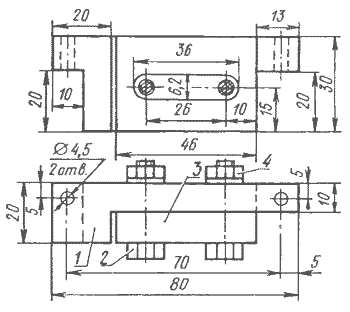

It must be said that the finished unit is quite expensive, and some prefer to gather it personally. To make a ribbon tree on a tree with your own hands, take a look at its drawing, submitted below:

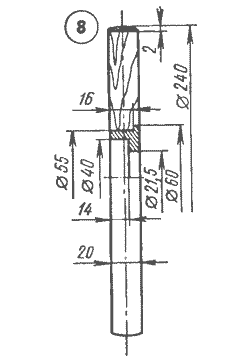

Description of the design details of the mechanism is given in the table:

A homemade ribbon machine on a tree is made in this way:

- To make the aggregate with your own hands, you must first make a schematic drawing of both the machine itself and its individual nodes. The scheme specified above will help you, only in the drawing you need to specify the individual dimensive wall dimensions.

- The next step from the profile pipe is booed by a frame of the table. Standard dimensions are equal to 42x72 cm.

- Then from plywood make the tabletop itself. Suitable plywood sheet thickness - 20 mm. Table top material must be saved with textolite.

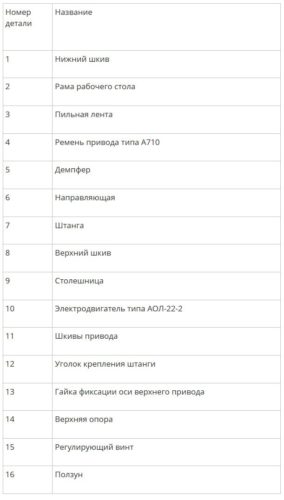

- The next stage on the desktop is mounted carrier bar. For its manufacture, the channel number 8 is 68 cm long. The bar is installed on a transverse profile and a corner that weld to the frame.

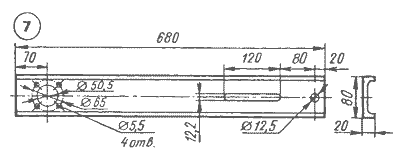

- Then, from the same exactly plywood, as the countertop, make pulleys - the bottom and top. Pulleys need to salary rubber on top.

- Wooden surfaces are coated with epoxy resin and grind. The same resin is glued with a duraluminum sleeve, which before it needs to be equipped with a gap for bearing 60203.

- The pulley located below is fixed on the axis of 30xgs using 3 screws. Then the axis is mounted in a tan on 2 ball bearings, and the pump itself is attached at the bottom of the rod.

- The remote sleeve pulley belt drive is attached to the second end of the axis.

- Then the engine is installed on the desktop. The engine is connected to the driving pulley. Make sure that the pulleys are on the same level and were reported by the belt.

- Then at the top of the rods install support with an adjusting screw. The upper pulley is mounted on the axis with the slider. The resulting design is fixed on the rod, after which the tape pulleys are located at one level.

- Where the saw passes through the worktop, the damper is mounted. It is made of textolite, and the diameter of the damper can be seen below:

- The next step is the saw blade must be hidden, and for this you need to prepare a special casing. It is made of steel, after which it is fixed on the rod and surface of the table.

- To bring the entire mechanism in motion, you need to make a switch. It is located on the frame, equipped with a wire with a fork, put the wiring to the engine.