Monolithic bases of buildings are constructed with mandatory reinforcement. It is necessary to improve the strength of the foundation design. It is important to make the right selection of reinforcement for the foundation and the method of its connection.

Content

Types of reinforcement for foundation

Types of reinforcement for foundation: A division into two classes is made. For class A-I, the following is characteristic:

- used for foundations that do not experience stretching;

- has a smooth surface;

- armature cross section - round.

Reinforcement of such class fittings involves the installation of vertical and transverse rods.

Characteristics of class A-III fittings:

- can be used to build grounds experiencing stretching efforts;

- the surface of the reinforcement is equipped with ribs that improve the adhesion of concrete with its surface.

Note: The optimal fitting size for the foundation of the building weighing up to 50 tons - 6 mm in diameter (class A-I), for a heavier building - 8-10 mm (class A-III). Such fittings are produced in bays or in rods of 6.9 and 11.7 m.

A separate type includes plastic fittings for the foundation. It has the following advantages.

- Light weight, which is important for inter-storey floors.

- Not afraid of corrosion.

- Low thermal conductivity: no cold bridges are created.

Choosing materials for the foundation, you should consider the disadvantages of plastic reinforcement.

- Low resistance to tensile efforts. This reduces the effectiveness of reinforcement as an element that reins concrete.

- It can not be used for the construction of structures, the operation of which suggests high-temperature heating.

- There is no possibility of connecting reinforcement with welding.

- There is no possibility to give the rods the necessary form: plastic reinforcement bend on special equipment.

- The deterioration of the strength characteristics during operation due to the destructive effects of the alkaline medium (contained in cement solution).

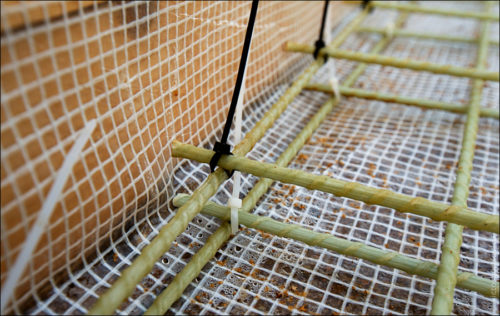

The plastic reinforcement connection is performed in two ways:

- with the help of burnt knitting wire, using a gun for mating or pliers;

- with the help of plastic clamps.

Moving reinforcement

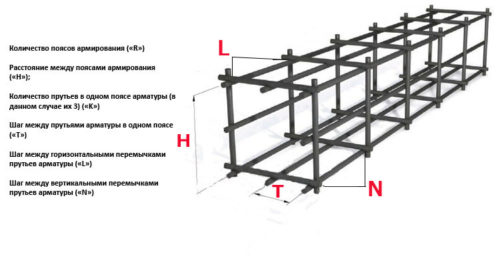

The fittings for the foundation must be mounted so that the result is a frame of several tiers of horizontal rods. They are connected with vertical any of the following ways.

Knitting rod of reinforcement

The assembly of reinforcement for the foundation is carried out by a special soft wire, which is cut into pieces of about 20 cm long. Wire diameter - 0.8 and 1.2 mm. Twisting it is performed by tools.

- Pliers: folded twice the wire twisted by several turns first manually, and then densely the planes.

- Knitting crochet.

- Traverse.

- Using clamps: For this, metal or plastic clamps are used. They are tightened at the site of intersection of horizontal and vertical rods.

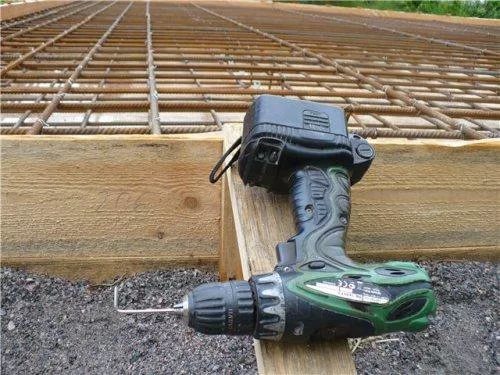

- Knitting pistol: The method involves the use of expensive equipment, which is cost-effective for significant volumes.

Important: Applying a connection method by clamps is possible if the builders will not go from the rods during the fill of the formwork concrete. Otherwise, the design of Armopoyas will be destroyed.

Manual fittings: General rules

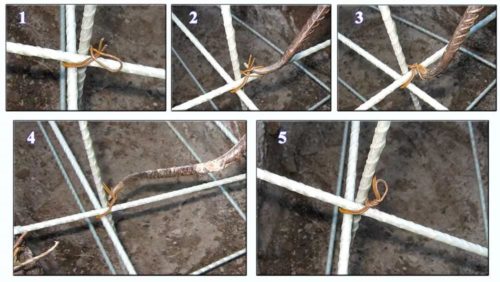

Using a hook of a special form is a simple and reliable way, with which plastic and metal fittings are connected for the foundation. The process provides for the following actions.

- Cut wire folded in half.

- Wire turns around around the intersection of the rod.

- The hook is inserted into the loop, and the other end of the wire is tied up around the sting tool.

- Rotate the hook tight twist the wire. The end of the wire during twisting hold hands.

- The hook is removed from the loop, the wires of the wire remove towards the frame.

During the installation of Pruhov, some rules are followed.

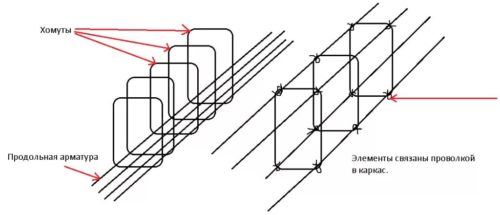

- One-line-oriented reinforcement is connected by the Vangest (see scheme). In this case, the length of the adhesion depends on the diameter of the rod (it should be 30 diameters).

- The optimal size of the square in the reinforcement frame is 250 × 250 mm.

- Wire can be replaced by plastic clamps.

The twisting method has an advantage over welding: the installation of reinforcement takes less time. The branches can be connected in the absence of the possibility of connecting to the power grid.

Methods of mating fittings

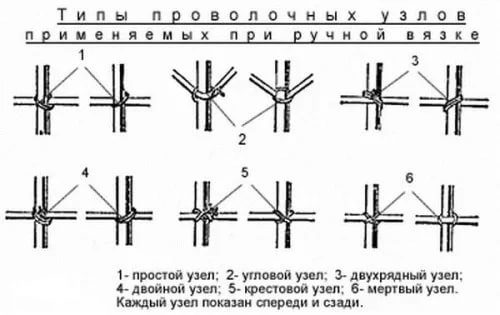

Before connecting the reinforcement, it is necessary to check the correctness of the installation of the rod. They must be laid vertically or horizontally. The structure of the reinforcement of the base consists of several (two or more) horizontal tiers supported by vertical elements. For a durable armature connection, several types of nodes use (shown in the diagram).

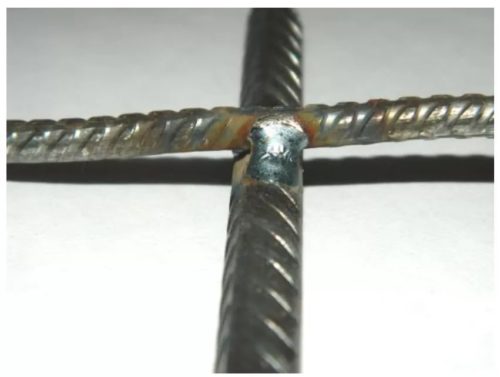

Connection of reinforcement welding

Welding fittings allows you to quickly and reliably connect it into a single frame. But this method, compared to the manual viscous, has a number of shortcomings:

- the characteristics of the metal in the reinforcement framework deteriorate, which affects the reliability of the base and the operation of the structure;

- when the concrete vibration shift, welding space can be destroyed;

- special equipment and skills are required.

Rules for calculating reinforcement for foundation

The calculation of fittings for the foundation is necessary to determine the amount of material and ensuring the strength of the structure. This takes into account the following.

- Corrugated reinforcement, compared with smooth, has greater strength and resistance to bending efforts. This quality affects the strength characteristics of the foundation.

- The rods must be at a distance of 20-30 mm from the walls of the formwork. This will prevent metal corrosion.

- In a multi-tier frame, smooth rods are located vertically, being a support for each tier.

Important: The design of the reinforcement frame depends on the size and mass of the built building. For example, at the base of the one-storey building, the rods are located at a distance of 0.5 m from each other, and the two-storey it is not to exceed 0.3 m.

At the end of the article on how the installation of reinforcement is performed for the foundation - video with explanations of some nuances.