If you need to produce high-precision parts of the permanent connection of metal products and constructions, shapes which do not undergo changes during welding, laser welding is best suited for this purpose. The main issues that arise in front of those who are planning for the first time to use laser welding in practice, sounds like this: "What kind of equipment is used for laser welding? What settings must be put on the welding machine for welding of metals and steel? Is it possible to produce laser welding with his own hands, is not dangerous if it is? "

Content

laser welding technique

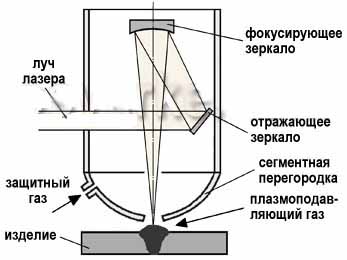

The principle of laser welding is based on the fact that during laser exposure to metal joints and steel products occurs absorption of energy, heating of the metal, melting it and the interaction at the atomic level. Then the metal crystallizes and there is a strong bond - welded seam. directing mirrors used to focus the laser beam energy. Coherent laser radiation having a minimum divergence, acts on the metal portions accurately calculated at the point of coupling necessary at large distances without loss of quality.

With laser welding, penetration into the material does not exceed 2 mm. At the location of the laser focus, the metal heats up and a cylindrical hole is formed, which is filled with ionized gas. It is an effective absorber - capture of 95% of the laser energy. Such a hole is called a keyhole, and the temperature in it can reach 25 thousand C, which ensures the highest degree of laser welding efficiency with a minimum welding spot. Accordingly, the stresses of the material and its deformation during the welding process are minimal. The speed of laser welding is up to several meters per minute or more, that is, it is the best kind of welding.

Types of lasers used

By type of active medium, laser installations are divided into solid-state and gas.

Solid-state

The active medium in a solid-state laser is a rod of pink ruby \u200b\u200b(aluminum oxide with chromium ion impurities). Chrome ions during irradiation are heated and transferred to the excitation state, then giving out stored energy. The ends of the ribbon rod are coated with reflective substance (silver), forming a translucent and transparent mirror, from which chromium ions are reflected and circulated on the helix around the ruby \u200b\u200brod, exciting the following ions and forming avalanche-shaped process. An energy explosion occurs, which is sent by a parallel beam through the translucent mirror and focuses the lens to the welding point. Output power of lasers of this type - 10 7 W, the cross section of the beam is 1 cm.

The disadvantage of the solid-state laser when operating in a pulse mode is low efficiency - from 0.01 to 1%. A higher percentage of efficiency is achieved when working in continuous mode of lasers with other varieties of rods.

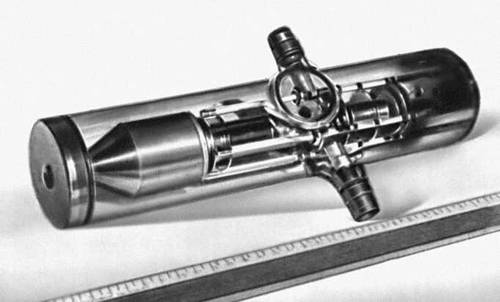

Gas

The efficiency of the efficiency and power of gas lasers is a significant advantage compared to solid-state. The design of such lasers is a gas-filled tube, from two sides bounded by translucent and opaque parallel mirrors. Electrodes were introduced into the tube, under the influence of the discharge between which there are rapid electrons, exciting gas molecules. When they return to a stable state, the formation of light quanta, which focus on the place of welding occurs. Gas lasers work both in pulse mode and in continuous.

Laser welding of metals

Laser welding of large thickness metals is made with deep penetration, that is, with the formation of the steamed channel, which is radically different from the welding of small thicknesses. Parameters affecting the depth of the propagation:

- radiation power;

- welding speed;

- characteristics of the focusing system;

- fashion composition;

- ray divergence;

- density distribution in the cross section of the beam.

Power selection is carried out according to the following principle: the minimum digit should provide a digital inquallation, and at the maximum indicator, defects should not appear during welding, that is, the seam should be of good quality. The focus diameter of the welding stain is 0.5-1.0 mm, otherwise the adhesion efficiency falls. High performance and necessary welding parameters provides a speed of 25-30 mm / s.

Laser welding Steel

Low-carbon and low-carbon low-alloyed steel, which have excellent weldability, obtained the greatest distribution in the manufacture of welded structures. The recommended laser welding mode, which ensures the absence of cracks - high-speed (30-40 mm / s). Power from 3 to 5 kW, focal length from 12 to 20 cm, focus plug - 1.5 mm.

Laser welding requires preliminary preparation of the edge of steel structures - cleaning from scale, rust and removal of moisture. The assembly for welding is made with the highest possible precision fitting parts and parts of the structure. A gelium or a mixture with argon is used as a protective gas.

Manual laser welding

Recently, compact welding systems operating in manual welding mode have been developed, with programmable settings. Using such equipment can be made:

- point welding "Jack";

- laser surfacing and repair of molds;

- processing of parts and elements of medical equipment;

- repair of jewelry;

- superficial hardening of materials;

- welding in microelectronics.

Advantages of laser welding

Among all the variety of welding technologies, laser allocate the following features:

- high performance and speed process;

- thermal exposure zone bounded by a small laser focus diameter;

- ease of installation management and their fast reprogramming;

- environmental friendliness;

- high quality, reliable and ultra-compound metals;

- the possibility of clutch in hard-to-reach places.

The video presents laser welding performed on various equipment - a fully automated German complex and a manual programmable system.

There were those times when the laser was only a laboratory device.

Currently, the laser was widely distributed in all branches of the economy. Laser can even buy on the street in the newspaper kiosk.

However, do not everyone know that the laser can be made independently at home. Moreover, you can make such a powerful laser that his ray will even burn wood.

How to make a laser yourself, read on the pages of the site http://pulslaser.usite.pro.