Before the homeowner of the country site, the question of installing the fence is easily or late. This design is a structure, the main task of which is the designation of the boundaries of a certain area. The fence can be open or deaf. Today, for the manufacture of fences, various materials, such as wood, metal, concrete, brick are used. However, one of the most sought-after materials are special blocks that, in addition to the practical task, perform aesthetic function.

Content

Block features

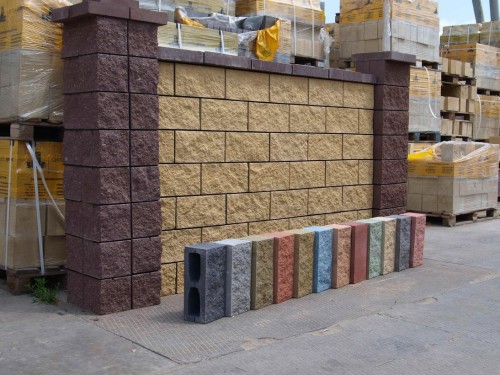

Decorative concrete blocks for fence are products consisting of two M-shaped elements. These designs have a decorated surface on both sides, which makes it possible to get an original fence both from the street and from the courtyard. Today there is a wide selection of surface decor options. It can be imitation of a split stone or smooth plaster.

Blocks, the surface of which is exactly repeated by the root stone, enjoy the greatest popularity. Natural stone refers to expensive materials. And the use of these blocks allows you to get a fence, visually resembling a stone fencing, and at the same time save significantly.

Another advantage of using such structures instead of natural material is to simplify installation. One of the characteristics of products can also be considered the correct geometric shape, which simplifies the laying and contributes to the economy of the cement composition.

Block varieties

In addition to standard blocks, the construction industry offers various types of their varieties. For example, splitter products. These structures are hollow bricks of large size, which consist of two halves. In its parameters, the splitter type block seven times higher than the standard brick. This is positively reflected at the velocity of masonry.

Along with concrete material for the manufacture of decorative blocks, wood is also used. Wooden blocks are a type of the Haus block, however, their outer surface is convex, and internal - smooth. On the inside there is a slit groove, thanks to which the load on the material is reduced. The assembly is carried out using side grooves. The fence erected from such products is an improved version of the traditional wooden fence. In its appearance, he resembles a log house.

The design of such a fence is mounted blocks and support pillars. The fence from the House block is installed in two stages. First of all, supports are installed. During the second stage, which is performed the next day after soloing the solution, mounted blocks are mounted.

Fence from blocks. Photo:

Auxiliary details

In addition to decorative blocks, additional components will be required to build the fence. These include such products:

- Fiberglass caps. These elements may have a backlight that gives the design a more spectacular view.

- To create aesthetic effect, metal plugs of a spherical or straight form are used.

- Also, additional details include concrete vertices, which are especially in demand when erecting combined fences.

- As additional elements, carved and forged lattices are applied.

Decorative blocks for fence possess the following advantages:

- long service life;

- strength;

- resistance to temperature drops;

- high decorative qualities;

- available cost.

The fence erected from blocks is characterized by high strength, while the installation is carried out within a relatively short time. For mounting one block, it will take as much time as necessary for laying seven facing bricks. A wide variety of design options allows you to choose a material for every taste. And thanks to high aesthetic indicators, the established fence has an attractive and spectacular appearance.

Internal blocks of blocks can be used to premise communications. In the event of a fire, the fence does not threaten any danger, since fragments are made of non-phase material.

Supports and pillars

There are several options for installing blocks. One of them is a brickwork, which is placed on the foundation base. This is quite a strong support, but it is worth considering that, if necessary, move it to another place it will be impossible. If you need to dismantle the design, the process will require considerable effort. A simpler version is the use of column blocks.

Decorative blocks for fence columns have a cavity into which pipes, fittings are laid and a concrete composition is poured. Installation of these structural elements is carried out by installing them on each other. To fill the space between the colums, forged elements, wooden stakenants, decorative plates or concrete blocks are used. Poles have grooves, with which panels are installed. Pages can be located on both sides.

Preparatory work

The installation process can be divided into three stages.

- In the first stage, the material is transported and its unloading.

- During the second stage, the marking of the territory is performed.

- The third implies the installation of columns and blocks. To facilitate installation work in the process of unloading, the blocks should be placed along the future fence.

Before building a fence from blocks, the first thing will be necessary to post the area on which the installation is assumed. This procedure is performed as follows:

- On the axis of the fence, pegs are clogged on which the cord is stretched. It is necessary to determine the central points of the future bases of the fence and in these places score pegs.

- Poles must be located at a distance of 205 cm from each other.

- For the maximum accurate detection of the distance between the columns, you can make a template.

Further work occurs in such a sequence of actions:

- Focusing on the marking marking, in the soil you need to drill holes. First of all, the holes are made at the corners or at the location of the future wicket and the gate.

- In the corners you should install two columns. When working with soils containing non-dried lugles, the sizes of the hole should be 120 cm deep and 30 cm in diameter.

- If you are dealing with a flooded or clay soil, you need to create a sliding layer using a rubryoid and asbetic pipe, which will prevent bunch processes.

- During the work, the markup should be accurately followed as accurately as possible, permissible deviations should not be more than 10 mm.

- With the level of the left level, the top points must be set according to the level according to the markup.

- During the third final stage, the installation of columns and blocks is performed. Pillars installation work should be started with an angle or from the point of arrangement of the gate and gate.

- After installing the first post, the following must be mounted, focusing on the template. It is also necessary using a plumb or level to track the verticality of the position of the column.

- If during the installation, the fence should be rotated, then two columns are installed in the appropriate place.

- If the area on which the installation is produced is not even, you should use columns of different lengths.

How to make a fence from blocks

First you need to prepare the basis for the future fence. This may be the foundation in the places of the column or the foundation of the tape type throughout the perimeter of the fence. Consider the technology of execution of each type.

- To get a columnar, you must first note the location of the column, after which the holes are digging. The depth of the wells should be 1.5 m, the diameter is to exceed the size of the pillar by 10 cm.

- Next to the bottom, the pillow of sand is pillow with a thickness of up to 30 cm, which should be moistened and tamper.

- Then the metal pipes are driven into the center of the base, the height of which should correspond to the height of the columns. Pipe diameter - 57 mm. And for those pillars that are installed in the placement places of the wicket and the gate, a pipe with a diameter of 89 mm is used.

- After that, the well is poured with concrete composition in several layers.

- The size of the belt foundation should be determined based on the parameters of the fence. The approximate depth of the base is 50 cm. At the same time, the pole should be on the meter deeper. In width, the recess should be 10 mm exceeding the block parameters.

- Concreting is performed in the same sequence as in the device of the columnar base. In a trench to install the formwork.

- Concrete mortar is poured first into the recesses for the pillars, and then to the trench itself. The base of the foundation after curing is recommended to treat hydroresistant means.

- Mounting blocks implemented rows. The work begins with putting a number of pole blocks around the perimeter, and then installed wall blocks.

- For fixing the posts used cement slurry, which is prepared according to the following proportions: 1 part cement and four parts sand. The composition should have a creamy consistency.

- Fixation of the series is carried by means of vertical reinforcing bars 12 mm in diameter, which must be pre Drill into the ground.

- Blocks are placed for collection as follows. Each successive adjustment unit relative to the bottom is displaced by 200 mm.

- In the process for fixing the masonry blocks to be used with tile adhesive hydroresistant and frost resistant properties.

- Then it is necessary to wait until the glue hardens and fill the interior cavity with concrete mix blocks. Pre surface blocks need to moisten water.

- At a time shall be completed no more than 3 units since otherwise structure may collapse under hydrostatic pressure.

- Embedded parts with which will be assembling spans are attached to the pipe by welding.

If the height exceeds 4 fence block structure should be strengthened by means of reinforcement. If the fence does not exceed this height, in the use of reinforcing elements is no need.

If the use of reinforcing rods is necessary, the wall should lay the data elements in both the longitudinal and transverse direction. At this fence masonry blocks is completed. In conclusion, it is recommended to paint the design cover and waterproofing composition.

Possible errors in the process of work

Committed in the course of installation errors can cause unpleasant consequences during the sampling operation. Improperly installed poles will lead to the destruction of the carcass. Consider the most common omissions masters when installing fences:

- The main mistake when installing the poles is their lack of penetration. As a result of this support will be freely tilted in different directions.

- Incorrect lines of columns relative to each other can provoke panel loss. The distance between the columns must correspond to the length of the section. Deviations even by 2 cm may have negative consequences. Their probability can be minimized if you use high-quality panels that have good resistance to vibrations.

- In order to completely exclude the possibility of panel dropping, it is recommended to extract all available gaps after the installation work.

Conclusion

Today, the construction market offers a large selection of materials for the construction of fences. One of the most sought-after among them are decorative blocks that perform several functions at once and have a significant amount of advantages. Along with durability, resistant to the effect of high and low temperatures, the durability can distinguish special aesthetic properties. Decorative blocks have a surface imitating various materials. So, with the help of blocks, you can get a fence that in appearance will resemble brickwork, split stone or wooden fence. At the same time, the cost of such a fence will be significantly lower than the structures erected from natural materials.

Fence from blocks. Video: