Transform the outdoor part of the house in a short time can be using wall panels under the brick. It will require smaller material costs than when lining with brick walls. In favor of such a choice and other advantages of wall panels for home.

Content

What good wall panels are good

Wall panels for home have the following advantages.

- Small weight, thanks to which you can change the appearance of the house, without loading it. Additional fortification of the foundation will not need, which reduces costs.

- Visual resemblance to facing natural bricks.

- Practicality: In order to clean the contaminated wall panels with their own hands, it is enough to pour them from the hose water. The laying of bricks need a periodic sealing of cracks with cement mortar.

- The absence of pores and microcracks is an obstacle to the spread of mold and hazardous microorganisms.

- Mechanical strength: panels (especially base) are able to withstand strong blows.

- Resistance to ultraviolet, atmospheric precipitation, temperature drops and winds. Operation of the finishing material is allowed within the ambient temperature from -50 to +60 ° C.

- A wide range of colors and shades allows you to choose a panel to other materials finishing materials.

- The possibility of using both outdoor and interior decoration.

- With the help of the "Under Brick" panels, you can quickly reconstruct any building.

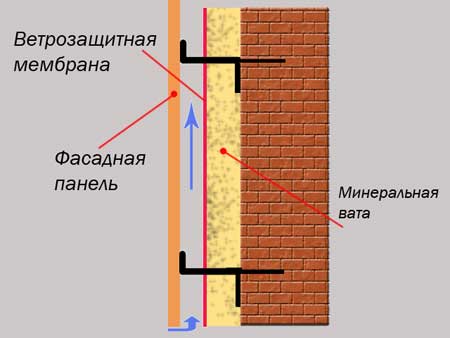

- The ability to create ventilated facades. Airspace remain between the panels and the wall. Due to this, the mold is not formed on the wall.

- Long service life.

Types of wall panels

Depending on the material used for manufacture, the following types of wall panels with imitation of brick masonry are distinguished.

- Vinyl siding: produced by casting and molding. It is distinguished by ease of installation and relatively low cost. Special, thicker and durable panels are used for cladding.

- Metal panels: made by cold molding. Corrosion resistance is provided with zinc coating. Because of the high weight, it is used for cladding mainly industrial buildings with a reliable foundation. Serve effective fire protection. Installation is complicated by the need for reliable fastening.

- Fiber cement: universal finishing material used for cladding industrial and residential buildings. Production is based on forming a mixture of cement and cellulose, resulting in a durable material. The panels are characterized by low thermal conductivity, resistance to atmospheric precipitation, fire safety.

Important: Metal panels are fixed with stainless steel screws to galvanized metallic profile.

Release panels of two types:

- uniform: usually manufactured based on polyvinyl chloride with special additives that prevent deformation under the influence of temperature difference;

- combined: The thickness of the wall panels of this type is somewhat more due to the additional layer of the insulation.

Tip: For cladding of the base, you need to use the panels of the darker color. In this case, the building will look harmonious.

Installation technology wall panels "under the brick"

There must be the following tools for mounting wall panels:

- bulgarian - for cutting plastic panels;

- electrolovka - to cut metal panels;

- roulette;

- marker construction;

- level;

- perforator;

- screwdriver or curly screwdriver;

- wall cleaning spatula;

- shutter toothed - for applying glue;

- hammer 0.5 kg.

Instructions for installing wall panels consists of a description of the following steps.

- The wall surface is checked: the perfectly smooth base of the panel can be mounted using glue and dowels. The wall with defects are purified from mold, processed by an antiseptic. Cracks close up with cement mortar.

- Installing wall panels for home with uneven walls is performed after mounting the crate. For this purpose, metal profiles and wooden bars are used. At first, a horizontal plank-tide is mounted (condensate will be dragged on it), which is closed by a masking profile.

- On the wall at vertical marks at a distance of 0.3-0.4 m fasten elements of the crate. Additional profiles must be in the corners. Installation of vertical profiles (or rail) is carried out using suspensions that smooth the irregularities of the wall. The position of profiles (RESEK) is checked and adjusted with the help level.

- The thermal insulation material is laid between the vertical elements of the crates (if insulation is envisaged). The method of fastening (glue, dowels are used) is selected depending on the type of insulation. The gap between the main wall and panels is 4 cm. From above, the insulation (extruded polystyrene foam, mineral or basalt cotton wool) is covered with windproof membrane. Wall panel laying circuit is shown below.

- Installing the "Under Brick" panels starts from the bottom angle. If the installation of the decorative element is not provided, the panel from the angle side is spilled under 45 °. Fasteners of thin panels (14 mm) are performed using selflessness. Thicker (base) are mounted on metal plates.

- After installing the first row, the second is mounted. Each subsequent row - after the previous one. The panels on the principle of the "groove comb" are connected. The vertical position and deviation horizontally controlled and is corrected using a level. Pruning plates that do not fit in a row is performed using a grinder.

- The jokes are filled with a facade grout, selected in color. Dry mixture is diluted with water to the required consistency and applied with a spatula. After drying, the incision of the grout is believed and washed off with water.

Tip: Sucks around the perimeter of windows are made of plastic. Decorative stucco decoration is also possible.

Care of facade wall panels

It is necessary to periodically inspect the "under the brick" panels, if necessary, change the fastening elements. Pollution eliminates a wet rag. The frequency of testing and cleaning is once a year. Compliance with this rule increases the service life of the finishing material.

In conclusion, the article on which there are and how the wall panels for home - video are installed, clearly demonstrating the work of the specialist.

The manufacture of sandwich panels for optimal technology is the pride of our company. For more than 10 years, Stal Pro LLC is in the list of the best wholesale metal structures. We are ready to offer you a huge range of services from the sale before the construction of hangars. I know with our suggestions, and we will pick up for you the best! http://sp-panel.ru/production/

The team of Stal-Pro LLC