Bordours are widely used in road construction and landscape design. The plot is discussed with their use acquires a neat and finished look. With the help of a curb, you can divide the space on the zone. And also to protect the flowerbed or track, which as a result of this design look more effectively. In addition, borders can be made by the most simple materials. For their production, form for a sidewalk border is applied. We will tell about all the subtleties of this process in this article.

Content

The need for use

Border stones contribute to the preservation of the integrity of the road surface and preventing the destruction of its edges. However, often factory products are quite expensive material. To reduce costs, you can purchase a special form. Independent manufacture of stones will cost significantly cheaper, because for this you need only sand, cement and water. From these components, the mixture is prepared, poured into the form and the result is a stone with high aesthetic indicators. In this case, it is possible to adjust its thickness.

The manufacture of a border with the help of forms has significant advantages. These products significantly simplify the technological process of production. The presence of a form allows you to make a border fence without the help of specialists. With this task, you can cope with your own even having experience.

Types of borders

Borders are divided into species depending on the purpose and material used in the production:

- According to the first criterion, the road, paving and garden border is distinguished.

- By material, it is divided into vibropressed, concrete and granite.

- The purpose of the road fence lies in the separation of the carriage and pedestrian part, pavingly - in protecting the coating. Garden fences are used both as decor and to strengthen garden tracks.

When designing a section by border stones, it should be remembered that the concrete material laid in the soil may disrupt the circulation of groundwater. To avoid this, stones should not be located too tight.

Varieties of form

Forms for borders are divided into three types depending on the material used in the production process. They are:

- wooden;

- steel;

- plastic.

The most popular are products from PVC and PE, as they differ in a long service life.

Plastic borders

Plastic curves are made on polypropylene borders. Used in the manufacture of road, pavement and main borders. Each form has the right geometric parameters and a glossy inner surface. These products have a number of benefits:

- Small weight and compact parameters give these forms universal qualities.

- With them you can work in various production conditions, this does not require special equipment.

- Plastic forms are widely used in large enterprises for concrete processing.

- Due to the presence of rigidity, the product is capable of withstanding heavy loads.

- The material from which the forms are made is quite elastic. This makes it possible to perform a platform and seal, while the integrity of the product is not violated.

- The lack of seams allows you to get stones with proper geometric parameters.

To maximize the operational period of plastic forms, some rules should be followed:

- Temperature indicators when stored should not be below 5 ° C.

- If the forms were in a lower temperature, they cannot be immediately used. Products must be placed on a day in a warm room, where the temperature level is 15 ° C and higher.

- Mechanical damage should also be avoided and the cement is only high quality.

Hardware

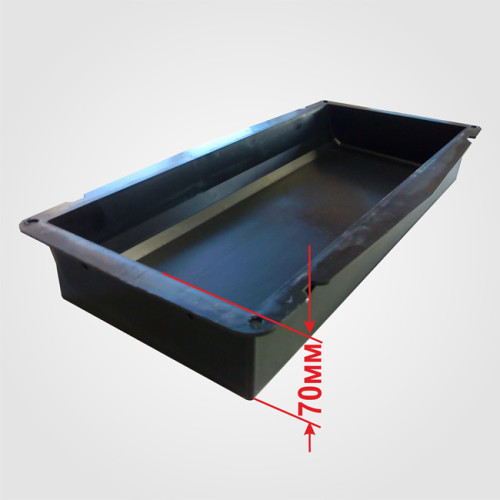

Metal forms are made on the basis of steel. In turn, they are divided into two types:

- fan;

- cassette.

Ferry type products have a pallet, four folding boards and trays that give the stone the required form. The mount of each section is carried out separately, it simplifies the process of the platform.

The cassette form is installed on the support frame. It contains special parts that seal concrete solution. The design has a pallet, folding boards and trays.

Form for border do it yourself

Form for the border can be made independently. This will require prepare such materials and tools:

- screws in the amount of 25 pieces;

- screwdriver;

- bars;

- metal sheet or plywood;

- board.

Features of work performance are reduced to such aspects:

- The work is performed on a flat surface covered with polyethylene.

- In order for the border to get smooth and without flaws, the board needs to be well handled.

- On the edges of the workpiece, cuts are made in which wooden or metal sheets are inserted.

- In the process of work, it is important to correctly determine the degrees of the angles so that the stone from this form gets smooth.

A shape for a garden curb can be made of wood or sheet metal. Consider both options. For wooden form you need to prepare:

- 4 bars 50x50 mm;

- slim steel sheet for brackets;

- screws;

- plywood or iron sheet.

The process is performed in such a sequence of actions:

- Bruks need to be copp in the form of a frame. To ensure their fixation in each pair of opposite bars, grooves are cut down.

- In places of connection with the help of screws, steel brackets are attached.

- The bottom is formed from the sheet of iron or plywood.

- The outer surface of the form is decorated with pebbles, rubble or pieces of ceramics. This material can be simply distributed for the bottom of the product. But for greater reliability it is recommended to attach these decorative elements to paper using water-soluble glue for this, and then put on the bottom. The paper should be below.

- Further, the cement composition is poured, after it is frozen, the form is removed. The sheet of paper is cleaned with warm water.

The metal garden form is manufactured as follows:

- The first thing from the galvanized metal sheet is needed to cut strips of 5 cm wide, the ends of which should be beaten with the help of a hammer.

- On this form is ready. For this purpose, iron hoops from the barrel can also be used if such material is available. This metal elements should simply be given the desired form.

Such products are quite simple to use. The border can be performed on any surface that will deepen the shape. Only stony foundation should be avoided.

Production of curbstone

Burgundy stones also perform the role of delimiters and are often used to design garden tracks, flower beds, paths, etc. The procedure for the manufacture of such products includes the following actions:

- The form is laid on the form and plunges with the help of a hammer.

- From the inside the product is extracted by a soil with a thickness of approximately 5 cm.

- As a result, a deepening is formed, which before work you need to richly moisten.

- The inner surface of the form is also wetting.

- Then the crushed stone layer or broken brick is poured into the product and the cement mixture is poured.

- When the solution is grabbing (this happens quickly, within a few minutes), the form is removed and applied again to create a new stone.

- This procedure must be repeated until the border is completed.

- It will take up to 3 days for its complete drying.

It is not recommended to perform this work at high temperatures, cracks may form on the stones. If there is a need to produce a border under such temperature conditions, it needs to be covered with a film.

Stencil form

The form for the manufacture of the border can be made in the form of a stencil. The procedure for working with such a design implies the following actions:

- It must be installed in a place where the future fence is planned to be placed, after which it is to fill with cement mortar.

- Using the spatula, the surface surface should be dissolved.

- After 30 minutes, the form is cleaned.

- So with the help of a stencil, a fence is fully formed. But the border will finally freeze only in a day.

Technology preparation of solution

To get a high-quality cement composition, it is necessary to use a grade of cement 400 or 500. Also need sand and water. To work, you should pick up a flat area without inclination. Further work occurs in such a sequence of actions:

- First, it is necessary to mix cement with sand, the resulting mixture must have a uniform color.

- The ratio of components depends on the cement brand. If the brand 400 is used, the sand must be taken in the amount of 3 parts. When using the brand 500 will need 4 parts.

- Then water is added to the mixture.

- It is important to determine the consistency correctly, because The qualitative composition must resemble a thick sour cream. If you wish, you can add additional components to the solution, such as a plasticizer or lubricant for the form.

- Cement composition, which has the first component, is more resistant to moisture. And the lubricant will easily remove the finished stones from the form.

- This mixture is ready, you can pour it into shape. In the course of this procedure, it is necessary to monitor that there are no air bubbles in the solution, otherwise the stone will turn off.

- After 2-3 hours, when the product freezes, it should be removed from the form. But in order for the stone to become quite strong, it will take another 24 hours.

- After that, you can proceed to the formation of border fence. Using one form, you can get several thousand units of curbstone.

Also, in the manufacture of decorative stone, pigments are added to the composition, which allow you to give the product the desired color. But these components must comply with certain requirements:

- Pigment substances that are resistant to an alkaline media, atmospheric precipitation and ultraviolet rays should be applied.

- Their content should not exceed 5% of the total mass of the solution.

- Adding an excessive amount of pigment substances will lead to a deterioration in the quality of stones, reduce their strength and resistance to low temperatures.

Conclusion

Forms allow you to make stones for sidewalk and garden fences, as well as for the decor of the territories. Independent production is more favorable in financial terms, and in terms of quality, the product is not inferior to stones manufactured by specialists. Forms can be made with your own hands. Materials that are required for this are quite affordable. And the technological process does not provide for complex actions.

The machine manufacturing technique using a form is shown in the video: