The tape saw is a building tool that enjoys constant in demand in any building process due to its reliability. For the cutting of materials of different nature of origin, the canvas are widely used by this type. In order for the operation tool to be long, the choice is carried out, given the complex of suitable criteria.

Content

Ruler Saw Selection Rules

Pay attention to the criteria list below to find out the degree of utility of the tool to solve a specific task or for work in different directions:

- scale of work and regularity of their conduct;

- pouring saw;

- parameters of teeth;

- the dimensions of the canvas;

- sharpening quality;

- manufacturer.

Important! Take the decision only after a thorough check of a whole set of parameters, and not individual indicators. This will affect some parameters of the work performed hereinafter:

- equality of the cut line;

- the absence of cracks in the thickness of the reed sheet;

- degree of vibration;

- the absence of chips on the cut.

What kind of tape saws?

Several categories of tools using method for use:

- for stone;

- tape saw on wood;

- for metal cutting;

- for cutting synthetic materials.

Please note that for the canvases that are recommended to use in working with the materials of a more solid structure, it creates a strengthening by applying alloys of the maximum possible strength.

Important! Only some types of metals are used to produce the cutting element:

- composite alloys;

- steel;

- solid alloys.

Let us give an example for the metal tape saw. Given all the variety of natural ore and its alloys, when developing a model of the instrument take into account the variability of technical characteristics. Therefore, for a specific category of metals, use a specific type of tape saw:

- with the cutting of high carbon steels, pay attention to the tools of composite alloys, for example, M-51 brand;

- to cut the low and medium carbon steels, give preference to bimetallic canvases, for example, M-42 models;

- to qualitatively carry out the cutting materials of heat-resistant and wear-resistant for a long period, an excellent option - SP models;

- to work with products of increased hardness indicators, poorly refractable, inhomogeneous structure, such as products from titanium or nickel-based alloy, apply TST tool.

How to choose a tool, given the scope of work?

Before buying a ribbon saw, calculate the scale of the tasks:

- to use on industrial production with regular loads, a tape saw will be required, the price of which will be higher, as well as the strength indicators;

- for one-time or irregular use in domestic conditions, there is quite enough standard strength indicators.

Dimensions of the web

Parameters Width and saw length Select, based on the conditions for using a specific machine model. Title the instructions of the equipment and the selected cutting tool.

If there are no such indicators in the ribbon saw certificate, consider the following recommendations:

- the thin blade is deformed when working with gross billets;

- the wider the saw blade - the greater the cut;

- focus on the thickness of the sawn product - than it is less, the greater the likelihood of obtaining the deformed items after the end of operation using too thick saws;

- for figureless or contour cutting, correlate the width of the cutting part with the ability to cut the material at the desired angle.

Important! Currently, the width of the tools of this type varies from different manufacturers in the range from 14 to 80 mm. The rational solution will be the average rate of 38-41 mm.

How to choose suitable teeth parameters?

First, pay attention to the quantity. Pattern in this regard is simple:

- the greater the teeth, the better the material with thick walls was cut;

- fewer teeth reduces the load on the entire area of \u200b\u200bthe canvas;

- the voltage during sawing is evenly distributed on the entire surface of the ribbon saw with a large number of cutting edges.

Important! The number of teeth varies from 3 to 24 pieces in the tools of modern production.

The next stage is the choice of the type of teeth in size. Note the recommendations below:

- large teeth allow for deep propuls, for example, it is advisable to use them when treated with trees;

- the cutting edge of a small height is an excellent option for sawing thin-walled sheets.

The teeth pitch is another parameter, the size of which must necessarily match the response from the machine. Regarding more rational use, these requirements are allocated:

- a major permanent step Choose when molding a small sheet material of a small format;

- frequently uniform location of the teeth is a rational solution for the cutting of large cloth;

- a variable tooth perfectly copes with the task in the processing of soft material of various nature, while the rate of production increases due to the lack of clogging of the saw.

The divorce of the teeth affects not only the quality of the work performed, but also to the level of vibration, and accordingly the wear resistance of the tool. Distinguish the following types of cloths on this principle:

- A wavy profile apply in working with a thin material or with blanks of small sizes.

- Standard, in which all the elements of the cutting edge are located alternately in both directions, plus one tooth is in the center. Prefer this type of layout with the planned cutting of bulk parts, contour cutting or when installed on the vertical machine model.

- A variable or group is distinguished by the pairwise arrangement of the teeth to the right and left. Tools of this type are more expensive due to the fact that the efficiency of the result is higher, and the load on the cutting item itself is lower.

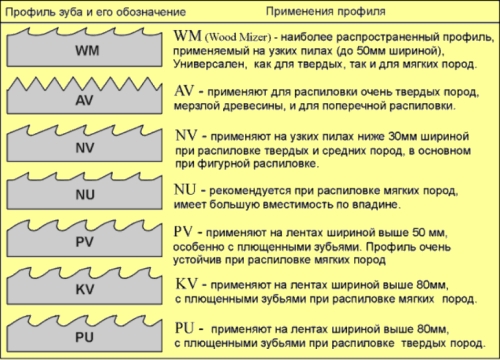

Pay attention also to the tooth profile. As an example, consider the applied table of the type most suitable under a certain breed in tape saws intended for cutting wood.

Sharpening quality

We pay very close attention to this criterion. Determine the quality of sharpening in this way:

- check the severity of the teeth;

- note the homogeneity of the material;

- check out the lip of the cutting edge line.

Important! In addition to identifying the quality of the canvas when buying, ask the supplier about the possibility of releasing, if necessary, how much the cycles of the cutting edge update are allowed for the specifically selected brand of the tape saw.

Review the video, the ribbon saws in which they rule and sharpen in order to more clearly imagine this process.

Manufacturer

Pay attention to the tool brand. To date, many companies are engaged in the production of tape saws, both domestic and foreign. If you preferred the expensive equipment imported manufacture, be sure to check the authenticity of the goods. Determine this will help quality certificates with all the necessary seals and labeling on the tool itself.

To find their way around the manifold, please note the following popular brands:

- Arntz (Germany). This company supplies its products to the market for more than 200 years. Today it is distinguished by a positive reputation, widely known worldwide. Branches are located in many countries, as well as service stations. The production shops of this company constantly control the quality of products of each party and regularly conduct research in the field of technologies and materials. Thanks to this approach, Arntz tape saws fully comply with all modern requirements. Special demand uses carbide canvases.

- Lenox (USA). Products of this company enjoys unpaid demand in the global market. Among the peculiarities of production, we note the application of the ARMOR's additional protective coating of the ARMOR, which is the basis of aluminum-titanium base. This ensures not only durability and high wear resistance, but allows for long-term uninterrupted operation in conditions of increased loads (for example, when cutting materials with large abrasiveness). In addition, the use of high speeds during the operation of the machine is not limited. The only nuance is all the Lenox canvases are distinguished by a well-founded high cost.

- Wikus. Another leading German world market leader. In addition to the multi-year practices for the manufacture of tape saws, we note another undeniable advantage of this brand - a variety of model range. Such an approach guarantees the possibility of choosing the most suitable tool for use in any projects, regardless of the scale of activity and diversity of directions.

- Forezienne (France). Among the peculiarities of the production of this company, we highlight the following facts. All tools are made of steel, the basis of which is enriched with ore. In the process of material formation, multiple process of hardening and vacation, hot and cold rolled products is performed. Due to this, the quality of the material that is based on the base of the ribbon saws, meets the highest cutting and strength characteristics.

- Lennartz (Germany). This firm is the largest manufacturer of tools for sawing various materials in Europe. More attention is paid to the supply of ribbon saws from composite alloys. Features of the technology are as follows: not only the very cutting canvas, but also the substrate in all models is made of high-strength steel, improved high degree of hardening. The gear edge is made separately from the high-speed steel and welded.

- Doall (USA). Despite the small size of the company, supplied by it products use permanent demand. This position is easily explained by the complete complex of high indicators of all important characteristics of tape saws. Through the use of high-strength steel, a clear compliance with all the rules of technology, the tools of this manufacturer are distinguished by a long period of use, regardless of the method of use and load. You can not lose sight of the choice of a suitable manufacturer and an impeccable DOALL reputation.

Conclusion

Pay attention to a very important nuance: the duration of the application is also affected by the correctness of the choice, and the appropriate application. Therefore, be sure to control the following working process conditions when using the belt saw:

- the correspondence of the cut material and the type of saw;

- suitable cutting speed;

- no overheating of the cutting part;

- tension saw;

- competent distribution for the tool of working time and recreation.