In homes or apartments that have more than one floor or attic, installation of the stairs is of great importance. The modern staircase is not only a structural element, but also part of the interior that should harmoniously fit into the overall design. It should be not only comfortable, because it will have to use it several times a day, but also beautiful. Recently, glass staircases are becoming increasingly popular. Due to the use of glass as a finishing material, the staircase seems easy, air and does not take up much space.

Content

Glass design only at first glance seems so fragile. Thanks to the use of modern technologies and materials, these stairs are quite durable and can withstand not only the weight of a person, but also a drop in a heavy item without the appearance of cracks on the surface of the glass stage. About how to make a solid staircase from glass with your own hands, let's tell further.

Materials for the manufacture of glass staircase

Construction of the staircase from glass and its installation is not fundamentally different from wooden or steel structures. For the island of stairs, a tree or steel is used. More often give preference to the second option, since steel with glass is combined more organically. Basically uses stainless steel or with applied chromed coating. The brilliance of the stainless steel will give the glass of greater sophistication.

Steps and risers of glass stairs are made from high-strength glass - triplex. This material is made of several layers of tempered glass, which are soldered with each other. A special polymer transparent material is stacked between the glass layers, which makes the glass stronger.

Such a "cake" can withstand heavy loads and serves for a very long time. Thanks to the use of tempered glass, the surfaces of the steps almost do not scratch, which allows you to walk along the stairs in any shoes. One of the main advantages of using glass for the installation of inter-storey stairs is its resistance to the effects of the external environment and unpretentiousness. The glass stage will never start rust, it does not need to be painted or coated with antifungal compositions. It is necessary only in time to wash with special compositions in order to avoid divorces.

For fastening glass details of the stairs, special fasteners are applied - decorative bolts with a wide head so that when spinning they do not damage the glass.

Types of glass stairs

Consider what types of glass stairs are:

- The most common option for a glass staircase is a marching design. They are single-hour or swivel. The latter consist of several marches that are mounted in the opposite direction and have a swing pad. Such structures are mainly used in rooms with a limited area, where the installation of a single-hour staircase is simply impossible due to the large angle of inclination of degrees.

- Design on largests. The hospitals call special supports that are mounted in the wall adjacent to the stairs. Steps are installed on the hospitals. This design is very easy to install and does not require the presence of cososov, which in combination with the use of glass makes the staircase very light and air.

- Console stairs for their design are something resemble previous. With the only difference that the step is not attached to the wall, and its design is mounted in the wall. Such stairs usually do not have a balasine and rail.

- Screw structures. Screw staircases are installed in homes where there are restrictions on the area. This design is technically more complicated, but allows you to save space without prejudice to the ease of use.

Installing a simple glass staircase with your own hands

Calculations and calculations for glass staircase

Marsemes of non-turning stairs with one Kosourg are considered the easiest designs. That is why in the absence of problems with space, it is better to mount this type of staircase.

A marching glass staircase consists of:

- Frame.

- Glass facing.

The frame of the flight staircase made of glass consists of several main details:

- Kosouras. Kosomers are called support beams on which the design itself is kept. For the manufacture of cosomers, channels or 2-meter beams are most often used. They have a sufficient margin of strength to serve a long time and withstand heavy loads.

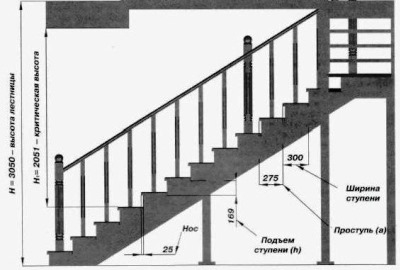

- Stages. This structural element consists of two parts: a sticky (horizontal part) and a riser (vertical part). Installation of the second part is optional, but in the presence of small children or people with health problems, it is desirable. The width of the sticking should be sufficient to comfortably use the staircase. The height of the stage is determined individually, however, for a healthy person it is approximately 200 mm. For an elderly person, it is better to reduce the height of the stage to 150 mm. For the manufacture of frames of the glass marching staircase, steel corner with a shelf with a thickness of 4 mm in size from 25x25 mm is used.

- Fastening. In order to fasten the steel boosters to the floor of the first floor and overlapping the second, steel brackets welded from a sheet with a thickness of 5 mm are used. You can booster to the brackets to the bolts and weld.

Before starting the installation, it is better to make drawings of a glass staircase. This will help assess the scope of work and the need for materials.

Important parameters for the calculation of the stairs is:

- The length of the stairs is the distance from the point of attachment of the Kourow on the first floor to the height of the top point of the floor overlap. The length of the stairs is equal to the sum of the depths of coming.

- The height is the distance from the top point of the overlap to the floor level of the first floor. The height of the stairs is equal to the sum of the heights of its steps.

- Courty-old length. Calculated by the formula:

- √ A. 2 + B. 2where a is the height of the stairs, in its length.

For example, with a height between the upper point of the overlap of the second floor and the lower point of the floor, equal to 3 meters and the normal height of the steps 0.2 meters - you need 15 steps. With a medium depth of a sticky 0.3 meters, the base length of the stairs will be 4.5 meters. At the same time, the length of the rower will be equal to:

- √ 32 + 4,52 \u003d 6.36 meters.

Knowing all the parameters, you can proceed to the workpiece of parts. Preparations of steps are better to cook in advance by a specific template. After removing all the sizes, you can go to the glass workshop to order glass parts. It is advisable to do this in advance, as you cut 15 steps and 15 risers - the matter is not one day, and they still need to drill holes under fasteners.

Phased installation of a glass staircase

The process of mounting the staircase of the glass is as follows:

- Installation of the beams of the cosome. One of them is welded to the ceiling plate by one end, and to the base of the floor the second, and the second, in addition, is welded to the adjacent wall to the mortgages. This will provide the entire design additional strength. When installing the platform, it is necessary to check the correctness of their position. The angle of inclination should be the same, as well as the distance between them anywhere. If there are deviations, it is necessary to conduct an adjustment. If the boosters are exhibited correctly, you can brew the design.

- After the beams are welded, you can welcome the billets of the steps. It is necessary to do it carefully, so that the steps were smooth. For this, a robust thread is stretched along the platform, which will be a guide to install metal structures.

- After they are welded, you can connect their corners. The result will be a complete frame of steps and the entire staircase march. In the production of welding work it is worth remembering that poor-quality seam will be well noticeable under glass, so cooking is needed very carefully.

- After the end of the welding work, it is necessary to well clean all the seams with the help of an angular grinder (bulgaris) with a credit circle. Next, it is necessary to predict the surface and paint in several layers. To do this, it is better to use enamel with an additional brilliance. Naturally, it is more expensive, but such a staircase will look amazing. If the steel is stainless, you can not paint it.

- The last step is installed glass steps and risers. If necessary, balusters and railings are installed. They are made of chrome steel pipe. Such a staircase will be very interesting to look in the interior in the style of minimalism or "High Tech".

Installing the screw glass staircase with your own hands

The advantages of the helical glass staircase are compactly. Thanks to such a design, it takes up little space and can be used in conditions of lack of space. However, the design of this type of stairs is quite complex for design and installation, so without any special experience of welding work, it will be difficult. The central part of the design of the spiral staircase is the central column, which will keep all its weight on himself.

For montage of colone, a steel pipe of a large diameter is used.

Procedure for work:

- Steps in the screw staircase have the shape of the sector. Its dimensions depend on the diameter of the stairs and the number of steps. To calculate the parameters of the screw staircase, a special technique is used (we will have to recall the course of trigonometry).

- Steps are digested from the corner, which is welded to the pipe. Its diameter should be greater than that of the Pipe Colon. The finished stage is ridicked by the column, then welded.

- After all the steps are welded, the metal structure is cleaned, it is ground and painted, after which glass elements are installed on it. In order to decorate the design of the room, you can mount the glass staircase with backlight.