The facade finish is the final stage of construction work, when the internal decoration of the cottage has already been completed. At the same time, it is one of the most important steps, because from how efficiently it will be performed, the appearance of the structure depends. A large number of finishing methods of facades opens up ample opportunities to designers and builders. Thanks to which the house will not only look beautiful, but also have excellent performance, including energy efficiency.

Content

Types of finish facades

In order to choose the method of finishing a cottage, you need to know the main directions in this case and what materials are used in the work of work. It is important to understand all the strengths and weaknesses of each method to make the most successful choice.

Before designing the finishing of the facade of the building, it is important to take into account one point -

how will the country house be operated. If you do not plan to live in it in the cold season, then carry out insulation of the facade just does not make sense, since these works are rather expensive both in terms of the cost of materials, and the price of the work.

So, below, we list the most popular methods of facades:

Plaster. One of the oldest and to date current types of finishes of the outer surfaces of the walls. As a rule, the plaster is nothing but the preparation of walls to staining. The task of this work is to create a monolithic, homogeneous and smooth wall surface. Most often use cement plaster and gypsum. The first is a cheaper option, but loses to the gypsum coating in terms of durability. Gypsum-based mixtures have a greater plasticity, have excellent clutch with the surface. Such plasters are perfectly passed by air, making the facade is more ventilated, which prevents moisture accumulation on the wall surface, preventing the appearance of fungus and rotting materials. The dignity of this method can include monolithium and durability of the resulting surface, which can reach 25 years. From the shortcomings it is worth allocating that most of the work on the plaster are carried out manually, which significantly slows down the process of execution.

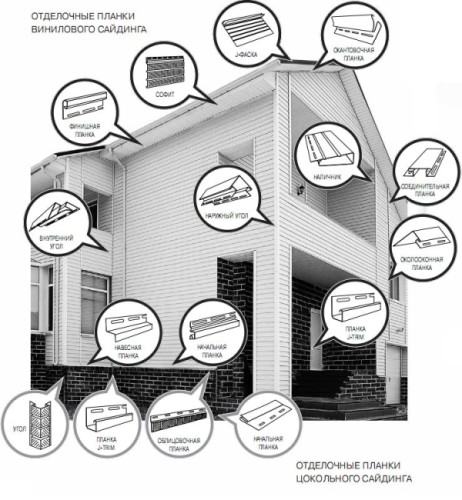

Siding. One of the most modern methods of finishing the facade. Thanks to its excellent performance and ease of installation, Siding quickly gained popularity among builders. This material is a few species:

- Vinyl or PVC.

- Metal (made of steel, aluminum or copper).

- Wood.

- Cement - This type of siding is used for the foundation.

Siding is very easy to install. During the work of work, the presence of a special tool is not required, and the ease of material allows you to mock it manually. Siding panels have special locks in the ends, which facilitates the installation process. Processed by special solutions, the material perfectly transfers contact with water and solar rays, is not subject to corrosion and rotting, almost does not absorb moisture. The panels are perfectly passing the air, helping the house "Breathe". By the way, this property allows the heat-insulating materials under the siding finish, such as mineral wool or polystyrene slabs, mounting the so-called ventilated facade. In addition to siding, the cottage trim is used.

The only drawback of the siding facade is that many consider it not too attractive from aesthetic point of view. According to many designers, at home with such a facade looks "cheap", similar to production facilities. However, this is a subjective point of view.

Facing brick. Decorative material, which has been used for quite a long time for facade works. In addition to its beautiful appearance, which is achieved by the almost perfect form and a wide palette of colors, allowing to create an amazing appearance of the building, facing brick is an excellent insulation. Thanks to polymer additives in clay, this material has high strength, reliability and durability. Facing brick practically does not absorb moisture, perfectly withstands the temperature differences and the direct ingress of sunlight. The only drawback of this material is the complexity of editing. Works on the trim of the facade of giving facing bricks must be entrusted to a professional bricklayer, because a bad laying will destroy all the beauty of this material.

Fake diamond. Truly magic material capable of putting the construction excellent appearance, special charm and effect. This finish perfectly harmonizes with other finishing materials, especially with a tree.

In comparison with natural, artificial stone has not too high weight and does not require the presence of a powerful foundation. In addition, there are already ready-made elements for various parts of the house (slopes, foundation), which reduces the work time by fitting the material.

Of the shortcomings of this method of finishing the facade, it is worth limiting the complexity of the work of work, the need to purchase special adhesive compositions, surface preparation. Such work is almost impossible to fulfill without certain skills, experience and knowledge.

Tile or Ceramographic Tile. These are modern facing materials that are characterized by their beauty and excellent technological qualities. Of these, first of all, it is worth noting a variety of colors and sizes of material, which is a strong side when developing various facade design options. In addition, the porcelain is not hygroscopic, and is rather durable. As for the shortcomings, this material for finishing is quite expensive, and it is necessary to work with it only to professionals.

Wall decoration on the cottage plaster

So, we have initially such conditions:

- A small house made from slag blocks laid in one row.

- It is assumed to rest at the cottage in the Winter Weekend End, so the electrical heating system is installed in the house.

- As an inexpensive facade, a heater was chosen in the form of polystyurol slabs and plaster plaster.

For the production of work we will need:

- Polystyrene foam is better extruded with a thickness of 50 mm. The amount of material is calculated by the surface of the insulation surface plus 10% on the technological loss.

- Grinding of deep penetration on stone.

- Anchors "fungus" with a diameter of at least 6 mm and a length of at least 120 mm.

- Plaster mesh made of fiberglass.

- Primer under the stucco.

- Plaster.

- Facade paint.

From the tool, we take: spatula, trowel, perforator, mixer, level.

We begin work with cleaning walls. If someone tells you what it is not necessary to do this, then we are clearly talking to a shabashnik amateur that is unlikely to understand what we are talking about. From the surface you need to remove dust and dirt, as well as the protruding surfaces of the slag blocks and the solution. After that, we begin primer. To do this, use a wide painting brush.

After drying the primer, we begin laying foam. It must be remembered that the foam "does not like" long stay under the right sunlight, so work must be performed in the volume to finish in three days:

- 1 day - laying of foam plastic;

- 2 day - fasteners fasteners and styling of primer with a painting mesh (the primer should not hold for a long time, after drying it can crack);

- 3 day - grouting primers and laying plaster.

Painting can be carried out after the end of the plaster.

Phased procedure for performing work:

- For laying foam, it is necessary to dilute special glue. The consistency of such a solution should be slightly curved than sour cream. The glue is applied to the surface of the plates and the wall itself. Paste the foam is required below. Each next row is placed with overlapping. This means that the middle of the top row plates must coincide with the joint of the two plates of the previous row. The first panels of some rows will need to be cut in half. It is very easy to do with an ordinary knife.

- After the foam plastic is laid, we begin to roll it with a dowel. One of them is driven into the middle of each plate, others in the butt plates so that the dowel hat keeps several panels. Dowel is better to choose from plastic, they are less susceptible to corrosion. First, the hole is drilled, then the sleeve sleeve is driven, and a nail is clogged with the last step. To do this, use a rubber hammer.

- After fixing the foam assembly mesh. To do this, we breed the primer and apply it to the surface of the foam, glue the mesh and distribute another layer of primer. When the works are over, we give the mixture to dry.

- After that, we drag the layer using a grout mesh, the mixture of deep penetration and after drying it, we start plastering. This process is rather complicated and stretched in time, but a hurry here is nothing.

- When plaster is applied, let's give her a day, then become ground and after drying the primer, paints the front cater. It is better to do this with a roller, so the paint consumption will be small, and you can avoid the appearance of divorces and ilk. It is better to paint in two layers, then the color of the paint will be saturated and bright.

Dacha finish with their own siding

For the production of work on the garden, Siding must be purchased:

- Sidding panels and mounting elements.

- The framework elements (as a rule, they buy the same as for interior trim plasterboard).

- Insulation (mineral wool).

For starters, a frame of metal profiles is mounted. Depending on the thickness of the insulation, he must fall back from the house on such a distance so that there is an air gap between it and siding. Thus, we mount the ventilated facade. After that, layer of vaporizolation layer. As a rule, the membrane material is taken for this. It will allow the insulation to avoid moisture, which will be condensed on the warm wall surface. Next, krepim insulation. To do this, use the "fungi" dowels described above. After that, the layer of waterproofing is stacked, which is designed to protect the insulation from moisture from the outside. And the last step is recruited siding panels. Their installation is fundamentally different from the installation of plastic. In order to understand all the secrets of the work, see the photo of the dacha finish.