Fireplaces are becoming increasingly popular not only in spacious country residences, but also in small country houses, where there is not so much free space. By the way, specially for such cases are building angular fireplaces from bricks - they occupy quite a bit of space, well heated the room and serve as a spectacular decoration of the interior. Today we will talk about how to make one of these fireplaces with your own hands.

Content

Features of construction

Many consider angular fireplaces much more attractive than any other, if only because they have an unusual appearance and are able to harmoniously fit into the design of any room. You can start a fireplace immediately after the construction of the house or even a few years later. But it is better to still do this until it laying the finishing floor and interior decoration - due to the impressive weight of the brick design for it, it is necessary to make an individual foundation. If the floor is already laid, it will be necessary to disassemble it.

The design of angular fireplaces can be symmetrical or asymmetric. It is important to choose the right size of the future building in accordance with the established rules and features of the room.

The proportions of angular fireplaces:

- The width and height of the coaching compartment should be reduced 3: 2.

- The depth and height of the vent must comply with 1: 2.

- The size of the pipe depends on the size of the furnace and can be 1: 8-1: 15.

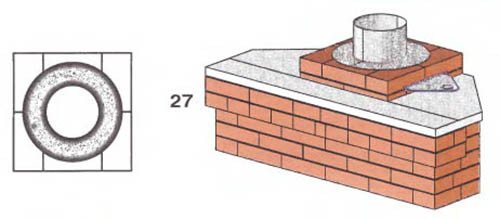

- The housing tube should always have a round cross section and be in diameter from 10 to 15 cm.

Fireplace trumpet

Without a pipe, no fireplace is unthinkable - it is necessary to leave the room to somehow flock gases and smoke. The size of the pipe and its diameter is determined by the dimensions and the power of the fireplace, as well as the layout of the building. Calculations are quite simple, and for clarity, we give a couple of examples: a fireplace with a portal 69x65 cm and a pipe 26x13, a fireplace with a portal of 76x49 cm and the same pipe.

At first we find the area of \u200b\u200bthe portals: in the first case it is 4485 cm², in the second - 3724 cm². The pipe cross section for both cases is 338 cm². Now it remains to identify the ratio of the portal area to the pipe area:

- for the first fireplace, it is 338/4485 * 100 \u003d 7.5%;

- for the second fireplace, it is 338/3724 * 100 \u003d 9%.

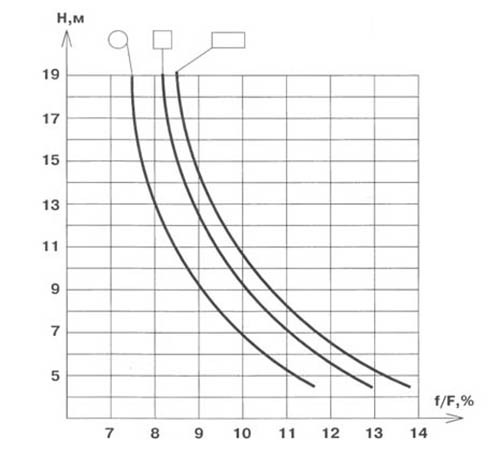

To check the results obtained, use the diagram below:

As a result, it turns out that the first fireplace will not be able to work at all if you do not reduce the portal or not to replace the pipe. In the second case, efficiency is possible due to high height, but it is best to use a thicker pipe with a larger cross section. Small deviations are permissible, but if they are very different from the optimal parameters of the diagram, the fireplace or it will not work at all, and the whole smoke will fit into the room, or will function with varying success. So, if due to bad weather, the thrust will weaken, the room will smoke, if you do not clean the chimney from the soot in time, the work will be impaired, etc. It is important to correctly calculate the parameters of the fireplace pipe, and also competently mounted it. Pipes in furnaces and fireplaces are subjected to serious operational loads, permanent temperature differences, chemical impacts, etc.

Social part

The base part of the fireplace is called a constructive element located under the fuel compartment. Its width is usually equal to 2.5-3 bricks. The base should be solid and reliably protect the external space and the nearby flooring from the ignition. When laying the base, it is necessary not to produce from the hands of the construction level - the appearance and quality of masonry of the entire fireplace depends on the horizontality of this element.

Most often, at the base right under the grade, a pull-out drawer for collecting ash is mounted. This is a kind of pallet, which from time to time should be emptied by fuel combustion products. But you can do without this detail, then the base will be a solid range of bricks. It turns out that it can be done or out of 1, or from 3 rows of bricks. If the fireplace is equipped with a pallet for ash, an additional row is usually placed above it.

Fuel compartment

The fuel part is considered to be the most important and difficult in execution. This is a special place in which fuel combustion occurs at extremely high temperatures, and therefore it is necessary to build it from a special brick. Typically, the masonry lead chamoten brick without dressing with the case. Dry joints form the so-called warm seam with a thickness of 2-3 mm, which does not allow the outer walls of the fireplace too much, so you can not be afraid of them. If you do a dressing, then too much expansion of chamotte bricks as a result of heating will lead to the fact that the usual red brick from which the outer sheat is made, simply cracks.

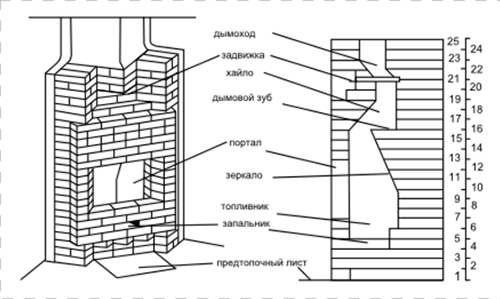

The dimensions of the fuel can be of great importance. The minimum depth can be 25 cm. The depth is the distance from the far wall to the inner edge of the overlap. On the rear wall of the compartment, there must be a "fireplace tooth", which we will tell a little later. The sidewalls of the fuel should not be strictly vertical, but to go with a slight bias of 30 ° (the value inaccurate and can be varied depending on the design of the fireplace).

IMPORTANT: If a cut brick is used for laying a fifuel, it's never cut to fire, because it is its vulnerable place.

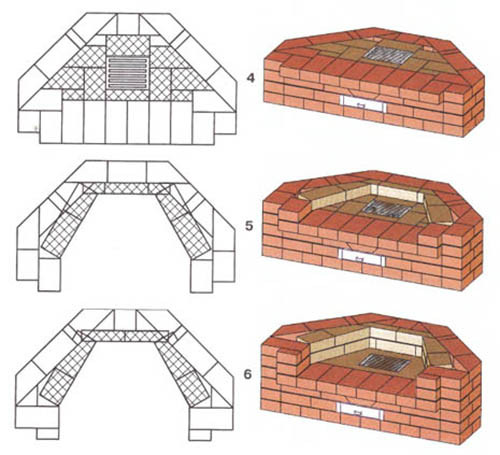

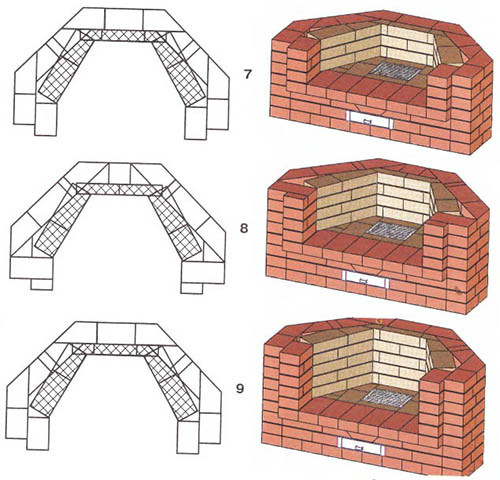

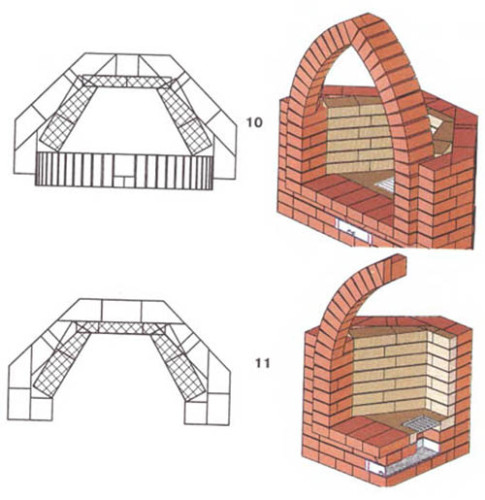

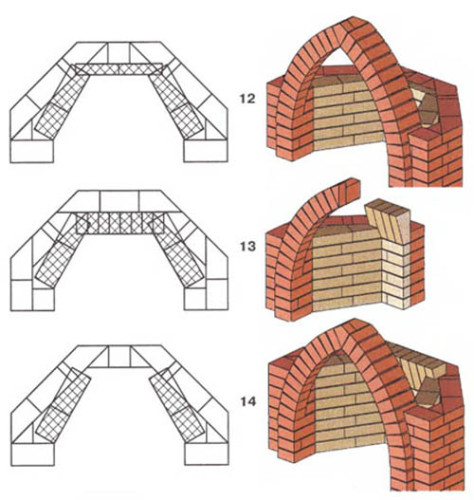

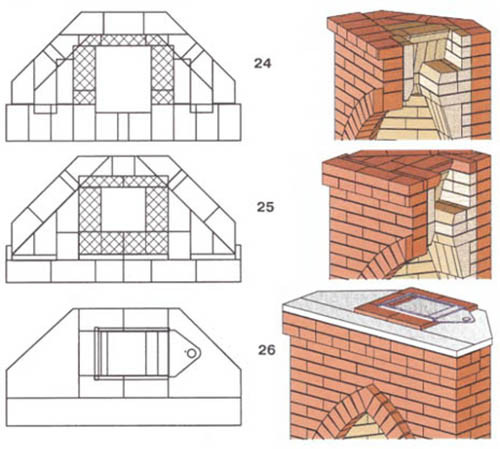

Overlapping for the fireplace

When choosing a portal overlap, the design of the future fireplace is taken into account. It is easiest to make a straight overlap with steel corners of the shelf outward, but in this case the facing of the fireplace is obligatory. In the image, it is shown below, though not an angular fireplace, but it can be seen on it, how to place the steel overlap and why it takes it then to be scenered. This is done, by the way, not only for beauty, but also because the metal is strongly rolled and can burn.

If you want to make an external decoration of bricks, both on the orders at the end of the article, you will need to build armed overlap. Whatever option you choose, any overlap must be done using a formwork - a wooden frame installed in the opening of the portal. This design is designed to form overlap and serve as a temporary support for brick laying.

Important: The overlapping should be located outside the working area of \u200b\u200bthe fuel compartment, otherwise it will interfere with the smoke to penetrate into the smoke collector. On the inside of the overlap, it is necessary to make chamders to give it a streamlined shape and speed up the movement of the smoke.

Fireplace

This item with a strange name is a small platform located on the back of the fuel chamber under a slope of 20 °. A loaded platform is located between the fireplace tooth and the overlap, for example, at 12, 15 and 18 cm in small, medium and large fireplaces, respectively, will pass the mixture of coolery gas with cold air moving at high speed. Lifting into the smoke collector, gases increase in volume, as a result of which the speed drops, and in a pipe where less space increases again.

Since over such a platform, the speed of air flow drops sharply, the discharge zone (injection effect) is created there. Due to this, an additional oxygen subchair in the portal is carried out, and the furnace gases quickly leave the room. Thus, the fireplace tooth provides stable and high-quality work.

On the video below, you can see the project of the corner fireplace from the "Annushka" brick:

Calculation of sizes

Before you go for the materials and start a masonry of a fireplace from a brick, you need to calculate its dimensions and decide on the form. First of all, the calculations of the flue separation should be made - the power of the fireplace will depend on it, and therefore the dimensions of the remaining components will depend.

In the rooms with the standard ceiling height, the ratio of the opening of the furnace chamber to the area of \u200b\u200bthe room will be about 1:50. If the room is 15 m², the portal area will be 0.3 m² if the room is 20 m², the portal will be 0.4 m², etc. It should be borne in mind that the height of the portal must be 1/3 less than its width.

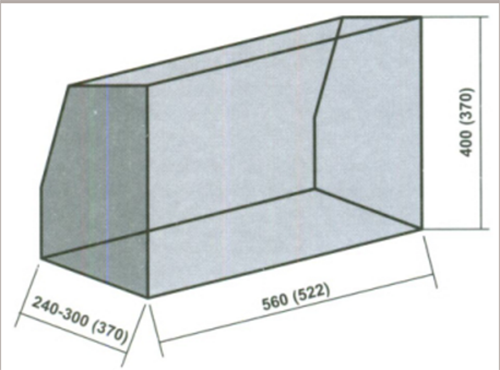

In the image below you can visually assess the correct proportions of the fireplace firebox:

Smoke from the furnace rises to Heilo (smoke collector), passes through the pass that does not allow smoke and sage to get into the room. Above the smoke compartment is a special catch for overlapping cold air access from the street through the chimney when the fireplace is not used.

Think well where the future corner fireplace from brick will stand. The size of the design should be harmoniously fit into the interior or even influence its formation. So, around the fireplace you can put the chairs and a coffee table, organize a workplace nearby or simply sash the warm carpet. When choosing a place, determine where the chimney through the floors to the street will be held. For this, the outer corner of the room or the inner is suitable - this is a matter of taste and depends on the planning.

IMPORTANT: If the walls of the house are made of wood, they must be closed with tin or asbestos sheets so that they do not light up from the highly heated walls of the fireplace.

Drawings fireplace

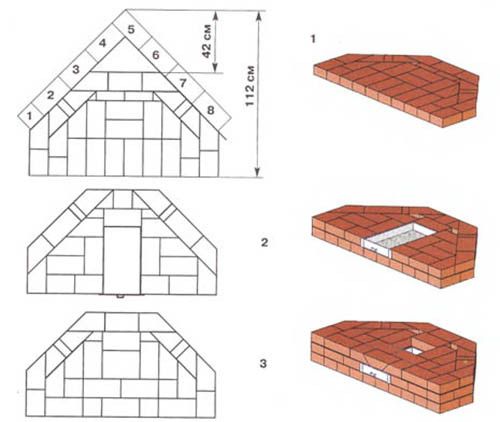

When the location and dimensions are finished, it remains to decide on the sequence of work. Fortunately, for this there is such a useful thing as a friend. The angular fireplace of the brick, like any other, build "on the eye" is impossible. Effective result is possible only in the event of strict compliance with the instructions.

The order is needed not only to see each step, but also for calculating the required number of building materials. It shows in detail how many bricks are needed at each stage of work, so it remains only to fold all the data and do not forget to add 10% about the reserve (in case of repair, marriage or battle). At the very end of the article, you will find a detailed order of one of the variants of angular fireplaces.

Materials for the fireplace

For masonry of fireplaces, you can use only clay full-length burned and chammatory brick. In addition, you will need a clay masonry solution. It is made from sainted fine sand (better career, not river) and clay (ideally blue). For strength to the solution, portland cement is added not lower than M300. For the construction of a durable foundation, a crushed stone is needed, chammed or brick crumb. The grace will be made from the reinforcement, and the portal jumpers are made of steel corners.

The fuel can only be uploaded to chamotted bricks, and the body and chimney - clay red. In the event that the fuel compartment is separated from the fireplace chassis "warm seam", a perforated brick can be used for laying the latter, saving on materials. For masonry of the part of the chimney, which is located outside (above the roof), you can take a finishing brick, since it has a high weather resistance.

Useful advice: It is better to use a brick from one batch, pre-making sure that: materials must be without cracks and chips.

When kneading the solution first, ask for sand through a sieve with 1.5 mm cells, and then add it with small portions to achieve perfect consistency - the solution should slightly adhere to the trowel. The proportions of clay and sand depend on the fatty clay. Approximately take them in the ratio of 2-2.5 parts of clay and 1.5-2 parts of the sand.

Step-by-step instruction

In fact, the masonry of the angular fireplace from the brick does not differ from the usual construction, with the exception of thin seams - the thinner they will, the better the fireplace will keep warm inside. For this, the solution should be as homogeneous as possible and without lumps. Permissible chimney thickness - from 1 to 3 mm for fuel compartment and up to 5 mm - for chimney and housing. At the same time, the seams must be filled completely.

How to build a fireplace from a brick:

- It's easier and faster to build a fireplace in the process of building a house when the interior finish has not yet begun. First of all, it is necessary to take care of a sustainable foundation, the dimensions of which should be wider than the base row of 5 cm on all sides. Having cut the appropriate size of a depth of 60 cm. If the floor level is located much higher than the surface of the Earth, you only need to carefully compact the soil under the future fireplace and make a formwork from wood. From the inside of the formwork shields, deem with bitumen mastic or attach the rolled waterproofing (the usual rubberoid is quite use). Sheet iron can also be used for making formwork.

- Find the bottom of the pit and pour a layer of rubbank or brick crumbs with a thickness of 10 cm, pour water and thoroughly wrap. The surface should be as smooth and horizontal as possible.

- At the rubble "pillow", install the formwork, then put inward large stones or brick battle (Booth). Between the stones will remain the gaps, and to fill them, pour some more rubbish.

- Six the classic cement-sandy solution in a 1: 3 ratio. First, mix the dry components, and then gradually add water, bringing the solution to the desired consistency (thick sour cream). Pour the concrete in the formwork with a layer of 10 cm, align the surface and leave to dry for a day.

- The next day, again put on a dried concrete layer of boot in front of the rubble and fill with concrete. Thus, bring the foundation almost to the level of the first floor (below 5 cm). Align the last layer of concrete thoroughly, cover with polyethylene so that it does not crack, and leave to dry for 5-7 days.

- After completely drying the foundation, dismantle the formwork.

- Close the foundation 2 layers of rubberoid and proceed to brickwork in accordance with the selected friend.

- Since bricks absorb moisture, before laying and applying the solution, they should be held in water 2-3 minutes. If this is not done, they will pick up all the liquid from the clay solution, and it will lose its strength bonding characteristics.

- When laying the base row, install bricks on the ribs. For the remaining rows, bricks are plashed. When the height of the structure reaches 25-30 cm, you can start forming the walls of the flue compartment.

- If the facade of the fireplace is not planned to plaster or facing, when laying the front part, try not to bring the clay solution to the very edge of the brick about 5 mm - this will allow you to make a beautiful seams. Getting started to layout each row, check the horizontal building level, and the verticality is a square and a plumb.

- When you lay out the fuel and smoke cameras, smooth and align the solution with not tools, but manually. So you can feel and, if necessary, timely remove large particles and lumps by taking the seams thinner. When we cope with 5-6 rows, wipe the inner walls with a wet rag, to erase the excess solution - then it will be quite difficult to do it.

- If you tie the masonry of the fuel, the facing must be performed separately without dressing so that the temperature differences did not destroy the design.

- If you remember, the rear wall of the fuel compartment and the smoke collector must be under the tilt. To do this, lay each subsequent row with a slight bottom to the lower (4-5 cm). In order for such a "ladder" soot, the laying is recommended to close the steel screen with a thickness of 3-4 mm.

- To make the portal overlap, use the steel corner (the fireplace cladding is required) or grinding - a special formwork that allows you to create arched masonry. To make everything beautiful and correctly, first install a brick without a solution, evaluate the result, and then lay it on all the rules.

- When you bring the chimney to the roof, change the clay solution to cement-sand - it is better coping with atmospheric load.

The diagram of the corner fireplace from the brick, whatever simple it, requires marginal attention and work skills. If you doubt your abilities, it is better to entrust work a professional or at least enlist his support and recommendations.

Corner Fireplaces of Brick: Photo

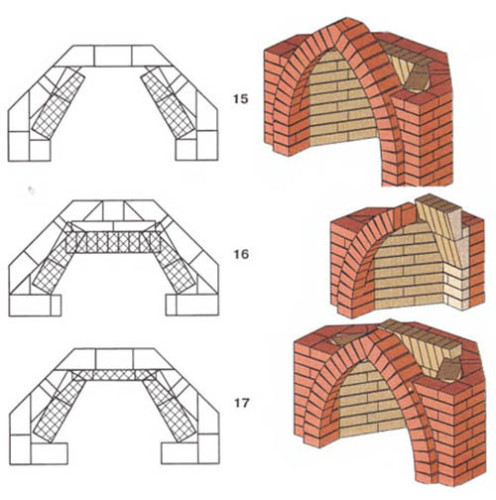

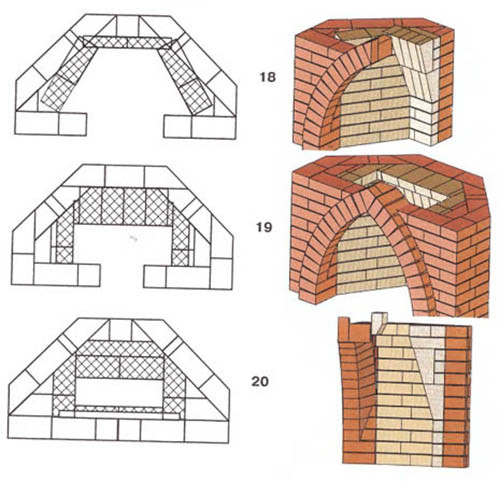

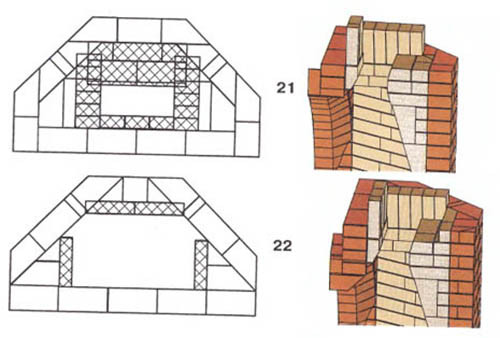

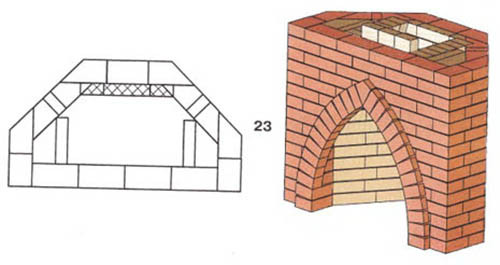

As we promised, we suggest you look at the detailed order-drawing of the corner fireplace from the brick. Perhaps this is exactly the way you want to build at home.

And we first wanted a fireplace full for the cottage, but the construction campaign decided to abandon this idea in favor of the Iron with the door, this is something like this https://www.prostoteplo.ru/kaminy/kaminnye-topki/kaminnaya-topka-kratki-jas/ Only execution in modern, in principle, not bad and a lot of pros, but about the classic in the style of the Victorian era and Sherlock Holmes still miss. They just wanted to simplify life, we use often, and from the brick, all the same more brand seemed, and the article is very good of course, well, maybe next time 🙂 brick will do. I wish you all the incarnation of a dream and desires!