Metal furnaces compared to brick or stone are the most popular due to their low cost, impressive efficiency, strength and low weight. However, despite the long list of advantages, they have almost the same flaws. In this article we will look at everything you need to know about metal furnaces, as well as tell how to build one of the models with your own hands.

Content

Advantages and disadvantages of metal furnaces

Metal is a very durable material, but at the same time it has plasticity and compliance, allowing it to give it almost any shape. This is similar to ceramics, but it is capable of withstanding serious loads and temperature differences. There are many methods of metal processing, and therefore for the manufacture of metal furnaces really apply a variety of tactics, improving technical and operational characteristics with almost no increase in the cost of work.

Since bricks are the main competitor of metal furnaces, we will compare these two types of products. Thus, the seasonal efficiency of brick structures averages 70%, while metal is issued all 83%. This is explained by the fact that the specific strength of the brick is lost with a decrease in thickness, and the metal in the same conditions becomes only stronger. So it turns out that the weight of iron stoves is ten times less than the brick, and therefore the cost below.

Another indisputable advantage of metal furnaces is the integrity of the design. It can be easily transported and quickly installed, and with large brick structures it will not be released. Due to the low weight, metal products do not need to build a separate powerful foundation, and the installation consists only in the equipment of the chimney. For summer, mobile iron furnace can be removed at all in the storage room or the barn, freeing the place in the room.

Metal has a high thermal conductivity, so an easy compact stove is quickly warmed, but also quickly and cools. Fast warm-up ensures an increase in efficiency. In the brick stove, you must first wait for the beginning of the internal heat exchange, and before that, during the protest, almost all heat will fly out into the pipe.

Almost all the advantages of metal furnaces are due to the characteristics of the material. The metal is very dense and not porous, it cannot be dumped due to condensate, like a brick, it does not fear long breaks in the furnace and does not need an accelerated protostic after such downtime. Another important and convenient point is a metal furnace to be easy to certify and get permission from the fire service, which will save a bunch of time and money. There are even such models for which there are no permits at all, there would be an autonomous chimney.

But nothing is devoid of flaws, and metal stoves are no exception. The first thing to be noted is "not breathing" such structures, since the metal, unlike the brick, is not distinguished by porosity. When the brick oven cools, it absorbs moist evaporation from the air, and when heated, gives them back. Thus, a comfortable humidity balance is maintained in the room. Some craftsmen are facing metal furnaces with bricks to achieve such an effect, but in any case it will be weaker. At the same time, the design will lose mobility, lightness and strength.

Above, we have already mentioned that the metal is quickly heated, but also quickly and cools, so in order to maintain heat in the house, such a stove will have to constantly heat, otherwise it will completely cool for 2-3 hours. The solution to this problem can be the manufacture of a heating metal furnace of long burning. But in all cases, the design will be a permanent focus of fire, creating a risk of Ugon and Fire, so it is undesirable to leave it for a long time.

The main lack of metal furnaces in their fire hazard. Heating, the metal wall structures are hot, and can trigger the fire of close-based objects, walls of walls, gender, etc. For this reason, the Ministry of Emergency Situations is very difficult to obtain permission to install the furnace in a residential building - most likely, the boiler room will have to build.

As for the service life of such furnaces, it is not so long - up to 20 years. With regular use, even the worst metal burns out, and the walls are drowned. But even if your homemade metal furnace works for only 10 years, it will completely populate the costs of fuel and the ability to fully replace the design without redeveloping and repairing the house.

Metal selection

The operational characteristics of the future stove will mainly depend on the selected metal. It also affects the cost of work and the complexity of its execution. Consider the main options used to create metal furnaces.

Surrogates for stoves

Let's start, perhaps, with rather unusual raw materials for the production of furnaces - aluminum dairy bids. Despite the fact that instructions for the manufacture of such aggregates are quite common, this is not the best option. The fact is that for relatively high efficiency it is required to survive the spent flue gases. In the process of afterburning, the temperature is usually at least 400 ° C, and if you are going to make an eco-friendly stove, then the temperature should be all 600c. Aluminum melts at 660s, the structural aluminum has a strength of 140, and alloys - in 160-200. So it turns out that a good durable furnace from the bidones will not be released.

Ordinary steel

The usual structural steel has a strength limit to 400C (more than 2 h) and 600C (up to 2 h). For the manufacture of furnaces, only very thick steel is suitable - from 4 mm. However, even in this case, it is impossible to regular use, since such a furnace will completely proceed for one winter.

The exceptions make up the ovens of long burning and only in some cases. These are usually homemade structures in which it is possible to replace the elements failed without dismantling the entire furnace.

Heat supply steel

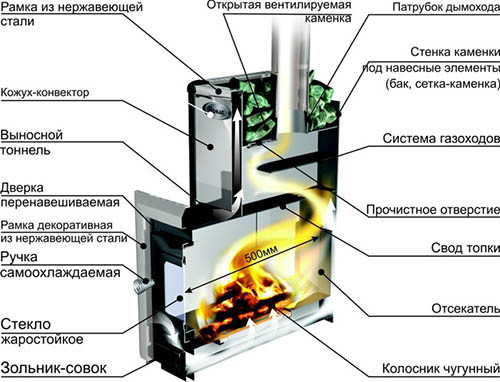

All factory ovens are made from heat-resistant steel using 1.5-3 mm specialist for this in thickness. Such structures serve about 20-30 years, differ in compactness, low weight and high efficiency. Factory stoves are usually already certified by all services and can be installed even in residential premises. They can be topped with cooking surfaces or low-power water heating registers.

At first glance, it seems that it is not difficult to make such a stove, but it turns out that even having the necessary material, you will need professional welder skills and special equipment. It is absolutely useless to try to cook heat-resistant stainless steel in conventional ways, because after mirroring under the arc, the material completely loses its qualities. Such a furnace will very quickly disperse on the seams, and all efforts will disappear.

However, make a metal furnace for home from heat-resistant steel quite real. The assembly of some models does not require major welding, and the compounds can be made in the fold, on the mustache or steel rivets. One such furnace is "Slobozhanka".

Casting for stoves

The cast iron is difficult to call a full-fledged metal, because only low price and mobility remained there. In fact, cast iron combines the properties of metal and brick. From the last he got fragility and a lot of weight. This material is distinguished by low thermal conductivity (well kept warm inside) and good heat capacity. This means that the cast-iron furnace warms up pretty quickly, and after the protruk, it gives heat to the room another 3-4 hours.

For the manufacture of furnaces fits the cast iron with a thickness of 6 to 25 mm. Thinner material will be very fragile, thicker can crack at the first furnace. Due to the high weight of cast iron stoves, they cannot be put right on the floor - it will be necessary to make a special concrete tie. For this, the floor must be disassembled and pour a smooth concrete site to the required level. Make your own hands the stove from the cast iron is unrealistic, because in handicraft conditions it is impossible to be processed.

Important: Cast iron furnaces are effective only for heating small rooms with an area of \u200b\u200bup to 60 m². Otherwise, their efficiency will be very small. They are mostly suitable for heating workshops, greenhouses or economic premises, where the severity of small animals (birds, rabbits).

Types of furnaces

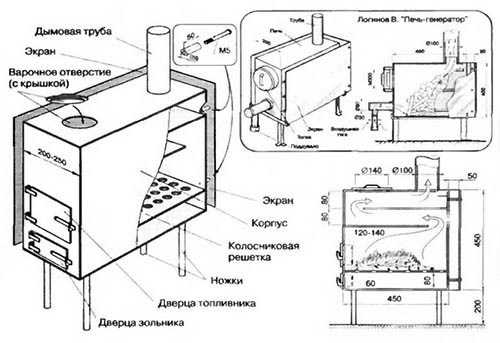

Since in most cases, homemade ovens are made with cooking surfaces, we suggest considering precisely the heating and cooking options. The image below shows the main schemes of metal furnaces.

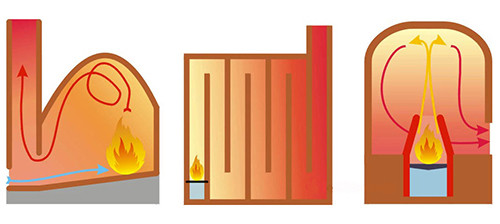

Classification by device:

- Chamber - in chamber furnaces, the furnace gases penetrate the special chamber, where they are completely burned due to the natural circulation. The design is such that actually creates a natural bonfire in a closed space. In the household products, the furnace chamber is combined with afterbirth and represents a single module - the burned. So that the survival occurs completely, the shape of the relief must be vaulted. The most visual example of such a design is the classic Russian oven.

- Channel - Channel furnace is depicted in the middle in the figure above. In it, the fuel gases are first tremble, then gradually cooled and headed on special channels located between partitions. In the process of movement, they give heat to the furnace housing. Afterburning inside does not occur until the temperature in the furnace reaches 400C. Such furnaces have low efficiency up to 60%.

- Capacked - the scheme of a corporate furnace is depicted in the figure on the right. The combustion products are rising and delayed under the vault of a special cap, where without the residue. After that, the gases are lowered down, giving heat body. Clearing such a furnace, it is necessary to warm up only a small segment of the cap. For this reason, its efficiency is quite high and can reach 75%.

Features of metal furnaces

Since metal is the main material for the assembly, then it is he who dictates the main operational characteristics of the furnaces. Consider how the metal demonstrates its properties in various designs. Thus, its thermal conductivity relative to heat capacity is much higher than that of a red burned brick, so the metal is a bad heat drive. He quickly absorbs him, heats up and also cool down. However, if you consider the properties, you can construct the oven so as to achieve high indicators with minimal warming. Due to the high connectedness of metal products, you can implement the principles of fuel combustion, not applicable to brick furnaces. The image below shows the schemes of the device from metal furnaces.

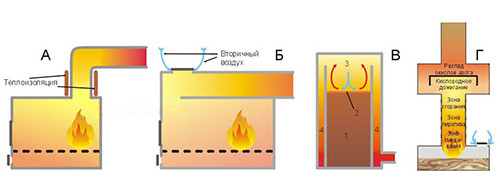

Consider how the designs of metal furnaces are functioning depending on the schemes:

- Chamber - This furnace is shown in the figure above under the letter "A". In fact, this ordinary bourgeitarian, whose "ancestors" appeared in the year before last, but demanded too much fuel. After the revolution in Russia, the design was improved - a grace with a confusion was inserted into it, rooted the chimney to 2.5-3 m and insulated it. The alternation arch on the minimum firebox was a warmed vertical section of the chimney pipe, in which the coarse gases were made. The design feature is that it is self-regulating: when a complete protostka is going, the hem bandwidth is missing, in order to remove all the heat gases, curvatures appear in the horn, fully surviving combustion products. Only after the complete cutting of the gases can pass through the pipe. Since the gas temperature at the outlet of the pipe is close to 100 ° C or some condensate can be speech. You can clean the chimney from soot only once a year. The efficiency of such a metal wood stove (can be dried and coal) is about 60%.

- Channels - in the figure below the letter "b" shows the bourgeois, converted under the channel structure, but the similarity only externally. Since the metal has a high thermal conductivity, there will be no prose from a complex labyrinth of gas pipes, and therefore it can be left from it only one knee. It will separate the furnace and the hurrying chamber. The secondary air for afterburning penetrates through the holes in the burner (if there is a cooking surface) or through a special adjustable air choke.

Since the hurry of the flue gases occurs in one place, the efficiency is 70-80%. In this case, the specific thermal power of the furnace is rather high, the efficiency of work does not depend on the parameters of the chimney or the force of thrust, as in the usual bourgeois, which is very convenient. Since the main heat occurs in the afterburning chamber, the furnace can be used in two modes: fiery and long burning. It can be trammed with almost any solid fuel, and adjust the power does not increase the portion of coal or firewood, but by twisting the air choke. If you use a good wood material or high-quality coal, the flushing of chimney can be remembered every 4 years.

The breathtaker for such a furnace is better to do from heat-resistant steel, giving him the shape of the trough. For the manufacture of the housing, use ordinary steel with a thickness of at least 4 mm, and it is better to get the cast iron for the cooking plate or a thick 8-10 mm steel. The stove is recommended to do the removable, especially if you decide to make it from steel, because sooner or later it will procee and requires replacement. - Long burning furnaces - the cap scheme was so effective for metal furnaces, which made it possible to abandon the flame: no metal cap is capable, not overheating, absorb only heat, how much is released by fire. The furnaces were transferred to the regime, which simultaneously made it possible to extend the period of heat transfer to several days for firewood and 10-30 days for coal. A simplified scheme of such a furnace without an oxygen supply system is shown in the image above under the letter "B". In it, the fuel (1) is tweaked at the surface itself (2), where oxygen comes. Pyrolysis splits fuel to volatile components that rise up and burn in the cap (3), highlighting about 60% of heat. To increase the efficiency, it is necessary to install a gas shirt (4) to install a gas shirt (4), where the boiler gases can be treated. To bring the efficiency of such stoves, you can already up to 80% and even more, therefore it is the most common type.

If you decide to stop your choice on this embodiment, some moments should be taken into account. So, despite the fact that for such furnaces you can use any solid fuel, they will be most effective only in during the extracts of the fuel for which they were developed. Moreover, the fuel should be as dry as possible, and it is extremely undesirable to exhaust it until the complete combustion of the previous party. In the chimney of such furnaces there will always be a lot of toxic condensate, so it should be secure.

For the manufacture of the case, you can take an old iron barrel or a large gas cylinder. - Oil-pyrolysis - are also known as ovens on working out. Very economical option that is popular with self-taught peopling. The principle of operation is simple: the work is poured into the tank, ignite, fed through the air choke oxygen. The combustion is not too strong, but sufficient to evaporate the spent oil. Oil pairs are sent up into a special compartment in the form of a pipe with perforated walls, through which air penetrates. Couples are burning and followed in a silent with a partition that delays nitrogen oxides in a suitable temperature zone until they break down and do not allocate energy.

IMPORTANT: According to the rules of fire safety, it is prohibited to use in everyday life on working out, so they will not meet them on a wide sale.

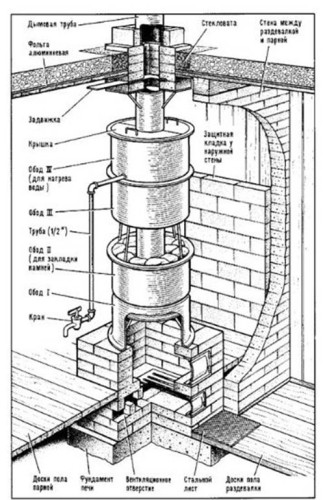

Make a baker for a bath

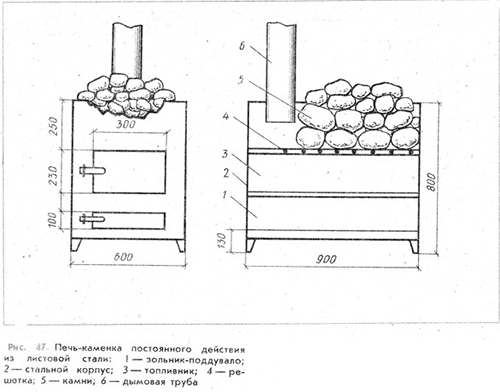

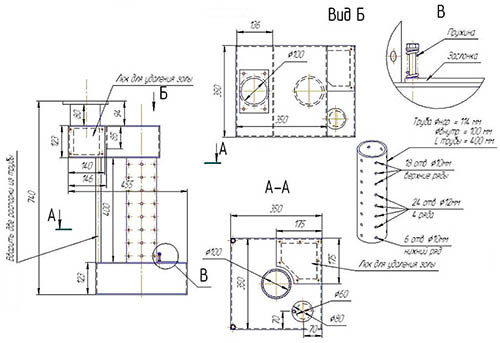

In this chapter, we will tell how to make a metal furnace made of leaf steel by brick. This design will not be mobile, but its fire safety allows the use of a furnace within a house or even a wooden bath. For work requires welding equipment and at least the initial skills of handling it. Also need Bulgarian and diodes 3-4 mm. The main material will be leaf iron 2-3 mm thick. For the frame it is better to take the reinforcement 8-10 mm.

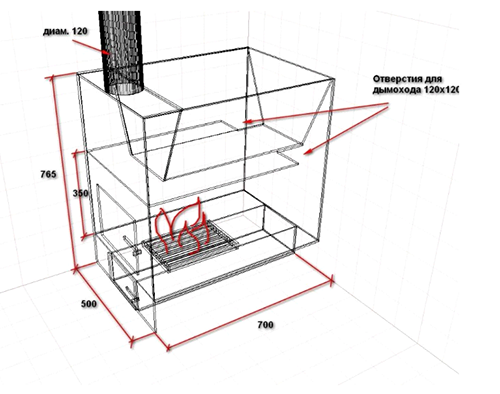

The image below shows a drawing of a metal furnace. At the end of the article you will find a few more drawings of other designs.

Important moment: choosing such a furnace, you should correctly select the diameter of the chimney, since the thrust force depends on it. It also affects the weather conditions - the warmer and wet air, the weaker the thrust. In too narrow chimney, the gases and the air will be mixed and do not have time to come out, which will create a smoke plug. Too wide tube is also not suitable - there will be very slow gases in it, and the inner walls will quickly clog.

Metal oven do it yourself:

- First of all, you need to build a foundation for stove-Kamenka. To do this, arrange a wooden formwork with a height of 20 cm so that 1x1 m square turns out.

- Fit the reinforcement into one layer, making a grid of rods with cells 20x20 cm. It is important that the reinforcement does not touch the ground, so it is to have it for pre-robbed pegs (segments of the same reinforcement) and knit on weight.

- Prepare a classic cement-sand solution in a ratio of 1: 3 (1 part of the cement is not lower than M400 and 3 parts of river sand). For the strength, you can add more of the rubble. Fill formwork, cover the surface with a plastic film and leave to dry for 2-3 weeks. Once a day, spray the frozen concrete with cold water and cover again, otherwise it cracks.

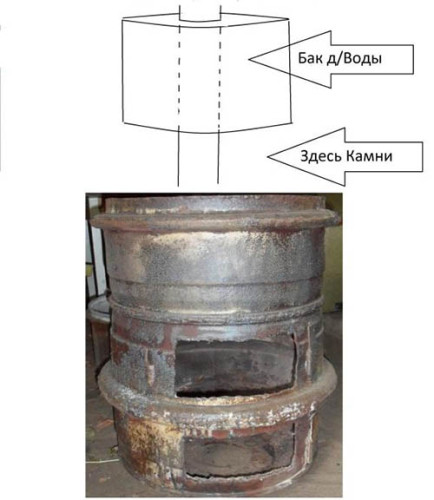

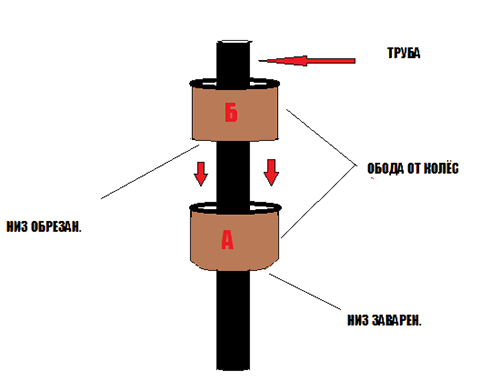

- Take the rear rim from the wheel and make all the holes on it, except the central one.

- From the second rim cut the convex top, insert the first and brew in it. It is important that the compound is hermetically, because hot water will be inside.

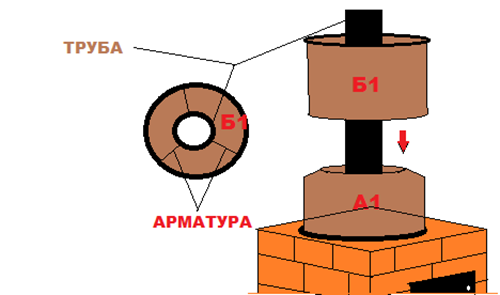

- On the inside of the second rim (b) from 3 sides, an equal distance from each other makes the reinforcement and remove it into the pipe to give the stiffness design.

- At the bottom of the first rim (a), make a round hole 25 mm and breed a pipe of the corresponding diameter to it. A tap for draining water should be screwed into the pipe.

- Make accurate copies of rims A and B (A1 and B1). Space the rim B1 on the pipe, turn the rim A1 and weld it to the end of the pipe. Take up the rim B1 and strengthen it with reinforcement for stiffness, as in the previous case.

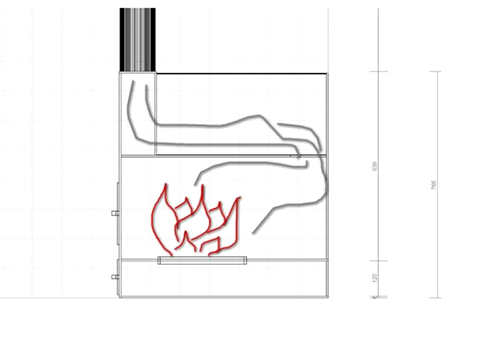

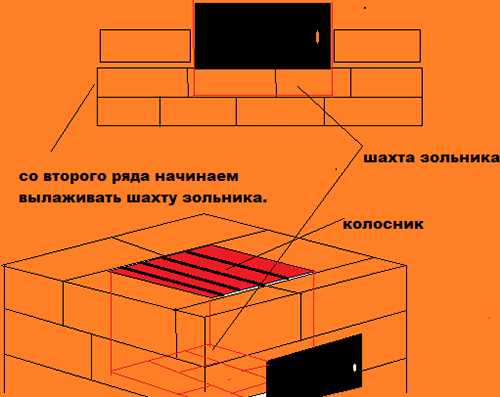

- When the foundation is completely dry, remove the formwork and put the brick using instead of an ordinary clay masonry solution.

- The place where the oven will be located, you must fully set the fire safety brick.

- Make the base completely brick, and by the second, start to lay out the ashpan with a confusion. Through it, you will clean the ash, in order to enter fresh air to create a good thrust. The length of the roller must be less than that of the heat chamber.

- Install the door pondered, sow it with brick, make another row and install a grille at the ashtarine mine.

- Aftercender, put two rows, leaving the place for the door of the fuel chamber. On top of the door, lay out a couple of rows.

- Leave the laying to dry for 2 weeks, opening all outputs for air circulation. After the specified period, the stove of 1.5-2 hours is touched.

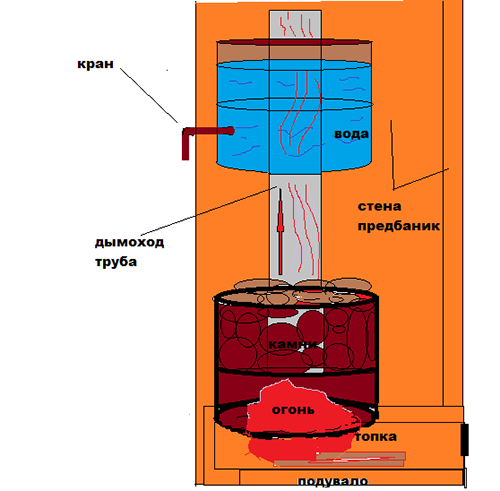

- The image below shows the finished tube that you need to install on the resulting brick design. It has a heater and a hot water tank.

- It is worth noting that the weight and size of the metal furnace will be quite impressive, therefore it is easier to divide it into the components and collect already inside.

- The upper part of the chimney strengthen the reinforcement rods, one end welding to the pipe, and the other superpower into the wall. To attach to the wall, use a steel corner or metal plate.