The question of how to make fallen on the roof sooner or later becomes before each owner of the private house and it is not surprising. These elements prevent the roof of the roof of atmospheric precipitation to the surface of the roof of the roof, which in turn does not allow moisture to penetrate inside the building and thereby warns its destruction. Water goes down, after which it is assigned to the drainage system. They are divided into several types depending on the material on the basis of which are made. Consider all the features of the choice and installation of structures in this article.

Content

Varieties of sings

The modern construction industry offers various types of structures that are based on manufacturing material, operational parameters and cost. Consider more detailed every species:

- Steel lines are products that are produced from galvanized steel sheets with a thickness of 1 mm. In defective purposes, the design data is further coated with a layer of plastic material - plastisol or polyester. This coating helps to avoid corrosion processes.

- Copper is made on the basis of untreated copper raw materials and are coated with an oxidized or brass material. These elements are beneficial from other varieties with good aesthetic indicators and durability. But at the same time, their cost is quite high, which prevents widespread use among consumers.

- Aluminum foals. Their thickness ranges from 0.8 to 1 mm. The presented products in the production process are processed by a special varnish, which prevents corrosion.

- Plastic foals for the roof. The basis for the manufacture of these structures is the polymer material - plastisol and polyester. Thanks to the wide list of advantages that are distinguished by products, they are in great demand. The main advantage is their affordable price comparatively with aluminum, steel or copper products. In addition, plastic-based products have low weight, high strength, do not destroy under the influence of ultraviolet and retain their operational qualities for a long time.

All products, regardless of the basics used for their production, have the same shape. They resemble a chute with a slight depth, having a bracket, through which products are fixed. The length varies within 1-6 m and depends on the roof parameters. Thanks to the large selection of color gamut, you can pick up the color of the roof and drain.

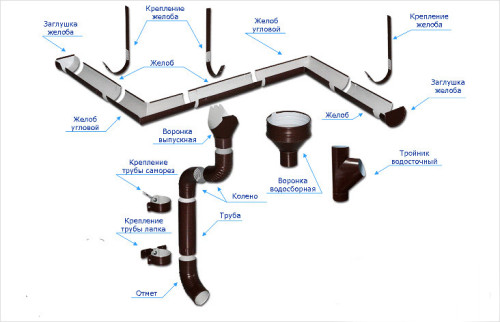

The design of the drainage system consists of the following details:

- The main element is a drainage chute. It comes from the skates water, which is then discharged into the pipes.

- Also, the system includes funnels, which are transient fragments between the pipe and the chute. According to the current standards, these elements must be installed along the entire length of the skate. In private households, the placement of funnels on all parties is practiced.

- Down water is discharged by drainage.

- Next enters the wells intended for this purpose, then in trench deepening and beyond the territory of the territory.

- In addition to the main parts, the design is the connecting inserts, brackets for fixation, decorative plugs for the ends.

The installation of the roof of the roof will allow solving a number of tasks. This will protect the structure from moisture penetration. In addition, the fits close the seams, so that the appearance of the building becomes more presentable. All roofing design acquires even greater rigidity.

Rules of calculation

Before starting the installation work, you should define the required sizes. If you install this item inappropriate width and depth, it will not cope with the functions assigned to it. The desired parameters are determined taking into account the effective area of \u200b\u200bthe roof, which is calculated as follows: the area of \u200b\u200bthe roof \u003d length * (height of the roof / 2 + length of the skate).

It is also necessary to take into account the distance between the places of turns of the drainage and gutters, which must be located above the drainage.

At the settlement stage, such factors should be taken into account:

- For each slope you need to install two gutters.

- Installation should be carried out with a slope towards the water pipe.

- It is also important to correctly select the diameter of the gutters. It is important to take into account the load on the drainage system. What they are more significant, the larger diameter there should be a gutter.

How to make the roofs on the roof do it yourself from the metal pipe

Installation of ties is not the most difficult task and it is quite possible to cope with it yourself. Works can be performed in several ways. Let's start considering from the simplest option:

- For work, a metal pipe with a diameter of 160 mm and more, which should be cut in the longitudinal direction. The result will turn out two chute.

- Before mounting, they need to be treated with special anti-corrosion products, after which it is painted using a material containing plastic inclusions.

- After the necessary processing are fed at the appropriate places.

How to set fucked on a roof with a metal sheet

Single can be made of metal sheet material. In this case, the product in the form will resemble a rectangle. For manufacture, it is necessary to prepare such materials:

- metal sheets with a thickness of 0.7 mm and more;

- a sheet bending machine that can be purchased in the specialized points of sale of building goods;

- disk saw or bulgarian.

Works on the construction of low tissue look like this:

- From the sheet you need to cut stripped fragments with a length of 3 m. The width must correspond to the perimeter of the low tide. It should be added to it so that the metal can be fed to the machine.

- The finished metal bands are placed in the machine in which the desired gutter contour is installed using rolls.

- Next, the strip is rolled and thus obtained the sampling.

- Then the product must be covered with a special composition, which will protect the chip from corrosion.

- The next step is the painting of the structure.

- In the next step, it is necessary to install brackets by which the installation of sings for the roof will be carried out.

- When installing these fasteners on each meter of gutter length, the slope is 3 mm. Thanks to this, the water coming into the tump will be completely excreted from it, which will help to avoid wagia and foreheading.

- So that in the process of fastening the low tide does not damage the protective coating when mounting the rubber gasket with a thickness of 1-2 mm should be used.

- At the final stage, drainage gutters should be checked. For this, water is started.

Films from alternative materials

There are cases where ordinary plastic bottles are used for the manufacture of a drainage system. At the same time, the process of facing the popularity looks like this:

- To get the gutter they are cut into two halves.

- For the formation of vertical pipes from bottles, a small part is cut in the neckline.

- Details obtained in a similar way are inserted into each other. At the same time, they should be tightly fixed.

Based on the reviews, it can be concluded that such structures work quite well and fully cope with their task.

The only disadvantage is the appearance, these drains look not very attractive. Owners of houses that are not confused by the aesthetic aspect of such a system can experiment with plastic bottles. Especially since the installation process does not take much time, and the material for work is cheap and affordable. In rare cases, lowers are made on the basis of natural stone or ceramics. But such products do not use wide popularity due to the high cost of products.

Features of mounting work

When installing sings, it is worth considering a series of rules that will help make an efficient and durable design. The main aspects include such:

- Before installing the sings, it is necessary to make receiving wells. In the absence of such a feature, funnels should be positioned so that the diversion of moisture does not fall on the paving slabs and plantings.

- The brackets can be mounted both to the wall and the edge of the roof. In the latter case, installation work should be performed before laying roofing material.

- Plastic foals are installed for the roof in accordance with certain rules:

- the fasteners under the gutters are installed after 60 cm from each other;

- two brackets should be located on both sides of each funnel at a distance of 2 cm;

- works should be started with the installation of extreme brackets that are attached through self-tapping. It should not be forgotten about the slope of the gutter;

- next, the cord is stretched between them, which will perform a reference function when installing intermediate hooks;

- to fix one bracket requires two self-pressing.

- Fragments of the gutter can be recorded both online and brass. You can close the joints using special linking linings.

- When working with plastic gutters between fragments, a small space is left. On the bottom of the lining from the inside, the adhesive composition should be applied, after which it is fixed in the area of \u200b\u200bthe jaw joint.

- At the next installation stage, end plugs are installed. In plastic drainage, this is done using glue, which is applied to the edges. When installing galvanized parts, you need to bend the edge, put the plug and adjust the edge back.

Fastening of the funnels also has its own characteristics depending on the material from which the sampling is made. When installing a galvanized product in certain places of the chute, holes are made. Then the funnels need to just snap, performing the movement from the bottom up. In the process of installing plastic drainage, these elements are installed first. Further, fragments of gutters are inserted on both sides and from above. The adhesive composition does not apply.

Next, the drainage pipe is installed. This process involves several stages.

- Initially, the first drain knee is mounted at the bottom of the funnel.

- Then, with the help of the metal hacking, it is necessary to cut off the pipe fragment, which will perform the function of the connecting part between the first and second knee.

- To properly determine the length of this fragment, you should navigate the vertical pipe, which should be separated from the wall 2-3 cm.

- Then the installation of the vertical segment is performed on the lower knee, after which all the remaining pipe elements are mounted.

- Fastening parts must be installed on the walls. At the same time, each fragment of the pipe should be placed on two fixing clamps.

- At the end at the bottom you need to attach a discrepancing element.

Operating rules

In addition to studying the issue, how to attach the roof to the roof should consider the features of the operation of structures. The main of them should include such aspects:

- The drainage system does not require careful care, but necessary to adhere to certain requirements during its operation. For at least two times throughout the year, the chute must be cleaned, as the dirt, il and fallen leaves accumulate in it.

- This rule is especially true for plots on which many trees are growing. In the reverse case, the system will be scored.

- On the chute you can install special filters that will pass water, preventing garbage treatment. They are attached along the entire length of the skate.

Conclusion

Fallets for the roof perform a protective function. They remove from the surface of the roof incoming as a result of precipitation moisture, which makes it possible to avoid the destruction of the house. Today, lowers are made from various materials: plastic, copper, aluminum, steel. Also products are processed by special means, due to which they do not lose their operational qualities for a long time. The procedure for installing a drainage system largely depends on the material on the basis of which these items were made. Installation is carried out in several stages. At the same time, the technology of work does not represent a special complexity. Therefore, the installation of sings can be performed on its own.

How to make foals on the roof. Video: