The concept of "foundation" is familiar to every person, this is part of the construction that takes on the load, and then transmits it to the base. We do not see this part of the building, it is underground. Relying on the foundation for the base or dense earth ground. From how correctly the construction technology is observed, the final result depends. If there is a need to strengthen the foundation of the building, then you need to install a collecting tape base.

Content

What is a belt foundation

Let's first figure it out with a concept that such a foundation is to understand its meaning. So, if you look at the support, that is, the foundation, its upper plane serves to mount the ground part of the structure. This part is called a crop, and the lower (non-visible), which comes into contact with the Earth or another base is the foundation sole. Ribbon foundation is a band of monolithic reinforced concrete, located around the perimeter of the structure. The tape must be laid under the outer and inner walls of the construction to preserve the shape of the cross section throughout the perimeter.

The technology of a collection of ribbon foundation is a simple solution. If you compare the installation of monolithic blocks by another type of foundation, it is possible to cope with the task itself, if we are talking about the construction of a one-story building. Despite the ease of installation, when installing the finished structures of prefabricated belt foundations, there is a need for additional equipment. So, without attracting a lifting crane, it is impossible to cope with the construction. In addition, it is worth considering that in addition to the high laboriousness of the work, you need to immediately be ready for large consumption of building materials. It will take a lot of formwork and cement.

Application area:

- when building a brick house, concrete or stone. Requirements for wall density - up to 1300 kg per 1 m 3;

- when building buildings and structures from precast concrete structures, as well as from monoblocks;

- in the event of a threat of uneven load distribution or if the soil on which the foundation is installed is inhomogeneous. As a result of the edge of the belt foundation, you can count on a uniform load distribution. If this is not done, the walls can give shrinkage: crack, but over time and deform;

- if the plan in the house will be built the ground floor or basement. Just the walls of the ribbon foundation will replace the walls in the basement.

If at the initial stage does not comply with all the rules of construction and save on construction materials, then large problems may arise during the operation of the building. For example, over time, the foundation begins to deviate to the side, horizontal and vertical structures are deformed, cracks appear. From how high quality and reliably the foundation is set, the duration of the operation of the building depends. Therefore, given the fact that the construction of the building from scratch will require certain knowledge, skills and consumption of materials (the third part of all expenses is allocated only to the preparation and installation of the foundation), this work is better to trust the specialists.

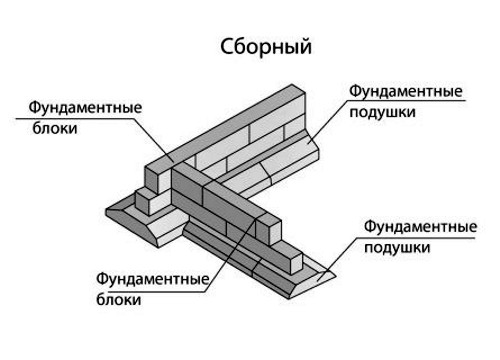

This is what the predatory ribbon foundation looks like from blocks.

If we consider the duration of operation of different types of foundation, then such conclusions can be made: blocks made of concrete monolith or a tape fundament from a cement solution will last for more than 150 years, the foundation from the brick ribbon will serve no more than 50 years, and the precast concrete foundation can be at anex to 75 years old . Based on this, it is possible to make this conclusion: the most secure and durable design is the ribbon precast concrete foundation.

Device and types of foundation

The design base structure is divided into such types:

- monolithic;

- combined;

- prefabricated.

By type of device, a ribbon foundation can be solid and intermittent, and in the form in the form of a rectangle and a trapezium.

According to the rules for the construction of buildings and structures, the ribbon width of the foundation should not be less than the width of the wall, which will rely on this foundation. It turns out that the thickness of the wall may depend on the thickness of the ribbon foundation.

Read more about:

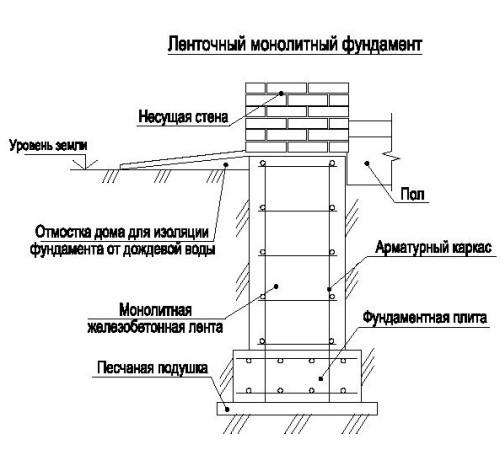

- Flusted or monolithic foundation - it is made on the construction site. This is a single strip or tape. The principle of manufacturing a monolithic belt foundation is simple: a doom is prepared, into which the liquid solution is poured. As soon as it hardens, it turns out a continuous solid base. To give the structures of strength, fittings are installed before the cement filling in the crate. The feature of the foundation of this type is the installation of wood formwork. You can immediately set the desired form of a future tape foundation from those materials that do not allow spreading of a liquid solution (metallic, plastic or wooden formwork). If necessary, the crate can be left or disassembled. The features of the monolithic foundation are that only concrete solution is performed as the main material to be pouring into a pre-prepared formwork. In addition, it is necessary to clearly adhere to the temperature regime, laying technology and further operation. Of the advantages of such a design, the increased strength of the structure, durability and reliability can be distinguished.

- A collection-monolithic ribbon foundation is collected from finished blocks, which then need to be connected to each other with reinforcement and secure cement mortar. The principle of structures: on a compacted and even base (earthy pillow, a mixture of land with sand) stacked blocks with a displacement (construction technology - stacking of seams). Connection locations for reliability need to be reinforced. Such tape blocks are used to build single-storey buildings. Externally, the foundation looks exactly the same as the monolithic, only it is divided into several elements that are securely bonded. This is the main lack of a ribbon basement. In addition, there are difficulties in fitting some elements for the size of the foundation in each particular case. Sometimes during construction, you can encounter the fact that the factory block does not fit and you need to divide it. In order not to engage in extra work, fill the emptiness to liquid concrete faster or put brickwork. Among the benefits of work with such blocks, you can allocate: the accelerated deadline for construction, the ability to work in the cold season, there is no need to use heavy special equipment, suitable for building structures with basements.

Ribbon national foundation. Drawing:

- Combined belt foundations are a combination of materials and forms of products. It is used when you need to raise the building level, when building buildings on slopes or complex soils. This option is not popular due to difficulties in the work, the high cost of materials and reducing heat indoors.

- In the process of building the structure, it is necessary to pick up the building material in size to adhere to the specified form. Making this type of foundation is very difficult and time consuming. The work takes a lot of time, you have to manually pick up stones. There are positive aspects: the foundation will last for many years.

- Ribbon foundation from concrete and fine butte stone. The technology is somewhat different from the construction of a boob foundation. Prepare the crate, pour out the shallow gravel and the cold cement. The composition of the foundation: Half of the concrete solution, half of the stones. Features of the work: There is no need to select the stone of the desired form, lay the layer of stone - poured with a solution, again the layer of stones - the solution.

- Brick foundation is the same brickwork on cement mortar. For the construction of such a belt foundation, a durable brick with water-repellent properties is used. This type of foundation is used only on dry soils and for the construction of single-storey buildings. To extend the life of a brick belt foundation, it is necessary to choose a good building material - it must be burned brick. It is impossible to use silicate, as it is quickly destroyed.

DEVICE OF THE BRANCH FOUNDATION

During the work, it is often necessary to fit - this is the place of compounds of the outer wall and interior. Then the workers have to customize blocks for size right in place or fall asleep emptiness by any building material. It is important when installing the ribbon national foundation to take into account the size of the structure and lay out blocks sequentially in advance prepared recess.

Usually when laying ready-made blocks is used heavy machinery (lifting crane). It is inconvenience during operation, since it is not always a crane when placing blocks copes with the tasks. All the subtleties need to provide in advance. Suppose that if the area of \u200b\u200bthe future building is large, then you can do otherwise. In order for the crane to get to the object and lay out blocks in a given sequence, you need to prepare the trenches for stacking blocks in stages. So, you first need to make marking and stick to these rules in the future.

You can lift the blocks with slings, the crane lays the block at the installation site, turning and lowering in the trench prepared in advance. Then that the next unit be laid as accurately and close to the first one, you need to install checklines. To do this, with the help of a construction plumb, it is necessary to align the horizontal blocks and continue laying the ribbon foundation.

If inaccuracy is detected when laying, then the deviation data must be immediately eliminated - to set the following block by level and continue the work. It is possible that during operation you will have to straight blocks manually. Prepare the tool - "plant" a block into a cell will help scrap.

Installation of the Band Foundation

Stages of work:

- First you need to prepare the area under the foundation: to clear the site, to ride the necessary building materials, perform marking. The last item must be observed as accurately as possible. To make the markup correctly, prepare the rope (wire you can) and pegs.

- We prepare the trench - we take out the earth and equip the place. If you build a foundation without formwork, then concrete can be pouring directly into the prepared ditch. Its width should be the same with the estimated width of the tape basement. You can manually pull the trench or attract specialized technique. After the trench is prepared, the place must be cleaned and dissolve. Now I am preparing the basis: it will be a thin layer of sand (up to 2 cm) or a small stone that needs to be thicker. On the resulting "pillow" lay waterproofing material and poured with a solution. The waterproofing layer is necessary, otherwise the liquid will go to the ground. When the base is made of stone or brick, then the pillow must be reinforced with the cement solution.

- How to install formwork. We prepare the frame inside the trench of the tree (the board with a thickness of 5 cm). To fix the formwork, use wedges or spacers. Do not forget to observe verticality and fix the upper part of the formwork in addition to the straps. The height of the construction of the frame for the fill of the belt foundation is within half a meter from the ground. This will be the base of the future facilities. Watch the boards to be laid close to each other without cracks so that the solution does not proceed. You can from the inside to lay the formwork with an additional layer of waterproofing material. If you pour a solution directly to a wooden formwork, then the tree needs to be carefully moistened with water so that the concrete solution does not have time to absorb.

- Laying of reinforcement - rods need to be assembled in advance in the frame and combine each other (we use the wire or welding machine). According to the height of the foundation, put the reinforcement. The result is a monolithic block.

- Pour concrete into a formwork. We fill the first layer of cement mortar, a thickness of 15 cm, tightly tamper to remove air bubbles and evenly distribute the mixture. It is important to make the solution properly so that it fills all empties well. Between the fills it is impossible to take breaks, as the concrete will begin to be captured.

- Laying the layer of waterproofing. As soon as the cement solution is completely dry (10-15 days is given to it), you can remove the formwork. So far, the strength of such a design is not higher than 70%.

- Failure of emptiness. The remnants of the Earth can be used as a sub producer.

It is important to adhere to these rules:

- if you have prepared a trench, it is impossible to slow, as it will begin to collapse due to precipitation;

- while the cement is captured, you can cover the upper part of the foundation with an insulating material (for example, dense polyethylene). This will help protect the foundation from trash and precipitation;

- to take extra water, around the foundation you need to build a breakfast.