There are many modern materials designed to finish the facade of the building. Moreover, most of them not only protect against the negative impact of natural phenomena, but also makes the building more attractive. Among the latest technologies, a special place is occupied by a ventilated facade.

Content

What is a ventilated facade

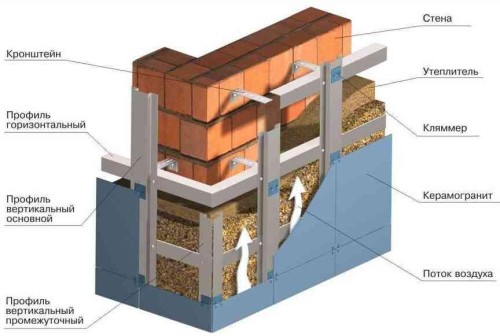

In essence, this design consists of two main parts:

- metal crates (attached to the wall);

- finishing material (mounted on the crate).

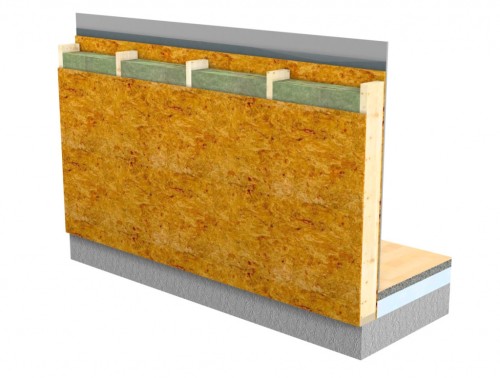

If desired, the insulation is stacked between the wall and facing material. It is best to take advantage of mineral wool plates or polyurethane foam. The membrane film is necessarily placed, which protects the design from the wind and the negative impact of the wet environment.

An integral part of the facade is the presence of a ventilated space that is created between the trim and the wall. Thanks to this, the facade "breathes", and the house is reliably protected from heat loss in cold days and excessive overheating in the summer.

Hinged ventilated facades can be made from various materials:

- metal;

- plastic;

- porcelain stoneware;

- fibrcement;

- asbestos cement;

- composite products.

Characteristics of construction

The device of the ventilated facade is possible on any surface. And the dimensions of the design can be adjusted to your taste. For this reason, this technology can be considered the most practical and in demand.

Ventilated facades are characterized by a solid operational period. Its minimum service life is 45-50 years. When using high quality materials of well-known manufacturers firms, the operating period may exceed 100 years.

The technique of installation of ventilated facades will take the minimum amount of time. This is due to the fact that it will not be necessary to engage in careful surface preparation. Just the sealing of too large cracks occurs, and areas with mold and fungus are removed.

If necessary, the facade is quite simply dismantled. If you need to repair a certain secession section, then it is carried out without problems. And thanks to the wide range and variety of color solutions, any design of the house can be made.

Preparatory stage

Preparation of the surface includes:

- removal of interfering structures: decorative elements, various fasteners and lighting devices;

- sealing large cracks;

- removal of fungus and mold;

- marking work.

The sealing of large cracks is performed to prevent overcooling of the wall. Does not save the installation of thermal insulation material. In places, the cracks will accumulate condensate, which will lead to the destruction of the cladding.

Surface markup involves the definition of the location of the lower horizontal profile, which will be a guide to create a crate. To determine the maximum surface deviation along the entire length, a plumb is used. Also immediately should be noted the places where the brackets for the facade plates will be attached.

The most important when conducting marking works is the correct determination of the horizontal plane. The adjustment of the vertical level is made without problems in the process of building the building.

Creating a frame and facade insulation

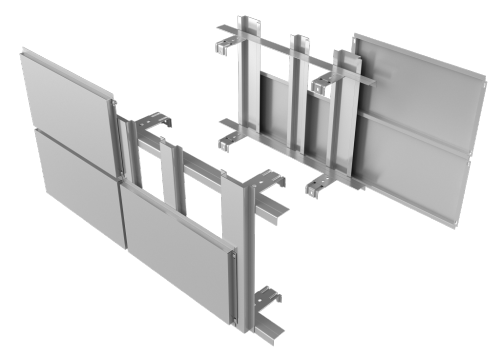

Installation of facade plates is made on a pre-made frame. To create a frame used:

- profile;

- brackets;

- clammers;

- rivets;

- dowels and screws.

The framework of the carcass implies the following actions:

- drilling by perforator holes in the wall;

- fastening the lower horizontal guide;

- installing brackets for vertical profiles;

- fastening for each bracket with anchor dowels of paronite gaskets;

- laying the heat-insulating material through the slits made for brackets (the insulation is mounted without the presence of cracks);

- flooring the waterproofing membrane;

- installation of vertical guide profiles.

The fastening of the waterproofing membrane is produced outside the insulation with an adhesive of at least 10 cm. For reliable fixation and preventing the accumulation of condensate, use a special sealing tape.

Connection of profiles with support brackets is performed through the grooves. For their final fixation to the supporting structure, rivets are applied. The profile installation is carried out in such a way that it moves a little without any problems in the vertical plane at temperatures.

The correct installation of the insulation and the membrane is the key to high-quality installation of ventilated facades. If, after some time, the membrane will fail or the insulation will disappear, then this may lead to a decrease in the flow of air flows or the damage of heat-insulating material.

Installation plates

Fastening the fans of the ventilated facade can be carried out in two ways:

- open (used bellows);

- hidden (self-developed anchors apply).

The most common is the first option. This is explained by the fact that there are monsters of different shades on sale, which are similar to the color of the facing material. If you can not be able to purchase a bite of the necessary coloring, they can be painted in one color with a trim.

Installation of facade plates is carried out after a reliable fixation of all bells on the profile. All profiles are equipped with rubber seals. Filling material fastening starts from the bottom of the wall. Between the tiles is necessarily a small gap.

The installation of elements of the ventilated facade provides for simultaneous installation and other essential structures:

- drainage pipes;

- electrical wiring with lighting devices;

- mounts under the slopes, etc.

Some Soviets

To prevent errors that can lead to a reduction in the life of the skin and the wall itself, a number of rules must be adhered to:

- It is impossible to apply the technology of the ventilated facade for the facing of houses made from the hollow bricks and foam concrete blocks. Such a base is not very reliable for fastening the frame, which will cause the deformation of the structure.

- Before carrying out installation work, all fasteners are tested for strength.

- The deviation of the brackets from the horizontal surface level should not exceed 0.5 cm.

- After mounting the plates, the reliability of the new facade is checked. The trim should be stunned. The absence of a grincling and cod testify to the qualitatively done work.

Video on the installation technology of the ventilated facade: