To date, indirect heating boiler is one of the best options for a private house or garden with hot water and heat in the right quantity. And using it will cost you much cheaper than the flow heater. Although we will not deny that its value is much higher. But you can be sure that the equipment itself is fully justified. But it is quite clear that laying out a certain amount of money for the equipment itself, you want to save on the installation. So we'll now how to manually install a boiler, without involving expensive experts.

Content

boiler device and selection of equipment

In order to properly install the equipment that you need to fully understand how it is constructed and what its main features. Indirect heating boiler, in fact, represents a storage capacitance in a cylindrical shape, which insulated from the external environment, which allows to effectively use it even at fairly low temperatures. Inside additionally installed heat exchanger. This ensures the best heat saving.

In order to properly choose and buy a suitable boiler of indirect heating, some factors should be taken into account. The most important thing is its volume. It should be chosen, given how many tenants in the house consume hot water, at what time you need more water and how much permissaries are allowed.

If you calculate it difficult, take approximately 80 liters per ten. Today the choice is quite wide: from 200 to 1500 liters. But consider that a large amount is an additional energy overrun. Yes, and the device itself is more expensive with a large volume. If there is no need for big litter - do not overpay.

Pay attention to the quality of thermal insulation. It must be from mineral wool or polyurethane foam. Well for many criteria has proven a boiler of indirect heating DRAZISE. But I will not deny that the domestic boilers have proven themselves worse than overseas analogues.

But let's say that you have already chosen a suitable model, brought to the place of installation and just do not know what to do next. Further, your task is to correctly connect the boiler of indirect heating in the house.

Tools for work:

- distribution manifolds;

- hydraulic arrows;

- balancing valves;

- check valves;

- three-way valve;

- connection scheme;

- perforator or electric drill;

- screwdriver;

- roulette;

- valve for discharge pressure;

- protective glasses and gloves.

Connection diagram and main difficulties

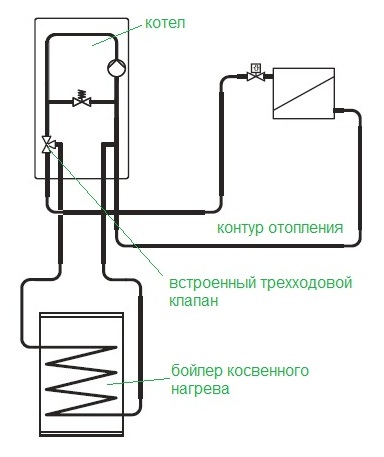

First, if you decide to install an indirect heating boiler, you need to use a boiler in which there is a special contour for it. They have one heat exchanger, and inside there is a three-way valve, switching the direction of the coolant flow or through the boiler itself, or through the heating system.

In fact, the connection of the boiler is the usual clip in your water supply system. The main task is to provide him with the influx of water in the right amount. Your attention is proposed a standard scheme for connecting an indirect heating boiler, suitable for most cases.

First, connect it with the water supply, and then with the power grid. Please note that there must be a ground socket next to it, because such devices are usually equipped with EuroShweples. Next, follow our instructions.

Connecting a cumulative water heater:

- Consider that the equipment is rather heavy, so before installing, make sure that the wall is quite strong. Remember that it will be held not only the water heater itself, but also the volume of water that enters the boiler.

- With the help of a roulette, measure where the points will be where you are hiding the equipment. Mark them with a pencil, not to make a mistake. The holes for the dowels are best drilled by a perforator. You can use the usual drill, but it is less convenient.

Important! Consider not only the distance between the anchors, but also the distance to the ceiling. If you drill holes back and too high - just you can not wear a boiler for hooks.

Water pipes:

- Do in advance in the pipes outputs for the boiler. Connect them with flexible hoses. Do not confuse. The entrance for cold water is marked in blue.

- This also needs to attach a pressure relief valve. There are cases when it is not included. Then you need to buy it. We also recommend mounting the tee to which the hose joins. This will allow you to drain water from the water heater without any problems during maintenance.

- Mandatory how to seal all the connections. To do this, you can use FMU tapes or pacles with paste. Give sealants as you should grab and only then proceed to the next step.

- After that, you can screw the crane of hot water. It connects to a special output on the machine. When you do it, unscrew the crane. First go air, and behind it and water. We advise you to unscrew the crane slowly, if you suddenly did something wrong. At this time, carefully examine all the connections and see if there was no leak. Consider that the strapping must be connected to the contour of heating and to water supply. If you connect it to the water pipeline, then you need to serve cold water into the lower part of the tank, and hot - in the upper one. At the same time, the recircular point is strictly in the middle. Only when the water supply is connected, and you see that there are no leaks, you can proceed to the power supply.

Circuit:

- To begin with, connect the equipment to the distribution panel. If there is no such possibility, the socket is suitable. Consider that we only connect the boiler at this stage. The socket is performed under the capacity of 3.5 kW, and at least 2 kW is required to operate the device. If you connect to the shield, determine where the zero phase and ground is located. From the shield, swipe the cable to the boiler. Do not connect yet. Let lies beside.

- On the side of the boiler, install the shield, close the machine and skip the cable. Pay attention to colors: yellow-green is grounding, red - phase, blue - zero.

- Cut about 10 centimeters of isolation from the cable, cut and talk the phase. After that, you can connect it with the terminals of the machine. Next, screw down the phase from the device, and from above - from the electrical tailor.

- Now you can serve electricity. Please note whether the work indicator caught fire. If not, it means that you have made incorrectly. Disconnect the current and recheck.

- Take the instruction and accurately adjust the temperature regime.

If all items you do correctly and in accordance with the instructions, the boiler is ready for fully. As you can see, you don't have additional skills. But be careful. You work with water and electricity, and this is a dangerous tandem.

Exceptions and features of other connection schemes

Four key schemes can be distinguished:

- Three-way channel. It is suitable for wall technology. In this case, you will need to use the chirurative pump and the expansion tank in addition to the specified steps.

- Two-axis scheme. In comparison with the standard connection there is one important disadvantage. You will have to turn off the heating in the house from time to time, because water heating stops after reaching the desired temperature.

- The dual-circuit boiler of indirect heating also has features of the connection. In this case, you will need to take instructions and adjust the valves of the system as accurately as possible. But this connection is only needed if you have several heating devices in the house. The scheme is infrequently applied.

- Hydraulic manifold. The boiler is connected in this case through the arrow. Such a scheme is generally used extremely rare, because it is suitable if the heating equipment simultaneously feeds the main heating and the "warm floor" system. The boiler in this case also connects to the hydraulic arrow.

We do not deepen into these four schemes, because the scope of their use is quite narrow. In most cases, the ideal option is described above.

The last thing we focus on your attention is a gas boiler of indirect heating, which is also quite common among water heating techniques. If you install an electric boiler, then with the task you can easily cope on your own. But for installing a gas boiler, you must have high-quality knowledge and skills of work. An independent connection of such equipment is categorically prohibited! It must be performed by a qualified specialist who has a formal license for such work. Otherwise, you risk your own health and life. Be careful.