The person is designed in such a way that it can live only at certain temperature indicators. In the cold season, people need to make their housing. In apartment buildings, this problem is solved by the relevant authorities with the help of central heating. And in private homes, the owner must take care of their living conditions. And sooner or later, there will be a question of high-quality heating, and the earlier it is to solve the entire complex of tasks related to the installation of the heating system, the better. Ideally, planned work related to heating must be solved at the design stage of the house. In parallel with this, it is necessary to take care of the development of the chimney. It is important to choose an effective type of heating equipment and a type of boiler, to ensure its full and safe operation.

Content

The variety of heating devices during operation has a different ratio of consumption and heat generation, a different level of combustion waste emissions and require compliance with individual fire safety measures.

The design of the boiler directly depends on the fuel on which it works. As resources, modern heating devices can use both gas and coal, firewood and pellets, and can work on liquid fuel.

Features of the installation of chimneys

- Starting the installation of the chimney for a gas or coal boiler, carefully read the passport, and at the time of installation, try to accurately follow the instructions. Despite the large variety of models of heating boilers, individual building standards have been developed for each instance.

- The main function of any chimney is to bring into the atmosphere of gases resulting from the combustion of fuel. It is important to choose such a chimney design that will meet the requirements of the carbon monoxide for your boiler.

- There is a list of requirements that relate to all types of chimneys and are the basic rules for installing them in the premises.

- for the construction of any chimney, only heat-resistant types of materials are used;

- the heat resistance indicators of the materials used should not be below the norm;

- the design of the structure of the chimney should be hermetic;

- sealing the chimney pipe and its component parts are made only by heat-resistant sealants;

- in the process of installation, it is important to ensure the growth of the chimney so that the carbon monoxide obtained as a result of the boiler does not get into residential rooms;

- chimney is always installed strictly vertically, the allowable deviation from the axis can be no more than 30 ° C on a stretch of less than 1 m;

- narrowing or extension of the contour is not allowed;

- the diameter of the chimney should be no less than the diameter of the heating instrument chimney;

- the chimney tube should rise above the roof level by at least 0.5 meters, which will ensure the maximum derivation of carbon monoxide and will prevent possible air in the chimney.

Extract of the chimney and its size

- The traction is the main indicator of the correct operation of the smoke. It is formed due to the difference in temperatures and different input levels and pipe output. Hot air in chimney rises up and outdoor. The difference in air pressure indoors and on the street also pushes the combustion products of the heating device.

- Without good thrust it is impossible to ensure the stable operation of the heating boiler.

- Before starting the construction of walls and overlaps, you must select the appropriate design of the device, and then decide on the number of channels for the removal of flue gases. Their quantity is calculated at the calculation of the total area of \u200b\u200bheated space, and the diameter of their sections is from the characteristics of the selected boiler: power, type of fuel and the list of other individual requirements specified in the certified passport.

- If, as a result, the diameter of the chimney will be more calculated for this boiler, it will not increase, but, on the contrary, will lead to a decrease in thrust. Reducing the power reduction will lead to a deterioration in the work of the heating device and systemic interruptions in its work. If, as a result of the installation, the diameter of the exhaust hole will be less than the calculated, it will significantly worsen the removal of gases and can generally lead to the boiler stop.

- The thrust force has a direct dependence on the height of the chimney. The length of the pipe is determined on the basis of construction standards even at the design stage.

- the height of the chimney must exceed the level of the skate by 0.5 m;

- the axis of the channel is obliged to pass at a distance of 1 m from the window;

- if the chimney axis is at a distance of more than 1.5 m from the facade of the building, it can be flushed with a roof level;

- for a flat roof, the height of the chimney is less than 1 m is not allowed;

- if the vertical size of the chimney exceeds 1.5 m, it must be further consolidated to prevent collapse.

Chimney production: Materials

- As early as our great-grandfather, traditional chimney pipes were built of bricks, but as practice has shown, the brick turned out to be far from the best material for these purposes.

- Nowadays, stainless steel, galvanizing or ceramics are increasingly used for chimneys. The use of these materials is due to the fact that modern boilers have a higher efficiency of useful heat at lower combustion products temperatures.

- The brick and tubes from asbestos gradually go into the past, Hungarian Furanflex and special protective sleeves came to replace them.

- Materials for the construction of gas pipes should be perfectly smooth, since the corrugated surface is not able to create a craving, safe for health.

Galvanized pipes

Galvanized pipes under the influence of the external environment are corrosive, as well as any other metal. The life of their operation is no more than 3 years. It is possible to extend the life of galvanized pipes by protecting them with a special coating when installing. Processed drugs against pipe corrosion will live at least 2 years.

Asbestos cement pipes

In the old days, asbestos cement pipes were widely used for chimney pipes. However, they have a large number of shortcomings compared to modern materials:

- asbestos does not withstand the temperature load over 300 0WITH;

- installation of such pipes is quite laborious and has certain difficulties;

- chimneys from asbestos cement have problems with the tightness of the joints, quickly absorb moisture, and their overheating leads to damage to the material and the formation of cracks;

- however, they have a low cost.

Chimney of bricks

The brick chimney due to the effects of condensate quickly comes in disrepair, the moisture impresses it, and, passing through it, destroys the ceiling and walls.

Protective sleeve

- The chimney tube decorated with a protective sleeve has the form of a multi-layer shell. Its diameter must accurately coincide with the ventilation channel. The conclusion constructed in this way protects the flue moves from the destructive effects of hot combustion products.

- In the same way, it is customary to seal the ventilation channels.

- The use of sleeves improves traction and prolongs the shelf life of the chimney.

Furanflex for chimneys

Furanflex is an innovative material that has become applied to the smoke setting is relatively recently. It is very durable, reinforced with special fibers, plastic. Chimney from such a material does not respond at all to condensate, its temperature load ceiling reaches up to 200 0C, and the total area has a low thermal conductivity.

Stainless steel

For the manufacture of metal chimneys, both stainless and ferrous steel are used. However, the use of ferrous steel has long been irrelevant, since it is unstable to the effects of aggressive media. The stability of the same stainless steel to the effects of soot and condensate is due to the presence of titanium, molybdenum, nickel and other metals in its composition. Such material has increased heat-resistant, tightness, does not form condensate and has a perfectly smooth surface. The presence of such properties favors the creation of maximum thrust.

Ceramic chimney

The ideal option for solid fuel boilers are ceramic pipes. They have excellent properties for this application:

- not exposed to condensate;

- have a high degree of refractory;

- their temperature limit is 1200 0WITH;

- the material is highly resistant to mechanical damage, and is not affected by the atmosphere.

Chimney for solid fuel boiler

- Each heating device has a technical description in which the requirements for its device are set. The general rule for each modification is the level of chimney height for the boiler. According to standards, it should not be less than 5 m.

- Boilers on the gas and on firewood, as well as fireplaces and furnaces have the same principle of the distribution of heat energy and, accordingly, the design of the chimney. The chimney channel of such a device requires a periodic cleaning and removal of accumulated soot.

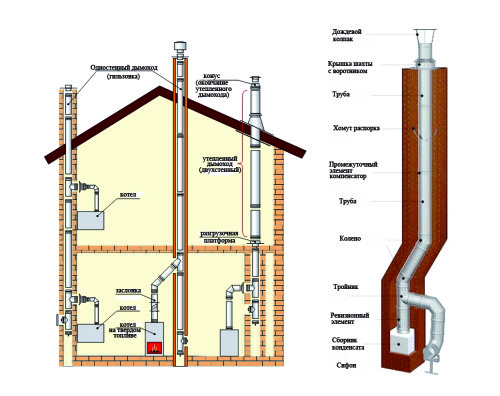

- There is the possibility of installing the chimney inside the building, but the best option, of course, will be the pipe removal beyond the dwelling. Chimneys with an internal chimney are most often used in single-storey private houses. If necessary, such chimney is easily converted to another heating device. It will be advisable to keep the scheme of installation of such a chimney for the boiler in case of its alteration or repair.

Gas boiler chimney

- Equipment manufacturers are constantly improving their products. In accordance with the changed characteristics of gas boilers, the rules for their installation have changed, the previous standards have undergone large changes, now the chimney is not allowed in brickwork thick in a brick.

- The efficiency of gas heating devices was significantly increased, the temperature indicators of combustion products decreased, which ensures the absence of condensate, and this leads to the need to increase the diameter of the pipe cross section to create a normal level of thrust.

- If the pipe design has "tees", in this case the angles of the removal and the installation of the revision door becomes important.

- To reduce the condensate, the pipe heat insulation is used, it contributes to a faster heating and keeps heat longer.

- When installing, it is necessary to avoid contact of the chimney with roofing overlap, this requires the rules of fire safety.

Chimney inside the wall of the house

- If the chimney is installed in the wall of the house or in a special brick mine, it does not require additional work on moisture protection, most importantly, withstand strict masonry geometry. In order to avoid the formation of abundant condensate, it is sometimes additionally insulated. To do this, at the base of the shaft make a small ventilation hole for air circulation in the pipe.

- The laying of brick does not guarantee the absence of carbon monoxide in it, they will be able to accumulate and leak into the premises. In order to avoid burning products to the room, try to connect the joints of the pipe with maximum tightness. The visor, set on the output of the pipe that protects it from the fall of different objects, should not prevent the free exit of smoke.

Chimney for a condensation boiler

- For the heating boiler of this type there are two types of chimneys:

- coaxial when the output is installed in the wall of the room;

- separate chimney, providing a window against the outer wall.

- Specific requirements for the installation of separate chimney create difficulties when it is installed, so it is used extremely rarely.

- Coaxial chimney is considered the most common and convenient installation, its device helps to increase the efficiency of the heating boiler.

- An option is also possible when a pipe built into the inner wall of the building is connected to the coaxial chimney. However, this is possible only to be realized only at a height of not lower than 5 m, so it can be considered only for the upper floors of houses.

- For additional safety, the chimney can be installed on the street, while the boiler should be made from the inside of the building, closely at one of the walls. In this case, the heating device and chimney are combined with a gas duct.

- This method of installation has many advantages:

- it is easy to operate;

- has a high degree of security;

- easily accessible to repair;

- from such a chimney, carbon monoxide will never enter the premises.

Chimney for boiler: Mounting errors

- For the installation of chimneys, you can only use materials intended for them.

- You can use one chimney for several boilers only on the basis of engineering calculations.

- It is impossible to operate the chimney with a low degree of sealing.

- You can not use one sleeve for several chimneys.

- It is impossible to repair and install chimneys to people who do not have special training.

- Chimney is quite a difficult design that has many variations, and each correspond to the stringent installation rules. Before installing the chimney thoroughly examine the requirements and norms for the installation of the chimney and for the installation of the heating instrument itself.

- When carrying out installation work, a professional approach and a high level of knowledge in this area are needed. Before you set the chimney for the boiler with your own hands, appreciate all the features and accept the right decision.