Modern houses are impossible to imagine without heating. After all, the presence of heat in the building is a pledge of a comfortable stay in it. Today there are many types of boiler equipment for the house. All of them differ in characteristics and functionality. Next, we consider in more detail how to choose a boiler for the house, as well as get acquainted with the phased method of installing the heating equipment.

Content

Varieties of boilers for home

Most often in homes use the following heating equipment:

- Gas boiler for home. Most often installed in country cottages.

- Heating equipment is represented not only by gas systems. Recently, the popularity of boilers on liquid fuel, which burn fuel oil and diesel fuel are gaining. Although these aggregates are less environmentally friendly, but are an excellent alternative if there is no gas in the cottage settlement. When using such heating equipment, the homeowner will need to be thought out the location on its segment of the container for liquid fuel, as well as in order to take care of its reserves.

- If there is no gas and the ability to bring liquid fuel in the village, you can use heating equipment on solid fuel - anthracite, wood, coke or slate. True, the inconvenience of using such boilers is the impossibility of automatic fuel supply, which eliminates simple housing in the winter period. There are solid fuel boilers with automatic fuel supply, but they work on special pellets, granulated wood waste, which in our country has not yet been distributed.

- Alternatively, you can use biofuel and multi-fuel boilers that can work on several types of fuel. But the price of such aggregates, as well as their low efficiency, in comparison with monotocular boilers, does not allow them to conquer the interest of homeowners.

- There are other types of heating equipment: thermal pumps, eclectic convectors, etc. But while in our country they are rare.

It is worth saying that not only comfort in it, but also the safety of its tenants depends on the correct choice of heating equipment for the house. Consider in more detail the characteristics, functionality, pros and cons of various types of boilers for home.

Characteristics and principle of work boilers for home

Solid fuel boilers

As mentioned above, the heating of a private house is a solid-fuel boiler in the area where there is no gas, but there are large stocks of solid fuel: coal, wood, fuel briquettes. The use of such aggregates is not too convenient, however, in some regions they are economically more profitable than gas. Much popular because of the simplicity and low cost such as the type of installations purchased among dachensors.

The principle of operation of solid-fuel metal boilers for the house is based on burning solid fuel, which provides heating of the coolant. Basically, such installations are made of cast iron, less often from steel. Fuel for them can serve - firewood, coal, pellets, peat, etc. These aggregates are very convenient for heating small agricultural buildings.

Advantages of solid fuel boilers for home:

- Undoubted pluses of solid fuel boilers is the availability of fuel. Firewood or waste business wood is almost in any region in unlimited quantities.

- Such units are ideal for the heating of houses behind the villages, and to which it is economically inappropriate to lay the gas trail.

- Also, solid fuel installations can operate on various types of solid fuel: coal, wood, peat or wood briquettes. The heating of a private house with a coal boiler is perfect for residents of coal mining regions.

The main disadvantages of such heating devices is:

- their size

- the need to often make fuel bookmark,

- practically zero adjustability,

- the need to allocate a place to store fuel.

Mainly solid fuel boilers can be divided into two categories:

- one-window;

- double or pyrolysis.

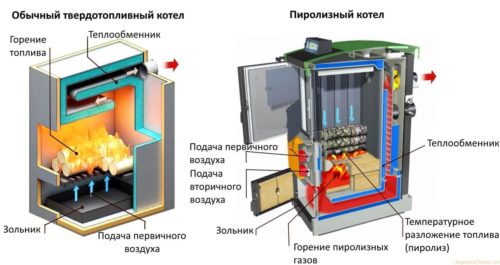

If the principle of operation of a single-first boiler is ultimately understood, then the method of functioning of the pyrolysis device is slightly different. Heat release in such an unit does not occur due to combustion of fuel, but due to the burning of pyrolysis gas. In the first furnace, wood fuel is heated without access of oxygen, while highlighting the pyrolysis gas that enters the second chamber and burns there at high temperatures. A distinctive feature of such a boiler is that the fuel laying can be made once a day. These units have a fairly good range of regulation from 25% to 100% of the installed capacity, and at the same time they are more economical. But these boilers have a significant disadvantage - the price, which is 3-4 times higher than in one-window units.

How to choose a solid fuel boiler:

- When choosing an aggregate, pay attention to what kind of fuel in it can be burned and what maximum power it produces.

- It will not be superfluous to learn what the CPD stated by the boiler.

If the heating system is updated, then it is better to provide the design and selection of equipment to professionals.

Gas boilers for a private house

The use of gas boilers is quite popular in the world. The availability of gas networks and a high degree of equipment automation allow you to minimize the participation of a person in the process of heating. Fuel for such boilers is clean, and does not pollute the boiler room, and also does not require cleaning of combustion products, like solid fuel boilers. Another indisputable plus of gas boilers is small overall dimensions with power comparable. The main fuel for such equipment is methane, however most models can work on propane, which makes them more versatile.

Electrocotels for a private house

Electrocotels for the heating of a private house are less popular among the inhabitants of our country. The principle of operation of such an aggregate is to heat the heat carrier by electric ten.

Its device is quite simple. In the housing of the boiler, a tank was installed with a tank, through which the liquid circulates thanks to the pump. Also, electric boilers are equipped with an automatic adjustment system, which is installed in the housing.

Pluses of electrocotel:

- The biggest advantage of this type of boiler is its environmental friendliness and safety.

- It can be put in any room, because it does not require supplying gas pipes and chimney installations.

- Such boilers are also very easily adjustable and can practically autonomously perform tasks.

Their disadvantage is a fairly high cost of electricity, as well as the limitation of electrical capacity, especially in old villages.

When choosing an electrocotel, it is better to pay attention to the models that are equipped with automatic regulation systems. The power of the unit should be determined at the rate of 1 kW per 10 m2 of the area.

Liquid fuel boilers

Liquid aggregates are rare in our homes. Their installation is unpopular due to the high cost of equipment and work. The work of such a boiler is based on the combustion of diesel fuel submitted under pressure, less often - fuel oil. Most of these aggregates, as well as gas, are two-circuit, which allows them to be used as a flow water heater.

Advantages:

- The undoubted advantage of such a boiler is its autonomy. All you need is a tank with diesel. At the same time, they have a high degree of automation and can for a long time to perform the task without human intervention.

- They are also much more eco-friendly solid fuel boilers and safer gas, which allows the installation of such equipment without a variety of permits.

The negative side of such devices is the high cost of diesel fuel. After all, at the heating of a house of 100 m2 per season, more tons of fuel may be required. In addition, it is necessary to install additional containers for it, which also need to warm up, because the fuel is thickening at a negative temperature.

Features of choice:

- The choice of such a boiler depends on the heated area.

- To select the power of the unit, you can simply multiply the area of \u200b\u200bthe room, where heating is planned, the coefficient of 0.1. In order to simplify the selection of the device, consult advice to those skilled in the art.

Combined boilers

Combined boilers are one of the best solutions for regions where frequent fuel interruptions occur. For example, it is often combined by gas and solid fuel boilers of long burning, as well as gas and liquid fuel units. Such equipment is more expensive, but it allows the user if necessary, it is easy to switch to a spare type of fuel.

The choice of the boiler depends on which fuel is more accessible in a particular region. Modern aggregates make it possible to damn private houses of any area with a high efficiency.

Instructions for installing boiler in the house

Technical requirements for the installation of a gas boiler

Before starting the installation of a gas boiler on its own, it is necessary to remember that the use of this equipment is associated with a certain danger:

- First, the fuel for this type of boilers is methane, which is dangerous for human life, so even the slightest gas leaks can create big problems.

- Secondly, in the process of burning fuel, carbon monoxide is formed, which should be excluded from the room without any problems. Even a small concentration in the air is enough to cause poisoning with sad consequences. That is why when installing the boiler should strictly fulfill all the requirements for this equipment.

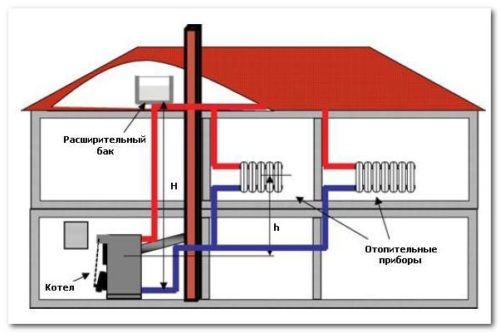

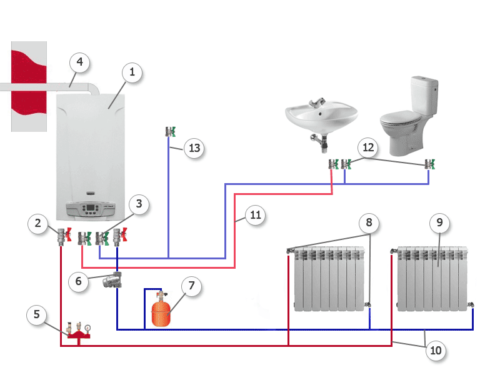

If the installation of the boiler and its strapping can be carried out independently, then its connection to the gas distribution network and commissioning work must be entrusted with certified specialists. Also, you should not try to independently mount a complex system in a big house. This requires knowledge in hydrodynamics and heat engineering. Improper wiring of pipes with coolant, radiators, the incorrect placement of the expansion tank can be unbalanced by the system, which will lead to an emergency.

Requirements for connecting gas boiler are presented as a chimney, and to the room in which the equipment will be installed:

- Thus, a chimney for discharge of exhaust gases from the boiler should not have more than three turns or bends. Its horizontal part should not be longer than 3 meters, and the distance from the flange portion to vertical boiler flue -. 0.25 m All of these standards are strictly checked, and their failure would entail serious penalty.

- Requirements for premises must also be strictly adhered to. Single-loop boiler (only for heating) can be installed in any home room except bathrooms and living rooms. Turbofan boiler (second circuit operates in the hot water supply) can not be installed in the kitchen. There is also a room requirements depend on the capacity of the boiler.

- Devices power up to 150 kW can be set on any floor, while the more powerful models - only on the first or ground. In addition, depending on the capacity and size of the boiler room. It is calculated by the formula S \u003d W * 0,2. The minimum height of the ceiling must be 2.5 m, and the minimum amount of space 15m 3, Irrespective of capacity.

- The room should be equipped with a natural light source (small window) in the opening window leaf and the door leaf with a width of not less than 0.8 m. Between the door and the floor should be a gap of at least 20 cm or vents installed. If the boiler is installed in the basement, it must be equipped with separate direct access to the street. The walls of the boiler must be lined with fire resistant material, and have a fire resistance of at least 45 minutes.

- The device is raised floors, suspended ceilings and niches in the boiler room are not allowed. For maintenance and repairs to the equipment must be provided with full access.

- It is mandatory the installation of ventilation systems.

Installation of floor and wall-mounted gas boilers with their hands

Before you begin work on the installation of the equipment, it is necessary to examine the scheme of its connection. It is better if the specific conditions of the project will be certified by the organization.

Installation of the boiler wall as follows:

- After selecting the place of installation wall portion, which will hang the boiler must be insulated with refractory material.

- Before installation, prepare a pot. The process of garbage collection can be collected in the water nozzles. It should be removed with water under pressure.

- Next, the water supply system is mounted. A shut-off crane, filter, and one more crane is connected to the boiler nozzle. Cranes are needed to close the water during filter replacement.

- Then the chimney is installed. Its diameter should strictly comply with the requirements of the boiler manufacturer. Over the rod of the roof, the upper part of the chimney should rise at least 50 cm.

- After mounting the chimney, it is proceeded by checking the thrust. Modern boilers are equipped with automation that checks the quality of thrust. In case of bad thrust, the boiler will not work.

- The heating circuit is connected.

- The next step is connected by gas supply. This is done using a special hose or steel pipe.

- Installation of an outdoor boiler differs from wall models The need to fill a separate foundation for it and laying refractory outdoor material.