Currently, one of the most sought-after ways of external finishing of the house is cladding siding. This material can mimic various natural materials, including a tree, allowing the building a more aesthetic appearance. This finish is universal, durable and very functional, acting as an effective protection of the facade from the adverse effects of the external environment. In addition, the installation of panels is easy - the panels are attached directly to the facade of the construction or using a frame.

Content

Benefits of cladding siding under the tree

Traditionally, natural wood is widely popular as a building and finishing material. However, capriziness inherent in care and operation, inherent, such construction entails tangible expenses. You can avoid similar problems using a tree siding. This facing material appeared in the sixties of the last century in North America and Canada, and in a short time won wide popularity due to excellent thermal insulation properties, ease of installation and convenience in operation. At first, siding panels were solely wooden buildings, with the time of production technology of this material were improved. Currently, siding is used to finish buildings of various types.

It is worth noting that the facing of the house under the tree looks very natural, aesthetic and presentable, besides, in many characteristics, it is largely superior to the traditional wooden. The technology of manufacturing this facing material allows you to imitate the type of natural wood, as well as the bentness of the logs. This finish will help to give a special style of any construction. The universal palette of shades of siding for a tree house allows you to combine this trim with other finishing materials. For the facade cladding, you can use the material of one type or combine the panels in several color solutions, in any case the finish will look very original and effectively.

Among the advantages of finishing siding under the tree can also be mentioned as follows:

- excellent characteristics of heat and sound insulation;

- the possibility of facing without visible joints;

- resistance to adverse atmospheric effects and temperature drops (siding panels are able to withstand from -65 to 110 ° C);

- this finishing material is not subject to the appearance of rust and mold, as well as the effects of insects. In addition, such a cladding does not fade into the sun;

- siding under the tree is distinguished by considerable strength, so that when it is installed, it will not be necessary to further strengthen the walls;

- less high price compared to natural wood;

- low weight and convenience of mounting;

- this finish provides excellent ventilation of the building - with the correct installation in the premises, a comfortable microclimate and humidity level are maintained;

- fire safety - the blades of vinyl are not burning and do not participate in the spread of fire;

- efficiency of finishing and its environmental friendliness (in the manufacture of siding, materials are used safe for health).

Facing siding is distinguished by durability - the service life of the panels can reach 50 years. This finish does not need special care, including painting, it may take only a periodic washing of panels. If necessary, individual elements of the design of such a cladding are easy to replace. The disadvantages of siding under the log can be attributed to the fact that it is difficult to fix on curved or broken surfaces.

Types of siding under the tree

When the facades of country houses are increasingly used by siding cladding. To do this, use several types of siding under the tree - panels from durable plastic (vinyl and acrylic), as well as metal. Each of the varieties of this facing material is inherent in its advantages and disadvantages.

Metal siding under the tree

Modern manufacturers offer a wide selection of finishing material imitating wood texture facing. Metal siding under the tree is distinguished by the available price, as well as the versatility of use, as it is suitable for finishing buildings of various types. This finishing material is profiled panels of galvanized steel, on the surface of which a special polymer coating is applied, simulating the natural wood texture. From the back, such panels cover protective paint. In the context, the metal panel resembles a puff pie, in which the layers of the material ensure the particular strength of the building finish.

Metal siding has proven itself as high strength, reliable and durable facades. The panel of such a tree finish is distinguished by a low weight and do not create a significant load on the foundation of the building, in addition, this cladding allows you to adjust the irregularities of the walls. You can perform the installation of metal panels under all weather conditions, it will not take any special skills to perform such installation, as well as long-term preliminary preparation of walls. Houses erected from bricks or building blocks and decorated with metal siding under the tree maintain an excellent type of finishing for a long time without the need for repair work.

Plastic siding under the tree

Vinyl panels for facing facades of buildings produce from high-strength polymers and stained in various shades by spraying. Modern technologies allow embossing on the surface of plastic facade panels and is very believable to mimic the texture of the tree in its various kinds. The color gamut of vinyl siding under the tree is as close as possible to the shades of natural wood and is quite diverse. This cladding material is characterized by significant plasticity and mechanical strength, there are no cracks or breaks. The vinyl siding panels are distinguished by the forage resistance, as well as the effects of moisture and aggressive chemicals, they do not multiply the fungus or mold. In addition, due to the high levels of frost resistance, such a cladding is not cracking at low temperatures. Such a siding decoration is rather durable - its service life is 20-30 years.

Plastic siding under the tree is in a slight weight and does not take up much space, it is convenient to fold and transport it. This finishing material is equipped with reliable fasteners, it is easy to mount it. Such siding is not toxic, its application is allowed to clamp buildings in which children's gardens are located.

Vinyl siding on a log is characterized by a higher cost compared to the usual, but it looks more attractive and stylish. As the main distinguishing feature of such siding, there is a rounded section of the panels with a profile height of about 4 cm. Such facade panels with a characteristic texture of wood are equipped with special decorative corners to imitate the log cutting. The house lined with this finishing material looks exactly as a log cabin, moreover, such a cladding allows you to "breathe" the walls.

Laminated wood siding is a panel consisting of a plastic base with a special film applied to it that imitating wood texture with characteristic irregularities and pattern. From above, such panels are covered with a laminating protective layer, which gives it a glossy shine. Such a finishing material is highly resistant to adverse weather influences.

For the manufacture of acrylic siding under a tree, a new generation polymers are used, characterized by high burning resistance under the influence of ultraviolet rays (several times greater than the vinyl counterpart), as well as stability to deformation. The acrylic siding panels are distinguished by a very durable glossy surface, on the form indistinguishable from the natural tree and preserving shockproof properties for a long time.

Montage of siding under the tree

Lower the facade siding under the tree on their own quite real. In order for such a finish to serve as long as possible, when it is installed, it is necessary to take into account some features of working with this material. To exclude the deformation of the cladding under the action of temperature drops, it is necessary to mount the panels, so that they overlap each other at least 3 cm. In addition, it is not possible to leave the gaps with the angular elements of about 5-6 mm.

For cutting panels, it will be necessary to prepare a sharp knife, electrical cooking with small teeth or a grinder, in addition, you can use scissors for metal. It is possible to cut them as follows - make a neat suction with a knife and breed the material, bending the panel on the intended line. When siding siding scissors to use only part of the cutting blade - in this case, the cut will be as smooth as possible and smooth. Bulgarian for cutting is recommended to use purely on small revolutions, otherwise the edges of the panels can be melted and they will have to be cleaned.

Sequence of work

Before mounting siding, it is necessary to remove the branches of the trees and shrubs located near the construction, dismantle the protruding details from the facade - doors, lattices, as well as shutters, lanterns, platbands. In addition, it will be necessary to clean the surface of the facade from garbage, dust and mold, consider peeling paint and plaster to obtain the most smooth and durable surface of the facing.

If you plan to install the panels on the walls from the bar or lining, you should replace the downloading boards and fasten riding with the help of screws. In addition, it is necessary to check how smooth is the base surface under the finish. When identifying a significant difference, it will be necessary to align it.

To favors the brick or concrete surface of the walls, it will be necessary to pre-establish a durable frame from wooden bars or a metal profile, following the distance between the planets of the crate of 30-50 cm, depending on the length of the walls.

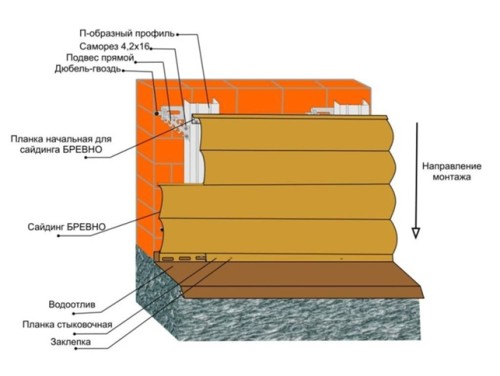

Next, it is necessary to determine the zero level from which the installation will begin - the panel is required to mount at the same height. Siding installation under log differs from the installation of conventional vinyl siding by the presence of a n-shaped profile, which fastens them together on the joints.

After preparing the basic surface of the siding panel, it is necessary to consistently fasten with nails, starting with the back of the building - it takes that their caps are not slightly reaching the siding level (with a gap of about 1 mm). In addition to nails, the mounting panels can be carried out with the help of a construction stapler or screws. It should be noted that for external work it is necessary to choose aluminum or galvanized fasteners.