Most of the private territories protect the hedge, the key part of which is the wicket. Often also set the gates swing metal with a wicket. Moreover, they perform not only a functional, but also a decorative task. Therefore, when planning the fence of its site, it is necessary to pay special attention to the gates and gates. The appearance and design of these elements are largely dependent on which fence will be installed. Therefore, most often the gate and gate are performed from the material from which the fence itself is made.

Content

Types and characteristics of wickets

There are several requirements that need to be performed when you mount the wicket or gate. First of all, these designs must provide the necessary level of security. Like the fence and sash, you need to build enough strong. In addition, the gate and wickets should be conveniently opened and at the same time provide a free passage. To do this, it is required to correctly calculate the dimensions of the design and choose the appropriate fittings.

It should also be said that it is necessary to properly provide for individual shut-off elements, i.e. A reliable castle must be installed. Especially if there is something valuable on the territory. It is equally important that the material from which the gate is made is quite wear-resistant and durable. At the same time, the wicket must look good. After all, the entrance to your site can be said is his "face" and "business card." Therefore, its appearance should be quite attractive. Therefore, often prices for the gate or gate are the same, or even more than the entire fence.

Consider what kind of wickets are:

- Wooden. Such wickets are usually put in the case when the fence is similar to the tree. This is done so that they harmonize with each other. At the same time, the support pillars are usually made from the skyr-rounded logs or BRUSEV, the ribs of which are steps. The thickness of the support should be such that the required rigidity of the system is ensured. The canvas is made of 25-40 mm thick boards, which depends on the design features of the wicket and hedge standing nearby. Usually the lower the fence, the topics of a lesser thickness use. For wooden wickets, wrought metal loops will look at the best possible wickets. They perfectly fit into the overall style of fence. Wood wickets are suitable not only for wooden fences, but also for fences from any other natural material (for example, bricks, stone).

- Metal wickets. These are mainly welded and wrought structures. These options should be viewed together, because They are very similar to each other. They are usually put in the hedge, made of the grid, in modular or lattice fences, as well as in forged fences. Most often, similar wickets are made of a round or profile tube, angle or reinforcement rods. Most models have a frame design. At the same time, their perimeter limits the rigid basis. Inside the frame is less durable and lightweight material (pipe or arm of reinforcement). Such wickets are quite heavy. Moreover, their significant mass falls on powerful fittings. Such elements, in particular, include durable and large steel hinges that can be made personally or purchased in the finished form.

- Plastic. Such wickets are most often used in cases where fences are made of PVC. As a support for such structures, the reinforced metal profile tubes made of polymeric materials are suitable. At the same time, they have a greater thickness of the walls than the pipes that are used in the construction of the fence. Such wickets are assembled almost by the same scheme as the hedge themselves. In this case, due to the fact that they carry the bulk, massive horizontal supports can be used. To hire such sash, special reliable fittings will be required. Due to the low weight of such wickets, the elements of the accessories are made of rather thin metal.

Main parts of metal wicket for giving

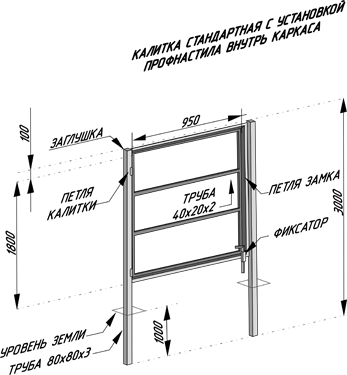

According to the drawings of metal wickets, their design has four main details: frame,

- trim,

- sheds,

- latch.

The frame is, in fact, the base of the wicket and the gate that is performed from the metal profile. For this, there are mainly used corners, pipes and chawliers. The base is covered with trim. For its manufacture, various materials are used. Canopies are details, with which the design of the metal wicket is attached to the carrier part of the fence, which makes it functional. Finally, the latch is part of which can be locked the door or limit its performance. Whatever the material is not used for the trim, the framework will be in the design of the wicket in any case. For the trim, it is recommended to use metal corners and pipes.

Before making a metal wicket and install it in place, you need to decide on some important moments:

- The bottom of the design should be slightly higher than the support pillars. So the wicket will not be thrown about the Earth.

- The top of the design should be slightly lower or level with the boundary of the top of the fence, if the gate is lower, they will look not so attractive.

- You also need to decide on width width. It should be the same as the width of the opening, minus 25-35 mm, which depends on the method of fastening the wicket to the fence.

In order to make the vertical racks for the base of the wicket, you will need several metal profiles - two horizontal profiles and another extra. The latter length is calculated by subtracting the two-width of the profile from the frame width. The profile will be installed horizontally, in the middle of the design. At the same time, it should provide additional stiffness.

Installation of metal gates and wickets

Installation of columns

Poles are the main carrier part that holds the entire wicket design. Their length should be larger on 1 m overall design. This is enough to ensure that they can be securely burst into the ground. The installation begins with the fact that with the help of a bera, two wells are made. Their depth should be about 0.5-0.8 m, and the distance between them is about 1 m.

Poles are inserted into the finished wells and with the help of sledgehamps are ride another 0.3 m. After that, the support must be aligned vertically using a level. After that, they can be poured concrete. So that the poles are tougher, in the upper part they should be welded with a transverse profile.

The process of assembling the carcass

The framework of the frame assembly is performed in the following sequence:

- First there are 4 details of the profile that create the main perimeter.

- After that, the details of the jack are welded. It is important that all elements lie in the same plane. When fastening all parts, you need to check the diagonals of the rectangular shape of the frame to ensure that the design is in the end turned out to be smooth.

- Next, with the help of a grinder and a special nozzle for cleaning the metal of welded seams. As a result, a fairly flat surface should be turned out, without visible traces of welding.

- Additional profile welding is carried out horizontally in the middle. If the design is made from the profiled sheet or it is planned to sew it with a tree and at the same time the corner is used as a material, the additional profile must be in the form of a plate. If metal pipes are used, then the additional profile is recommended to make a cylindrical shape.

- After that, it is necessary to clean the welds. To finish the installation of metal wicket with your own hands, you should still attach a canopy, a latch, and then the design must be primed and painted.

Sheds and latch

Depending on the design features, the canopies may consist of 2 or 3 parts. One is attached to the carrier pillars, the second to the door, and the third one is used as a fastening element. Next, the wicket is squeezed by a suitable lightweight material. It is allowed to be attached without the use of additional details.

The wicket from the professional flooring has quite a big weight. For this reason, there may be insufficiently easy mounting of canopies. Usually, two additional profiles are added to the base of the canopy. In addition, additional planks are used to fasten the canopies along the entire length of the additional profile. In that case, if the reference pole is made of brick and simply impossible to welcome the canopy, you need to insert mortgage parts into the laying or install the iron slotting box, and then cast it to it.

As for the latch, any suitable designs can be used here. For example, it can be a strong metal plate protruding beyond the door. She usually keeps behind the support pillar. It may also be a castle, different parts of which are installed in the post and on the door. As a latch, a chain is usually used, which is attached to the frame and on the support post.

It is worth saying that the canopies and the base in the design of metal wicket are the most important parts that should be carried out strictly according to the technology. The remaining elements can be mounted arbitrary ways.

Cleaning gate

For the trim, you can use almost any suitable materials. If you need a deaf door, then a solid metal sheet is used most often, a thickness of 2-4 mm, which is cut according to the perimeter of the frame. After that it is superimposed and attached with welding. In addition, it is recommended to additionally strengthen the tricks. Do not use too thick sheets.

As a sheat, the edged board is often used, which is well combined with the corner base. The thickness of the boards must coincide with the width of the regiment of the corner. The boards are inserted into the base, and are attached to the corners with the help of screws. They are also attached to an additional profile.

For writing, a chain grid is still used. This material is more suitable for plating simple wickets and metal gates with a gate at the cottage. For this, a piece of the required size is cut, after which it is stretched and attached by self-drawing with wide hats.

The gate can be seized with a profiled sheet. It is very well harmonized with the corner base. For the trim first cuts out a sheet of the appropriate size, after which it is inserted into the corners. To the frame of the sheet is attached with rivets.

Decoration of gate

To make a wicket more attractive, on its outer side usually weld various wrought elements that can be easily purchased in many building stores. Today, there is a fairly large selection of such products. Therefore, everyone should choose something suitable for themselves. You can also do something with your own hands. The main thing here is your fantasy and desire.