The design of water supply and sewerage pipelines is a very important stage of construction of your own home. A competently composed line of layout of lines and a clear following the rules when making installation will certainly provide long-term operation. In addition to these requirements, regardless of the quality of the quality and type of basic building material for engineering systems, consider the need to warm the outer and underground branch. To more clearly imagine possible options and scope, look at the recommendations set out below.

Content

Why do you need insulation of pipes?

Such a procedure will be not just a fairly profitable solution. The correctly chosen technology will affect the entire subsequent operation of the building. We give only some benefits of completing such work:

- longer period of use;

- preventing the freezing of the pipeline during the cold season;

- guaranteed uninterrupted operation of systems, regardless of the speed of temperature drops;

- no pipeline deformation;

- reducing the risk of system destruction due to the influence of natural phenomena.

What materials use?

Make a choice of material to protect the pipeline independently, based on the most suitable criteria for technical indicators, the volume of the required work, financial capabilities, features of the system line structure.

Consider the most popular solutions to date to fulfill this work:

Criteria for selecting material

To insulate the pipeline correctly, pay attention to the following requirements for insulating material:

- Low thermal conductivity.

- Easy installation.

- High indexing indicators.

- No properties of ignition and burning.

- Resistance to temperature drop.

- Good tightness indicators subject to editing rules.

- Easy installation.

- Available cost.

Features of insulation glass gamble

Until recently, this method was the most popular option for insulation of the water supply pipeline.

To date, the market presents a fairly wide line of this material. When choosing this material, pay attention to the following more popular stamps:

Low density and porous structure of mineral wool provide good air circulation, which eliminates the appearance of rust and rotting pipes.

Important! With the help of glass gambles, follow the insulation of only those pipelines that are outside. For underground lines, this material is not acceptable, since the density, and, accordingly, decreases all specifications, and, accordingly, decreases.

Warming technology

- In order to correctly perform the installation of glass gambles on the water pipeline, prepare not only the insulation itself, but also an additional protective material for cloth bonding.

- Wrap the entire surface of the mineral wool pipeline.

- Do not strive to compact the canvas.

- While winding from plastic or polymer adhesive tape.

- Create an additional waterproofing with a roll rod rubles.

Heat insulation paint

One of the new directions in this area of \u200b\u200bconstruction. The use of the heat-insulating solution is becoming increasingly popular due to the simplicity of application, excellent indicators of resistance to any aggressive effect on pipelines, even made of metal, and a very long exploitation.

A very important point is the impossibility of destroying the decorated coverage even after 30-40 years due to dense adhesion with the surface of the pipes. The only nuance, which sometimes limits consumer capabilities is the need to use a special pulverizer and a higher price that fully corresponds to the quality of the created isolation and insulation.

Important! The basis of such paint is water and acrylic dispersion, mixed to consistency thick paste. There is an opportunity to choose a more suitable shade to achieve not only technical compliance with the specified parameters, but also make the pipeline outwardly attractive, is a classic white or more neutral gray.

Application method

- Clean the surface of the pipes thoroughly from contaminants to ensure good grip of the solution.

- Stir the solution.

- Take the mixture into the crash and prepare a roller, slightly swaying it.

- Spray the uniform layer or cover the entire surface of the paint manually.

- Wait for drying in accordance with the period specified by the manufacturer.

- Repeat the application procedure several times.

Important! The more layers and the thicker they, the more reliable and qualitative will be insulation. Therefore, if you prefer exactly this method, do not save on the consumption of paint.

Basalt, Penoplex, Polyurethan

We note some features of the technical characteristics of each type:

- Basalt fiber is characterized by special strength and stability not only to corrosion, but also stretching, which certainly accompanies the cycles of frosting-thawing. The basis of such a material is a stone rock, which distinguishes it from the other types of insulation. But it is not always available for the consumer in view of the expensiveness.

- Penoplex. The basis of this material for insulation of the pipeline is extruded polystyrene foam, which provides a fine-grained structure of the formed canvase. It is great for the outer, and for underground insulation, regardless of the quality of the soil. It is the penplex that holds the leading position in the market due to its indisputable advantages in the form of moisture resistance, fire safety and environmental purity in combination with a very affordable price.

- Polyurethan. This material has a sufficiently dense, but at the same time a porous structure. The presence of cells in the thickness of the canvas ensures high indicators of the heat-saving property. Perfectly opposes destruction under the influence of any natural and artificial phenomena.

Montaja technology

Given the features of the form of the release of all the above materials in the form of a cylinder or profiled shell, for all these insulation, the installation method will be the same. The whole process does not require any special skills, additional materials and tools, and excessive effort. Therefore, the most profitable decision will be the acquisition of one of the materials of this species category.

Despite the simplicity of technology, familiarize yourself with some rules to ensure long-term operation and prevent pipelines freezing:

- Carefully measure the length of the pipeline that needs to be inspired.

- Mix the diameters of pipelines in different parts of the line.

- Calculate the number of joints and turns.

- Take the configuration schemes to accurately select the appropriate insulation details.

- When buying, be sure to check the presence of all necessary parts.

- All installation work, follow directly before the pipeline laying line.

- Installing all the insulation elements, perform sequentially on both sides of the pipe.

- When installing, observe the shift of one half relative to the other by 10-15 cm to ensure maximum sealing.

- Crerate all elements of the decorated coating with insulating adhesive tape.

Why should it be warmed by a water pipe warmer cable and how to do it?

Despite the complexity of the entire process of insulation using a heating cable, give preference to this method in the following cases:

- The pipeline connection is made not to the centralized network, but to the local well in its own area.

- It requires the minimal blowout of the water supply due to the features of the soil.

Important! This method will allow independently adjusting the temperature inside the pipeline and the natural circulation of water.

Materials for insulation

Distribute in advance the length of the pipeline and in accordance with the obtained parameters, prepare the desired amount of the following materials:

- foil Scotch;

- plumbing adhesive tape;

- moisture-resistant rolled insulation;

- self-regulating heating cable with a capacity of 20 W / m;

- temperature sensors.

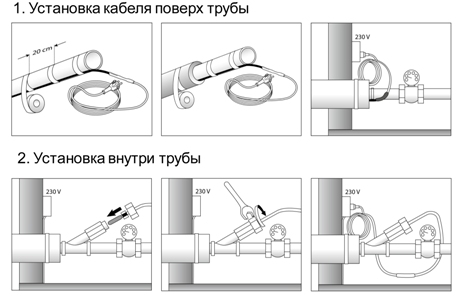

Important! There are two methods of installation - internal and outdoor. The first is characterized by a special complexity, so it is better to attract competent specialists for insulation this way. The second is completely undertaking to independently design insulation, but no less reliable and durable.

Montaja technology

Carefully read the sequence of work and do all the necessary steps in the exact following instructions:

- Carefully wrap the spirals of foil tape, withsting small intervals of free space.

- By the created line, put the warming cable.

- Reinforced the spiral from foil tape, but over the cable.

- Check the reliability of fixation.

- Cut the rolled insulating material with strips, the width of the width of the used tape used.

- Wrap over the created "pie" of their cable and foil tape.

- The locations of the nodes and exits of the pipe from under the ground will additionally refer to the polyethylene film.

- Fix with plumbing scotch.

- Secure several temperature sensors along the entire line of the water pipeline.

- Connect the installed heating system.

- Check the serviceability.

Video

Browse the videos in which two ways of insulation of the pipeline of the heating cable are clearly shown.

Option first.

The method of the second.

Conclusion

Regardless of the selected material and technology for designing the insulation of the pipeline on its own site, carefully refer to the recommendations for the implementation of all works. Only subject to all of the rules and the most appropriate material, the result will be long-term operation without various damage to engineering systems and their freezing during the period of jubus frost.