The construction of cabins at the construction site is one of the main stages that precedes the start of common work. It usually stores tools, expensive materials. It can also serve as a temporary room for the placement of the builders team (more often they are built). Some cabins after the end of construction simply disassemble, some remain on the site as the construction of economic purposes.

Content

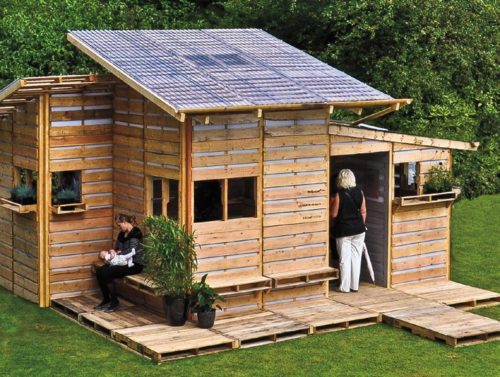

Since the domestic can not be considered a permanent residential premises, the requirements for its construction are somewhat lower than for a residential building. Therefore, simple designs are completely for the power to make with their own hands, not even having special construction skills. Even waste, such as used wooden pallets, can serve as construction. About how to make food from pallets with your own hands - further in the article.

Types of household and their appointment

In order to choose the most optimal material and design of the cabinet, it is necessary to determine its purpose:

- Instrumental. Calves, the appointment of which is only the storage of tools and building materials. Constructed from any submitted means: hill, unedged boards, pallets, etc. The advantages of the wooden cabinet is primarily in its price. There may be no window in such a design. Its building is not economically profitable, cheaper to carry electricity and put the lantern, anyway, a person in such a structure will be only from time to time. No requirements for heat saving are not presented to the tool forces, since for housing people they are not intended and installing heating devices in them.

- Residential. Must have a stronger design, wall decoration without cracks and with the mandatory use of insulation materials, if it is necessary to live with a decrease in temperature. More qualitative materials are needed for the construction of such a household. Its decoration is more often carried out using OSB, professional flooring or siding using insulation. When installing inside the bourgearium or electrical heater, the materials of the finishes must pass the mandatory fire processing. Also in such households set minimum one window for the organization of natural lighting. As a rule, residential households after the end of the construction of the main house are disassembled, and organize baths, workshops, summer houses or houses for guests.

- Mobile. Most often used by the builders-professionals for operational transportation to objects. Constructs most often from wood and steel on the chassis of trailers. The most popular material for the construction of mobile cells is a sea container. After a small alteration, it turns into a full-fledged place for recreation or tool storage. Moreover, it is easy to put on the platform (it has standard dimensions) and transport to the required place. For independent construction, the construction of such a type of location is not effective.

Construction of cabins do it yourself

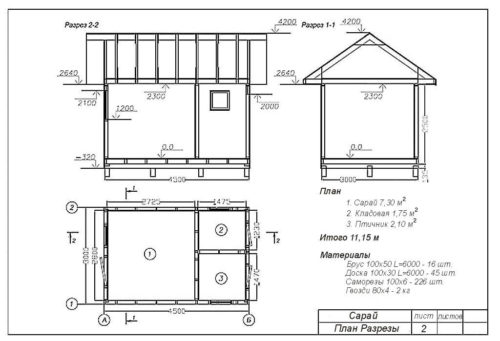

After selecting the type of structure, which will be built, it is necessary to make a drawing of cabins from pallets, in which it is necessary to display its dimensions, the type of foundation, the roof type, the presence and size of the window, doors, etc. The drawing preparation will help determine the required amount of material and step-by-step sequence of work.

Standard plan for the production of work on the construction of cabins Next:

- Construction of the foundation.

- Construction of the frame.

- Installation of the roof.

- Frame covering with finishing material.

Construction of the foundation of Motovka

Taking into account the fact that the wooden frame building has not a lot of weight, the powerful foundation is not necessary for it. Most preferred for this type of structures are 2 types of foundation:

- Monolithic.

- Column (pile).

The monolithic foundation is more preferable compared to the pile. It is suitable for a large soil spectrum, which makes it more stable. In addition, the structure on the monolithic foundation does not require the laying of powerful genital beams (Lag). However, it should be noted that the cost of the construction of such a foundation is much more expensive compared to the pile.

Procedure for work:

- The construction of a monolithic foundation begins with a digging of a small pit, whose depth is only 200 mm. It is quite enough to withstand a frame wooden building. Typically, the foundation is located in the corner of the site away from the entrance gate, so as not to interfere with the travel technology to the main area of \u200b\u200bwork.

- The pillow from sand and rubble is stacked on the bottom of the pit. First, the sand layer is mounted, then rubble. After laying each of the layers, it must be carefully tumped.

- After the pillow is tamped, you can start the formwork. Its height should be slightly larger than the planned foundation height. For the formwork device, you can use boards or waste chipboard.

- To fill the foundation, it is necessary to establish a reinforcing layer. Otherwise, he may simply crack. A belt is made from the reinforcement or rod with a diameter of 6-8 mm.

- After that, you can pour concrete. It is made from a mixture of sand and cement in the proportion of 1: 3. It is advisable to spend the fill when the street is warm on the street (not hot) dry weather. If it is too hot, moisture from concrete will quickly evaporate until it has time to gain strength. This can lead to its cracking.

- Before concrete completely freezes, the anchor bolts should be installed to which the lower beams of the frame will be installed.

How to make a frame for cabins with your own hands

This is the most responsible moment, because the strength of the whole design depends on it.

Procedure for work:

- The first thing for the foundation is installed by the waterfront timber (bottom beams). So that the tree does not pull moisture from the concrete, between the bars and the foundation it is necessary to lay a layer of waterproofing (most often running runway).

- On the perimeter it is attached to the foundation with the help of anchor bolts. The bar is drilled by holes, a diameter of equal to the diameter of the bolt, and sue the nut with the washer. In the corners between each other, the bars are connected to the castle. When installing the base, it is necessary to clearly exy the angles between the bars, they must be located strictly perpendicularly.

- When the lower bars are installed, you can start the mounting of vertical racks. They are installed in the locks in the junction of two base beams. When installing a vertical rack, it is necessary to check its vertical in the level, after which it is fixed at the base using steel corners.

- In order for the vertical racks did not deviate from their position, they can be strengthened with disconse-diagonal beams, which will connect the upper part of it with the base bar.

- When all angular racks are installed, they are connected to the upper crossbar.

- Now you can build the framework of the walls of the cabins from the pallets to which its covering will be attached. As a sheat, it is advisable to use boards from old euro pallets. They have standard length, width, thickness, which will reduce the cost of time to prepare wood. In addition, this material is quite cheap.

- For the production of pallets, a board is 1200 mm long, 100 mm wide (2 pcs per pallet) and 145 mm (3 pcs per pallet) and a thickness of 30 mm. That is, from one pallet you can get 6 m boards. If the boards length is 1200 mm, then the distance between the colones should be no more than 600 mm so that one board is attached to 3 racks. Racks are attached in the same way as corner supports.

- For the door and windows, an additional design is constructed.

Setting the roof frame

For wooden cabins from pallets, the most suitable will be a bartal design.

It is made quite simple:

- The first thing in the center of the front and rear crossbar (it still has the name of Mauerlat) vertical racks are installed, which is stacked by the ski beam. It is toward it that rafters are attached. Fasten the latter is necessary so that the place of the connection accounted for the column. Special corners are attached to the crossages of rafters using wood screws.

- The angle between the beam and the rafter should be the same on the whole roof. The installation of the rafter should be constantly checked, since at large deviations to establish the roofing material will be problematic.

- The decoration of the roof of cabins is better to produce lightweight materials, such as professional flooring or bituminous tile. Special scrupulousness in the laying of roofing material is not required.

Exterior finish of cabins from pallets

The covering of the finished carcass will not be much difficulty:

- Boards must be carefully disconnected from the pallet so as not to split them. Usually pallets, which are no longer suitable for moving goods, have not too high-quality wood, so the boards are better to view and sort.

- After that, they need to be covered with antiseptic material. The easiest and cheapest material is Olife.

- After opening the boards, they give dry and begin to nail to the frame. Do it better from below-up. If the household is planned to be disassembled, then for fasteners use nails with a length of 80 mm, if not - you can take a self-tapping screw. In this case, first a hole is drilled in the board, and then screwdriver screws up into it.

- The last stroke in the walls of the walls will be painting. The internal finish of cabins can be carried out with the help of DVP sheets, putting a layer of insulation under them.

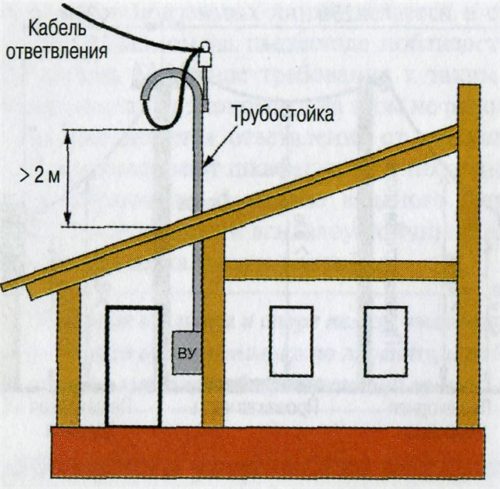

Sweep electricity to the household: photo