Flooring in the garage must meet certain standards: to be durable, withstand the weight of the car, to be immunity to the effects of chemicals ... Not all materials can be used to cover the floor in the garage. Tile is the most successful option for this purpose. From this article you will learn all about the varieties and methods of installing floor tiles for the garage.

Content

General characteristics

Most garages are built on a solid concrete basis. It can be both a ribbon foundation and a monolithic reinforced concrete plate. The "naked" concrete floor with active use will serve very long, especially if it comes to the garage.

Today in the garages use the following floor coverings:

- strengthening formulations for concrete;

- bulk polymer floors;

- cement strainer;

- tile;

- modular coatings.

We are interested in the last two varieties, since they are the most popular. This is quite simple - tiled materials easily and quickly mount, it can be done without training, the cost of most of them is quite small.

What are the requirements for outdoor garage tiles:

- It should be resistant to strong mechanical damage and loads.

- It should not be absorbed or deteriorated from accidentally spilled chemicals (diesel fuel, oil, gasoline).

- She should not burn or maintain burning.

- Tile care must be as simple as possible and quick.

- The tile on the floor in the garage is obliged to be hydrophobic, because it will be regularly exposed to wet.

- Durability is the last and most important requirement resulting from all of all of the above. Change the floors in the garage every few years - non-disabilities.

What materials do you have such characteristics? To arrange the floor in the garages, ceramic, clinker, sidewalk, rubber tile, as well as modular polyvinyl chloride coatings are used. Consider each of their materials in more detail.

Ceramic tile

The outdoor ceramic tile for the garage differs depending on the production method: Metlah, glazed and porcelain. The rest of the varieties consider no sense, since their cost is unable to high, and the characteristics are not suitable for use in the garage.

The advantages of the material:

- strength;

- durability;

- environmental friendliness;

- hydrophobicity;

- nonseasing;

- wear resistance;

- immunity to ultraviolet;

- frost resistance and resistance to the sharp difference in temperature;

- slip resistance (due to the presence of an abrasive substance or a special ribbed texture);

- high aesthetics;

- ease of installation;

- elemental care (enough sprinkle water);

- resistance to chemicals.

Metlah tile

At first glance, the Metlah tile makes the impression of very expensive and completely unsuitable for the garage - it is a pity to spin such beauty by wheels. But the Metlah tile is different, and you will immediately understand what we are talking about, if you remember how the outdoor coating looks like in the old entrances of the Soviet buildings. In those days, the Metlah tiles were used with housing construction for facing entrances, kitchens, bathrooms, with floor arrangement in public institutions, etc. At many metro stations, the durable brown or beige metlah tile has also been preserved, which indicates its extraordinary "survivability".

Metlah tiles made of burnt natural clay, in the outer layer, resistant to fading and a very durable dye is added. Previously, such a tile was produced in a limited color range - ocher, brown, beige, red, therefore used only for massive housing construction and did not use much popularity. Today, modern technologies allow us to use a solid foundation and apply an amazing beauty of drawings on it.

In Soviet times, the dimensions of the tile were standard: 10x10 cm, recently began to produce tiles 20x20 and even 30x30 cm. It is still not too expensive, therefore it is one of the best options for covering the floor in the garage. Before buying, it is recommended to immediately calculate the required number of items and, if possible, do without split parts, because the Metlah tiles is very difficult to cut the tiles, the more manual.

Glazed tile

This tile, like Metlah, is made of pressed clay, but the upper color layer is further burned. The effect of high temperature creates a smooth shiny surface with an even texture and high strength. Due to such glazing, the tile becomes durable and resistant to chemicals.

Under the glazed layer, any drawing or texture will be saved for a long time. The tile is easy to cut the tilewood, and even the beginner will cope with simple installation.

Unfortunately, the glazed tiles have a couple of serious flaws. The brilliant glossy layer over time is inevitably erased, but for the garage it is not so critical. The second point is the cost of such a tile is much higher than Metlah, however, it varies depending on the drawing, thickness and textures of the product, so if you need an ordinary durable and comfortable floor in the garage, you can choose an inexpensive practical option. For those who want to save and attach creative skills, you can buy a tiled battle that is worth the dear penny, and put an unusual mosaic floor in the garage.

Porcelain stoneware for garage

Porcelain stoneware is obtained as a result of presses and firing two types of clays - plastic irollite and durable caution. Initially, the porcelain tiles were used exclusively for finishing technical premises, but over time, its strength and durability was used in other areas of construction.

Porcelain stoneware is ideal for the garage floor - it meets all the necessary requirements and serves longer than any car. Excellent frost resistance allows you to use it not only indoors, but also outside, for example, for lays down the driveway to the garage.

The cost of the porcelain tile is much higher than that of Metlah or glazed, but if we consider the situation, looking into the future, the material will fully pay off and will even help save. To improve the floor in the garage, you can choose the most conventional tile without a picture or wisdom texture. The cost of such a product is about 500 p. For 1 square. m.

The only difficulty is to work with thick porcelain, you need special equipment that allows you to gently cut the tile. Ideally, it is recommended to purchase or rent a water-cooled machine, but as an alternative, you can use a grinder with cutting around the stone.

Installation of metlah tile

Today, fears in the garage are most often used in the garage of all the above types of ceramic tiles. For laying Metlah tiles, cement-sandy solution is required in proportion 1: 2 layer with a thickness of up to 10 mm. On the same solution, it is possible to lay and glazed tiles, but it is better to use the glue for this that can be bought with tiles. Such adhesive compositions have better adhesion to concrete base, and work easier and faster with them.

In the case of a porcelain tile, the glue should be used exclusively, and especially for porcelain stoneware. The cost of such adhesive is higher than that of the usual tile, but it is more durable.

Clinker tile

Clinker tiles are known for its durability and low cost. It is ideal not only to cover the floor in the garage, but also to create an access road, laying the floor on the terrace, etc.

There are several types of clinker tiles, each of which has its operational characteristics. We are interested in floor tiles with a maximum strength limit and bending strength. These two concepts serve as defining factors when choosing tiles on the floor to the garage.

The size of the strength is affected by the size and thickness of the product. This indicator determines the maximum allowable force that can lead to the destruction of the tile. The strength to bend depends on the water absorption of the product - the lower, the higher the resistance indicator for the bending. Based on these data, clinker tiles are divided into classes and brands.

What factors should be paid when choosing a garage clinker tile:

- Hardness - the higher, the better. The hardness is detected on the MOOS scale consisting of 10 natural minerals placed as the strength of the strength: talc, gypsum, calcite, fluorite, apatite, field swap, quartz, topaz, corundum and the most durable of well-known minerals - diamond. In the characteristics of the clinker plate there must be a number corresponding to the sequence number of the mineral, the hardness of which it corresponds. For example, if there is no number 1, then the tile is very continuing and is suitable only for decorative finishes. But the products with numbers from 7 and above can already be used in the garage.

- Wear resistance - clinker tiles are assigned abrasion classes from 1 to 5. The higher the class, especially the wear-resistant tile. Products 2 and 3 classes are suitable for home and small office, 4 - for public premises, and for the garage you can only use the tile of the 5th grade.

- Frost resistance - this indicator is also indicated in the numerical equivalent, and the higher the figure, the more frost-resistant tiles. These properties are closely connected with the porosity of the material structure - in less porous tile, frost resistance will be higher. For the garage it is better to buy extruded tiles, not pressed.

- Water absorption - this indicator also depends on the porosity of the tile. As in the case of frost resistance, it is better to choose an extruded clinker, since it is characterized by low water absorption indicators due to the extremely dense structure obtained as a result of high-temperature firing.

- Resistance to chemicals - depending on the degree of resistance to the effects of chemicals, the tile is assigned the corresponding class. The AA class means high resistance without external and internal changes of the material, but are small changes that do not affect the characteristics of the tile. Only these two classes are suitable for use in the garage. In rare cases, you can use tile class V.

Installation of clinker tile

Clinker tile must be laid on the prepared concrete base. It must be as smooth and durable as possible, without cracks, emptiness and sticking fasteners. Before laying the surface should be discussed, remove oil residues, paints, mastic, etc. If you want to align the base with the repair plaster, it is necessary to do it 3 days before laying the tile.

The moisture content of the concrete base should not exceed 4%, and age is more than 3 months. For laying, a classic mortar of 3 parts of sand and 1 part of cement M-500 is used. The solution is applied as evenly as possible with a layer of about 3 cm with a thickness of about 3 cm, after which they are aligned with the rail. Then a few cement powder is low, a slight cement powder is powder, so that he takes the extra moisture. Only after that you can lay the tile. After gluing the slabs, they should be moistened with water and cover with polyethylene until the solution is solved.

To work, you will need the following tools:

- building level;

- bulgarian with a stone disk,

- toothed spatula with teeth 5-8 mm;

- wooden rail 50-100 cm long.

Specificity styling:

- Remove the fabric packaging tiles and beat it to eliminate the color differences.

- To get a perfectly smooth seam line, focus on the directions of the grooves on the back of the tiles. The width of the seam does not have to exceed 12 mm.

- The concrete base is recommended to be pre-aligned with a cement screed with a thickness of at least 2 cm, but not thicker 4 cm. Ideally, the screed should be strengthened by the reinforcing grid.

- Before laying, the base surface should be primed by deeply identifying compositions to increase the adhesive abilities of materials.

- Before laying, mark the central axial lines of the garage space - it will help to smoothly put the tile.

- Apply glue or solution with small portions on the base, moving into a toothed spatula. Make sure that there are no non-registered areas. If you are convenient to apply the composition on the tile, the principled difference will not be.

- Align the tile and check it with the construction level.

- The seams are formed by conventional crosses with the desired width. The adhesive solution should not fall into the seams. If it happened, you can immediately clean the space. Slit seams should only be completely frozen the solution. At the same time, the grout must have high performance characteristics - to be resistant to water, chemicals, etc.

- Fill the seams by grouting, using the rubber spatula. To form the ideal structure of the seam, spend the grout into 2 approaches. After removing excess grouts, wipe the tile with a damp cloth.

Rubber tile

Rubber tile is made of fractional rubber crumb obtained as a result of the processing of old car tires. Since only high-quality rubber, natural and synthetic rubber and various fillers are used in tire production, one can safely talk about the same high quality of rubber tiles. In fact, it is difficult to imagine a more perfect flooring for the floor in the garage than a rubber tile, because in fact it is done for cars from old cars, representing perfect waste-free production.

Such tiled rubber has all the necessary qualities - it is durable, elastic, waterproof and durable. Moreover, it is immune to acids and alkalis, it is easy to wash and has an attractive appearance.

Rubber garage tile is more convenient than solid coatings. Often, car owners have to lie under the car for hours, turning out parts under the body, and on rubber, unlike porcelain book or ceramics, it is impossible to freeze, and it is much softer. In winter, tires gives the best clutch with shoes and does not allow slipping than other materials cannot boast.

Rubber tiles perfectly absorbs noise and can be used not only as an additional insulation and moisture protection, but also for high-quality sound insulation. We are very simple to transport and store material, and the cost of this is minimized. Over time, the tile does not seek and not deform. According to the statements of most manufacturers, the service life of the rubber tile with due laying is inorganized.

Installation of rubber tile

How can the rubber tile should be put so that it serves as a whole eternity? Be sure to align the surface. It can be like a concrete screed, so ordinary soil or asphalt. In any case, there must be a minimum bias for outflow of water and sides around the perimeter of the floor for additional fixation of the coating.

Mounting specificity:

- If you purchased a tile of less than 3 cm thick, it is recommended to lay out on a solid basis. Thicker products can be put on any surface, the main thing is that it is smooth and stable.

- Make styling the elements of the rows of flat line or with a displacement. Some types of tiles are already available with a ready-made lock connection.

- Rubber tile can be easily cut with a knife if necessary.

- Use polyurethane glue or bitumen mastics for gluing.

- Rubber tile does not require much care - it is enough to pour it with water from the hose or rub a soft brush.

Paving tile

Paving tiles can be an excellent flooring for the garage. For high-quality laying, it is necessary to correctly calculate the bias and organize a reliable basis.

The paving slabs possesses a good anti-slip effect, it is durable and able to withstand the weight of even trucks. It is almost no need to care for such a surface, except from time to time sweeping and washed from the hose. You can make the floor from paving slabs in the garage, even without professional skills and in a short time.

However, this material has a significant drawback - the porous structure of the tile perfectly absorbs different liquids, so if gasoline or oil shedding on it, the stain will remain.

Installation of paving slabs

Before mounting the paving slabs, it is necessary to provide a minimum base of the floor base in the garage for water outflow. It should be 1.5-2% or 1.5-2 cm per 1 m. You will practically not feel the tilt, but water, obeying the laws of physics, will quickly leave.

Styling features:

- Start laying the tile from a long corner, moving towards the exit.

- Try to put the tile so that it does not have to be cut.

- First, set the beacons by placing them in the corners of the garage (ordinary metal rods or tile pieces).

- To obtain smooth levels, use the thread and construction level by pulling the thread between the beacons.

- You can lay the tile on concrete or to the ground (clean from the garbage and remove the fertile layer of the soil of 10 cm).

- If you put it on the ground, you will wake it up with a vibropilet, float with rubble or screening, after which I will confuse again to eliminate the formation of voids.

- Fill the sand pillow cement tie, align it with rails, corners or pipes. To quickly and easily align the cement layer, go through a smooth bar.

- Align the whole area is immediately optional - you can do it as the paving slaves.

- All communications must be located under the paving slabs.

- Detailed video instructions for laying paving slabs will help you do work without errors:

- After laying, set the seams with a cement-sandy dry mixture.

- It is recommended to go through the surface of vibrotambovka, if there is such a thing, and adjust the knocked elements.

- Pour the surface from the hose with a spray nozzle so that it fixes faster. Repeat several times a day as you dry 2-3 days in a row.

Modular PVC coatings

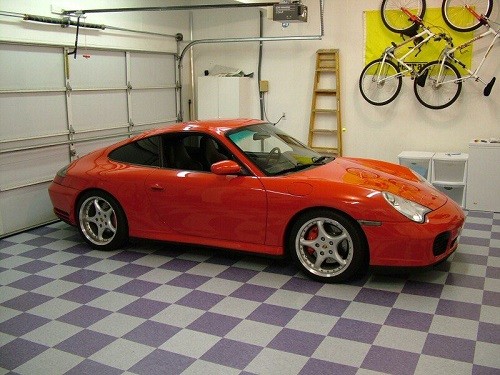

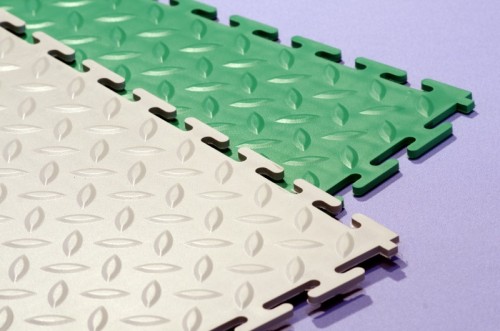

The last type of tile coating for the garage is modular PVC panels. They are made of polyvinyl chloride mass, immune to chemicals, burning, reinforcement, etc. Because of its high resistance to abrasion and the durability of PVC coverage, the coverage is actively used at airports, garages, metro, residential and office space. In fact, it is almost eternal and very comfortable material for flooring.

Plate thickness can vary from 1.5 mm to 7 mm and more. Thick 6-7 mm plates can be used even for cargo transport and aircraft garages. They are able to withstand the load up to 30 tons per square. m.

Installation of PVC plates is a separate topic and one of the main advantages of the material. Elements are attached to each other by means of T-shaped locks, "swallow tail" or hidden locks that give impeccable fixation.

The advantages of the material:

- strength and durability (perhaps even eternity);

- soundproofing;

- absorption of vibration;

- reducing dust formation;

- frost resistance;

- the possibility of temporary use (if necessary, the floor can be disassembled and collected elsewhere);

- do not require a specially prepared foundation. Even if we put them on the wet floor with cracks and potholes, they will retain their performance characteristics;

- PVC stove is almost impossible to break, split or spoil somehow, but if it succeeded, it is enough to replace only one segment.

- Plates are not lit and do not support burning.

Of all the above tiled materials for flooring in the garage, rubber and polyvinyl chloride are most popular, since they create the most strong and practically eternal coating. Their cost is higher than that of other materials, but in the long run, obvious savings are revealed.