In the conditions of constantly growing prices for energy resources, the energy efficiency of the residential building is one of the most important parameters of its service. Even the old building can be upgraded, thereby reducing the costs of its heating in winter or air conditioning in the summer. Reducing the thermal conductivity of all structural elements of the house will keep the comfortable temperature inside it, not carrying particularly high costs. The largest heat loss house carries through the roof, windows and walls. That is why the process of improving its energy efficiency must be comprehensive and include work on all areas. You can not replace only the windows in the house and hope for a good result.

Content

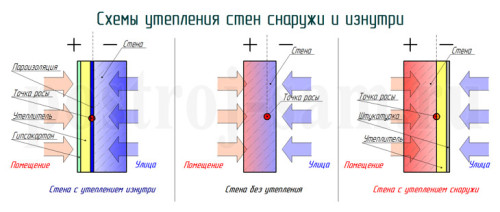

One of the most important areas of work on the modernization of the house is the insulation of the walls. They have the largest surface area, so they need to pay special attention. At the frequently asked question that it is better - to warm the walls outside or from the inside, heating engineering specialists are definitely answered: and there, and there. Only in this case can be achieved by the desired result.

Highlights of insulation of foam

At the moment there are two main options for external wall insulation:

- Ventilated facade. This facade is a system that consists of several layers: the layer of the facing material and the insulation layer. The advantage of this type of insulation is that there is a small gap between the insulation and cladding, which circulates air. Due to this, condensate does not accumulate on the surface of the insulation, which increases its service life. Application as a facing material of aluminum structures, granite blocks, professional flooring or plastic panels, which are installed on the metal frame, extends the service life without repairing the entire system. Such cladding is only necessary to wash from dust and it will look like a new one. Thanks to the arrangement of the frame, the ventilated facade is mounted on any surface, while the insulation of the wooden walls of the foam is made problematic. The disadvantage of ventilated facades is definitely its price that does not allow it to use for a wide range of houses.

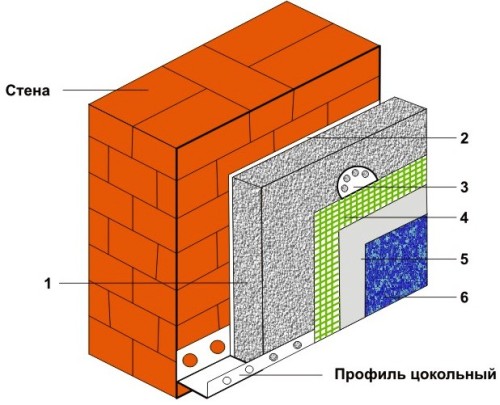

- Seamless method. With this method of insulation, the insulation is glued directly to the surface of the wall, and then plastered.

About how to insulate the house seamless method - further.

Materials for seamless insulation

For such a type of work on the market there is a large number of different building materials for both insulation and the external decoration of the insulation.

For the immediate insulation of the walls of the house, two types of materials are most often used:

- Plates from mineral wool. This is a pretty good insulation. His dignity is excellent thermal insulation properties, as well as fire safety. Compared to polystyrene foam slabs from mineral wool have quite large weight, so require the use of fasteners in large quantities. There are several varieties of basalt plates. Flexible have a soft structure and chaotic-located fibers of the mineral substance. They are used in systems of bonded heat insulation. In the lamella stoves are perpendicular to the plates surface. They have a smaller size and more convenient in the installation. Due to the fact that these plates are better adjacent to the surface of the wall, when they are installed, it is not necessary to apply a dowel, it is enough just to glue them to the wall and consolidate only the angular sections. Compared to polystyrene fiber on the surface of basalt plates it is more convenient to apply plaster. However, it is worth noting that the cost of such insulation is quite high.

- Polystyrene foam or foam. This is the most popular and most affordable insulation. The low cost of insulation of the walls of the foam made it the leader among insulation. Although he loses mineral wool in terms of vapor permeability and fire safety, as well as at the expense of low density - in sound insulation, but has excellent moisture resistance, does not require a large amount of fasteners and adhesive compositions. Basically, 2 classes of PSB-C-25 polystyrene or PSB-C-35 are used for insulation, which are distinguished by their density. The thickness of the foam for the insulation of the walls, depending on the purpose, varies from 5 to 20 mm. For the inner insulation of walls of walls, the plates are used by the slabs of a small thickness. Recently, a perforated polystyrene foam has appeared on the market, which is characterized by better vapor permeability.

One of the species of polystyrene foam is polyfasad. It is a two-layer plate, which is covered with a layer of concrete, imitating tiles or decorative stone. This protective layer allows you to do without plastering the surface of the insulation, which significantly speeds up the installation process. Thanks to the coverage, the service life of plates without facing (plaster, painting) increases, and the appearance they have more attractive. The insulation of the walls of the wooden house with foam is rarely spent, it is better to use a ventilated facade.

It is worth noting that other materials such as OSB plates, stoves made of corks, extruded polystyrene foam, polysclo, etc. are used for external seamless insulation. However, they are used only in isolated cases and they did not receive widespread.

Wall insulation with a foam with her own hands

Preparation of material

Consider the technology of insulation of walls by foam outside. With certain construction skills, all work can be performed independently. Before starting the installation, it is necessary to take care of the presence of the required material. So, it will take for work:

- Sheet polystyrene foam. Knowing the size of the walls, you can freely calculate the need for insulation. The thickest will be the thickness, the better heat insulation it will provide. Before buying this material, you should immediately take care of the place of its storage. The fact is that the polystyrene foam is poorly tolerates the impact of direct sunlight, so it should be stored in a darkened place. Buy plates needed with a 10% margin from the required area to re-ride it.

- Glue for foam. For glue insulation, special polymer compositions are used. Ordinary dry mixes may not come up, as they will have to work in a sharp change of temperature and high humidity. The amount of the mixture must be calculated depending on its flow (indicated by the manufacturer on 1 m 2 Surfaces) and insulation area.

- Dowels. For fastening the plates to the wall surface, the dowels of special shapes are used, the so-called "umbrellas" or "fungi". They have a hat with a large area, which allows them to reliably hold the leaf on the wall surface. The length of the dowel is selected depending on the thickness of the insulation. It should be inside the wall at least 50 mm.

- Reinforcing grid. It is superimposed on the surface of the foam for a better clutch of plaster. The grid area is equal to the dimensions of the insulation.

- Plaster. Be sure to use mixtures for outdoor work. Otherwise, over time she collapses.

- Primer. Designed for better adhesion plaster with the surface of the insulation.

- Facade paint. Before buying, it is necessary to familiarize yourself with its specification. It must well withstand the effect of moisture and ultraviolet. Apply the paint will have to 2 layers, based on this, it is necessary to calculate the desired amount of material.

All materials must be purchased only in specialized stores that are ready to provide quality certificates for them. Working on insulation is a very laborious process and will be very unpleasant when tremendous work is spoiled by poor quality materials.

The order of work on the insulation of the outer wall by foam

Procedure for work:

- Initially, the surface should be prepared. The walls of the building are cleaned of the old paint and residues of peeling plaster. Otherwise, they can cause a poor clutch of plates with a wall.

- After cleaning, the surface of the walls must be treated with primer. This is done for better adhesion adhesive composition and wall surface. The primer does not need to regret, here the principle "the more, the better." A solution is caused by a wide brush with a long pile for better penetration inside the surface structure.

- After drying the walls, it is proceded to the laying of polystyrene foam. It is necessary to start from the bottom row, moving gradually up. The principle of laying polystyrene foams is the same as the brick: the joint between the plates of the top row should have to the middle of the lower plate.

- When sticking plates, it is necessary to be very careful with the preparation of glue. It dries pretty quickly, so it is necessary to prepare it with regard to the speed of work. Glue are prepared on a water basis. Its consistency should be pretty thick and resemble a solution for laying ceramic tiles. To stir the solution, you must use a mixer.

- The glue is applied both on the surface of the plate and on the surface of the wall with the help of a toothed spatula.

- After drying the glue, the plates of polystyrene foams are fixed with dowels.

- When insulation, it is necessary to take into account, the fact that the foam is poorly tolerates the sunlight, so the installed plates need to close the plaster layer as quickly as possible. According to the technology of insulation walls by foam, all work must be carried out within 3-4 days.

- A reinforcing grid is placed on the stoves, which is fixed using glue. To do this, it is applied a layer of glue to the surface, after which the grid is pressed into it and is closed by another layer of glue. After that, the surface is ground for a better clutch of plaster and plastering. There should be at least a day between the primer and plaster. After drying the plaster, the coating is maintained, ground and painted.

Warming of walls at home from the inside by foam

The inner insulation of walls with polystyrene foam is carried out in the same way as external. However, to save the time of repair, the insulation finish can be installed using drywall.

The insulation of the walls of foam plastic inside is produced using a plate of a smaller thickness of 5-10 mm. The use of thick materials will lead to the loss of useful area.