Putclone oil-adhesive is mainly used for construction work during repairs. This material is not too expensive and sufficiently convenient to use.

Content

Before the start of processing work, the surfaces of walls and ceilings is prepared. They must become smooth and this is an important part of the preparation. The quality of it affects the service life of the subsequent finish and the final appearance of the premises. Special putty compositions offered by the market today will help align all surfaces and process cracks.

Putclone oil glue

Unprofessional masters it is difficult to determine the choice of one or another composition for the walls. For independent finishing work, it is better to choose oil glue putty. She plastic, durable and just work with it. This material has both a number of advantages and its drawbacks.

Advantages of oil glue spacure

- There are ready-made compositions on sale. Before applying, they are not required to prejudice. It greatly simplifies work.

- Simple preparation. Before direct application, the finishing mass is mixed, but even this is not mandatory.

- Low cost. This allows the use of oil adhesive putty to process large surfaces. The material is fairly profitable to use with mass construction work. Financial costs in this case will be minimal.

- Good grip with many surfaces.

- By 1 square. The surface of the surface will require about 1 kg of the mixture.

- Easy application due to plasticity. This property allows surface covering enough quickly.

- Fast drying. No need to wait long before applying the subsequent layers. Just a few hours.

- Durability - putty will last long on the surfaces of the walls or ceilings.

- Ecology - there are no harmful components that can cause allergic reactions in humans or cause harm to the environment.

- Thanks to this amount of positive moments, it is very profitable to use this type of putty.

Disadvantages of oil-adhesive putty

- Low strength with respect to mechanical effects.

- Instability to moisture.

- This type of finishing materials is used in the case of use for final lining of oil compositions. With other compositions, it is difficult to compatible.

- Some species of oil-type putty are produced with the addition of technical oils. The danger of this type of material in its minor toxicity. After surface treatment, the compositions of the premises must be carried out to avoid the occurrence of allergic reactions and health problems.

- Low shelf life. In the case of long-term storage, the glue spacing over time ceases to be plastic, and also loses some other properties. After 1 year from the date of manufacture, putty becomes unsuitable for use in principle.

- After storing the material in cold rooms and its freezing, the composition becomes unsuitable for use. It is better to purchase a new packaging than in vain spend time on useless work, which will not bring due results.

- Due to the described disadvantages, the use of putty of this type is extremely limited. It is not suitable for finishing surfaces, which will continue to be subject to regular mechanical effects, as well as with high levels of humidity and for outdoor buildings.

- It is important to observe all the conditions of application. According to the rules, the glue spacing is applied at a temperature of +15 ° C. The most optimal temperature regime is 20 - 22 ° C. The value of humidity cannot exceed 70%. Under such conditions, the flaws will not be expressed, and the work will look at the level.

Oil adhesive putty: composition

- This type of putty is a composition having a type of homogeneous type. Material This pasty and the basis of its manufacture is the binders of the components, pigments and substances for extracting the surface. This mass has a density thickness. It contains not so many components.

- Composition:

- water;

- hardeners;

- olife;

- fillers (crushed chalk);

- acrylates;

- pigments for coloring;

- plasticizers.

- Plasticizers attach additional properties with glue putty. Thanks to them there are such types of finishing formulations as:

- moisture-resistant;

- fireproof;

- explosion-proof.

- Coloring pigments cause existence of putty with elevated whiteness.

- Some manufacturers add a few more substances into the composition. Among them:

- pigments;

- additives;

- antiseptic type substance;

- thickeners.

Putty oil glue: Specifications

This type of facing is used during interior finishing works. Among them, leveling surfaces before applying the enamel or oil paint of the following type:

- wooden

- plastered

- concrete.

The oil-glue composition is characterized by its characteristics from all other materials for plastering. Consider the main of them.

- Fitness. The composition can be used from 6 months to 1 year. After the end of this period, the mixture will not effectively apply. The composition will lose all properties, and the putty will have a kind of crumbs.

- Density. There are no extraneous additional substances in the mixture, its composition is homogeneous and has a type of paste.

- Drying. The duration of complete fixing depends on the layer. Separate applying dries up to 4 hours, and finishing drying will require 24 hours, no more.

- Binder - Olife. This type of facing is made on the basis of this oily substance, which ensures most properties of the mixture.

- Storage. The putty is kept in a tightly clogged vessel. Minimum storage room temperature - 0 ° C. Negative temperature negatively affects weight properties.

- Consumption - per 1 square. m need no more than 1.5 kg. Minimum amount - 0.8 kg.

- Thickness. Each layer in depth is no more than 2 mm.

Decorative putty do it yourself

Decorative cladding with your own hands can be carried out for:

- Aligning different planes in front of their coloring.

- Wall processing / ceilings for final finishes.

- Elimination of flaps of equalized planes.

- Mascaze cracks.

- Repair of various furniture and other details of the interior.

Putty oil glue universal

- Universal types of mixtures are designed to carry out finishing works in rooms with optimal levels of humidity. They are applied to almost all types of planes: bricks, plastered, concrete, covered and varnished-covered.

- Their composition is immediately applied on the surface without preparing. The consumption of composition can be up to 1.7 kg per 1 sq.m.

- The putty can be the following types:

- frost-resistant;

- non-desarmed;

- transfer temperature fluctuations.

- It is necessary to prepare before it is applied to the surface: to process ground areas, remove dirt, spots from oils and other dirt types. Otherwise, the final result can be unsatisfactory, the composition does not clutch with the surfaces or will not have a presentable appearance.

Pluckle Oil Adhesive Tex Universal

- Products of this manufacturer are in great demand. Puttack "Tex" The wagon is well applied to different surfaces and stealing frost. No difficulties arise when it is grinding, besides this, such a coating as a result forms a sufficiently durable surface.

- Apply such a putty to cover the surfaces of the plasterboard, plastered, concrete, metal and wooden. It is suitable for aligning surfaces in dry rooms.

- This material is ideal for the color of the enamel, dispersion, as well as oil paints.

- The average consumption of material is 0.7 kg per 1 sq.m.

- Each of the layers dries up to 4 hours.

- The suitability of the material is up to 2 years.

Oil adhesive putty on wood

- The finishing of the wooden surfaces with putty makes the surface smaller, removes small cracks and roughness. The layer of such material will protect the tree from negative external influences and harmful insects.

- For the processing of wood planes, the choice in favor of such a composition is the most optimal. It is prepared not only by the manufacturing method, but also manual. It is suitable for facing the external and internal surfaces from the tree.

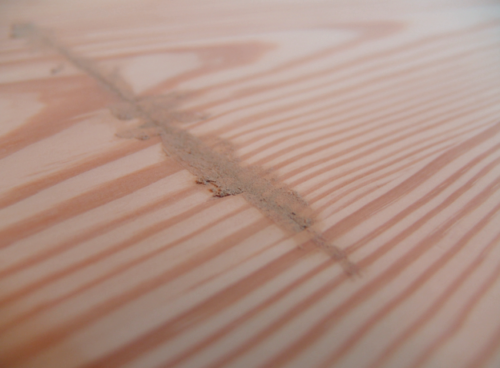

- Oil adhesive mass for wood decoration well enclosures with a surface that is subjected to pre-primer.

- After drying, the layer becomes solid, there are no cracks on it. The putty does not crumble, so it is convenient to grind it. For alignment, you can choose both dry and wet method.

- Application of putty on a wooden surface is carried out by a spatula or sprayer.

Putty do it yourself: instruction

The spacure is applied strictly in a ventilated room. In the hands there must be gloves to avoid the occurrence of skin lesions. Nearby is not allowed for sources of fire.

Stage 1: Preparation of surfaces

- Walls that will be treated must be carefully examined. All cracks need to be seen. The elimination of all surface defects are carried out at mandatory, otherwise the composition may not be returned.

- After that, the grinding of the walls and the ceiling is made. To do this, you can apply Olif or Latex. They are bred with water in proportion 6: 1. If you do not conduct it, some problems may arise during the applying of putty.

- Next, the packaging is opened with the composition. It is well mixed. In the case of too dense consistency, you can additionally dilute with olifa. Add the substance must be carefully so as not to spoil the mass. Too liquid putty is not suitable for finishing surfaces.

- Oil adhesive plaster is better enclosed with in advance shtown surfaces. They should be well dried. Otherwise, the facing layer does not sit down, and all work can become in vain.

- Surfaces need to be deguted, clean from dirt, sand metal and wood. The quality of the last coating layer depends on these actions. If the planes remain dirt, it can interfere with putty. On such sections of surfaces, the composition may not be applied.

- When processing concrete walls, surface preparation can not be done. But experts recommend processing and their primer with the property of deep penetration.

Stage 2: Application

- For applying putty, no wide knowledge in this area is not needed. You will need only a few tools and instructions. With this case, any summer house will easily cope, accustomed to all do it yourself.

- For applying, a spatula will be required. You can take a metal or rubber tool.

- Oil mass must be mixed. During this process, there is a uniform distribution of olifes around the composition. It is especially important to mix the mixture thoroughly if the putty is worth a long time.

- Application is performed using a spatula. It is best to take an unintent tool. The coating must be slightly rubbed into the surface to close the remaining cracks of the shallow sizes.

- Apply the facing is needed at least 2 layers. The minimum permissible room temperature during operation - 10 C. At lower temperatures, the putty will start to lose its properties.

- The finishing layer is applied not earlier than the day after applying the previous one. Otherwise, traces of oil may appear on the surface.

- For its application, the drill will be required, the grater is a construction and paper emery.

- With the help of a drill with a nozzle "Mixer", the composition is mixed. Then applied. The sandpaper will allow you to disperse the applied layer, and with the help of a grater you can create uncomplicated patterns.

Putty oil glue: Price

The cost of putty depends on its type, manufacturer and composition. The more additives, the higher the price. On starting putty, some prices, and on the finish line - others. Putty for interior decoration and for external also have different costs.

Universal material for cladding from the popular "Tex" manufacturer has the cost of 150 rubles and higher. Other manufacturers exhibit higher prices for their products.

For all the work, you will have to pay more in the case of contacting the specialists. With independent execution of putty, expenses will be minimal.