One of the most popular materials for finishing walls and gender is a ceramic tile. Many craftsmen carry out her hand styling. When creating a wall or floor covering in most cases, it is not necessary to do without cutting tiles. To do this, you can use various methods - the most suitable option can be chosen according to the planned volumes and complexity of work, taking into account the existing fixtures for cutting, as well as the estimated cost of purchased tools.

Content

Tile preparation

If you plan to cut the tile for the first time, it is recommended to prepare material with a small margin. To master the technology of cutting tiles at home is not very difficult, you will need to choose suitable tools and master some nuances of working with this material. Prior to the start of facing work, we should sort the available material stock. The manufacturing technology (method of high-temperature firing) of the ceramic tile allows some deviations from the claimed size, the thickness of the products, as well as their shades. Separate tiles can be slightly different in length and width.

The same products are placed in stacks, sorting in size. As a template for measurements, a crusade with an applied scale can be used, chocked out of the perpendicular wooden bars of a certain length, as well as a ruler. After applying the layout of the future tile coating, it is recommended to decompose the tile on a free surface with cross-shutters to modify the laying. At the same time, it is necessary to thoroughly align the rows vertically and diagonally, observing the required symmetry and the necessary ornament. Thus, you will receive an idea how much tiles and how to cut.

The chopped ceramic tile is most often used as follows - laid along the extreme row of the coating, in the corners, places of laying of communications, as well as for the manufacture of complex facing patterns, ornaments and panels.

Features of cutting ceramic tiles

The tile is made of burned clay coated with a layer of baked glaze. As a result, the tile is characterized by a solid glossy surface, is characterized by strength, not subject to deformations, but at the same time quite fragile on the break and can easily split under mechanical effects.

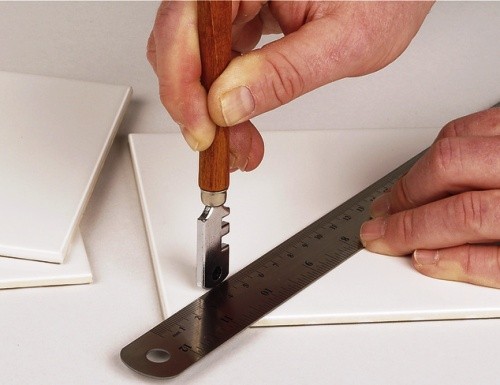

Placing the tile under the cutting is necessary on the front side by a construction pencil, or a conventional soft pencil or marker. After marking, you can perform a cutting tile, for subsequent high-quality laying, it is required to get a smooth and neat cut.

There are two basic methods of cutting ceramic tiles:

- make a sufficiently deep incision with the help of special tools along the lines marked and it should be carefully broken down tiles. In this case, an even incision will be performed from above, and the irregularities of the fault at the base of the tile will be hidden using a solution;

- with the help of a diamond disk, cut the tile on parts of the required form - this method allows you to get a sufficiently smooth cut without errors.

It should be borne in mind that the tile is recommended at a distance of at least 1 cm from the edge, with the help of a single outbreak. The cutting of the baccoon or on the electric stoveture-plate should be performed strictly on a flat surface, without a separation from it, otherwise the likelihood of the appearance of curvatures and chips is large (if the disc is stuck). In order to avoid the appearance of burrs, scratches and chips, it is necessary to ensure that the pressure on the tile under the cut is uniformly distributed.

You can break the tile by placing it on a flat surface using the following ways:

- having stopped according to the end line to the edge of the table, with force to press on the protruding edge of the tile;

- downstairs under the tile, respectively cut out of the groove, put a match (or a small nail), and click with the force on both adjacent sides;

- taking a tile for both edges, with force to hit the bottom of the rib on the rib;

- thin outcropped strips are shaped with forceps, as well as pliers, ticks;

- after overlooking it with notches (this method is applied to cutting outdoor tiles) - on the product carry it line, make notches with a sharp edge of the hammer. At the edges of the line should be made in-depth nottes. The tile prepared in this way is placed on a knee, covered with a dense cloth or felt, dried on top along the line with a hammer - as a result of the manipulations of the tiles, the tile is cleaned over the intended line.

For cutting of embossed ceramic and porcelain tiles (according to production technology, such a tile is distinguished by a special strength, as it is baked over the entire surface), use tools equipped with disks with a "diamond" spraying - the data of the tile varieties must be cut throughout the thickness. For the most efficient cutting of the tile, it is recommended to pre-soak it in the container with water for 40 minutes.

Tile cutting tools

Choose than cutting ceramic tiles, follows from the volume of work, thickness and density of the material.

Cutting tiles can be performed using the following tools:

- roller glass cutter;

- manual stationary tiles;

- portable electric stoveturis;

- tongs-tongs;

- bulgarians with dryorese (cut-off disk without slots with "diamond spraying").

With small amounts of work on cutting tiles (if you need to process several pieces) it is possible to use the glass cutter.

For processing more than a dozen tiles, it is recommended to use tiles. Due to the larger diameter of the wheel, the tiles allows you to perform a deeper incision, moreover, it provides a convenient handle, as well as a device intended for fault tiles along the cut line.

The wall ceramic tile is conveniently chopped with glass cutter and manual stoveturis, for cutting a more dense floor ceramic material, it is advisable to use electric stoves - with it, you can increase the accuracy of cutting, as well as reduce the waste of tile material.

Application of glass cutting

The glass cutter may well come in handy as the most primitive fixture for cutting a wall thickness of a small thickness. Using a ruler or angle pressed to the tile, glass cutter need to make an incision, conducting a wheel according to the markup (towards yourself). After that, you can neatly break the tile along the resulting groove.

Cut into a thick tiled and tougher floor tile in this way it is unlikely to work out, more powerful tools and fixtures will be required to process porcelain tiles.

Tile cut tiles

With the help of special tile tongs, you can cut a small amount of tiles. This tool is distinguished by low cost and convenient to operate, is used for simple cuts.

First you need to apply markup on the tile and carry out a special circle installed on the tongs. In this way, you can get a deeper groove than using glass cutters - therefore, the tile fault line will be quite smooth and smooth. The lips of the forceps need to be placed on the tile, so that the wide part, forming a small angle, turned out to be from above, and the central part is opposite the end-made. Gently squeezing with forceps, part of the tiles gently shake along the grooves.

For cutting thin strips of tile tiles use not very convenient, in this case it is recommended to use more complex devices.

Use of mechanical slabcoresis

The manual tile machine is equipped with a special major wheel for a deep outbreak, as well as a special mechanism that allows for a rift of tiles. Such a tool is very convenient for use at home, as well as popular among professionals. With the help of manual slab, it is easy to make cutting of significant amounts of tiles, including material of a significant thickness and durable ceramics.

For processing ceramic tiles, the following technology is applied by manual stovetur:

- it is necessary to arrange the tile on the surface of the bed so that the line of movement of the wheel coincides with the markup, and gently produce a single incision, while the push force must be poisoned so as to make the grooves sufficient for the flow of depth;

- after that, the tile cutting handle is translated into the condition active for a break, so that then quickly confident by pressing it to make a spill along the cut line.

To carry out high-quality tile processing, it is necessary that the width of the cut strips was at least 10 mm.

For efficient operation of manual slab cutter, you must track the following points:

- pay attention to the stability and rigidity of the base of the tile cutter, the thickness of the guides. Take a sample of the tile with you to the store, which you plan to cut and test the tool;

- it is necessary that the carriage moves smoothly without jerks (in the design of mechanical tiles, this requirement is implemented using a specially installed bearing);

- in the course of operation, it is necessary that the cutting "diamond" wheel was correct shape and easily scrolled (with the wear of the roller, the rounding of the acute edge, the presence of chips on the surface requires its replacement);

- the bed must be smooth, its surface is clean;

- there should be no mechanical damage on the handle.

To facilitate the process of cutting and faults of the tile with a stoveture, it is desirable to pre-dock it in water, as well as before cutting, add the machine oil drop over the line. After purchasing the minimum skills of using the tool with it, it is realistic to treat significant volumes of tiled material.

Cutting electric stovetur

For large amounts of work, it is advisable to use electric tiles, such devices can be purchased, as well as rent. Such a tile cutting machine is used by professionals, it is easy to perform various necessary operations. Technology cutting on large diamond disc revisions allows you to get the highest quality results. In this way, it is possible to give a tiled material with almost any form, including cutting the tiles at an angle of 45 ° (in order to avoid the appearance of the chipping, the sliced \u200b\u200bpart should not reach the edge of the tile - this section is grinding manually using a bar covered with sandpaper or on a grinding circle ). When processing the material with electric stovetures, a flat accurate slice with rounded edges is obtained (unlike manual tools that cut tiles on fragments with sharp edges).

The use of electric stoveturisses is characterized by a number of benefits:

- excellent tile cutting capacity;

- lack of dust, especially in case of cutting tiles with water supply to the cut line;

- obtaining a smooth and smooth cut of a tula material without special time and physical costs.

Cutting tiles Bulgarian

With the help of a grinder with a diamond circle, you can cut the tile of any shape. This method has its drawbacks:

- depending on the accuracy of execution, you can get tiled sections of various quality, not always smooth and smooth - the likelihood of the appearance of teeth is large;

- cut tiles can crumble.

It is recommended to carry out such works on the street, since a significant amount of dust is formed when working with the grinder.

Figured tile cutting

Often it is necessary to make a curly cutting of the tile - cut it in a different way, including at an angle, or cut holes. You can give a tiled material with a variety of forms using an electric machine, as well as using manual tongs - sequentially cutting off on a piece of tiles according to the pre-applied markup. For the formation of smooth ends, sanding with sandpaper or supfil is used.

After applying the electric stoveture, you can slightly correct the shape of the products with manual tongs.