Film warm floor is the best way to device additional and local premises. Such a system is economical and convenient to use.

Content

In addition, the technology of laying film warm floor does not require special preparation and use of complex tools. It is enough to familiarize yourself with the rules of installation. But at the beginning about the benefits of such heating:

- the cost of the warm floor of the film several times less than other heating systems;

- laying the film forces can be carried out directly under wooden finish coatings without the risk of damage to the material during operation;

- lack of electromagnetic radiation;

- installation is possible without reducing the height of the ceiling;

- low electricity consumption;

- local damage to the film does not affect the performance of the system.

What is necessary for work

Installation of film warm floor can be started with the following equipment and tools:

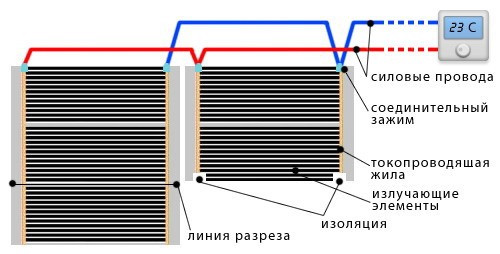

- film heating element;

- connecting wires;

- protective shutdown device (UZO);

- grounding cable;

- fasteners;

- thermal sensor and automatic regulator.

Planning a heated surface

Initially, it is necessary to properly distribute the film warm floor on the heated surface. The instruction prescribes not to lay the film where massive furniture will be installed. In addition, you must follow the following rules.

- It is necessary when laying the film to distance themselves from the risers of central heating systems, pipes and heating boilers. This is necessary in order to avoid the failure of heating elements under the influence of high temperature.

- Before starting work, it is necessary to develop a scheme of laying a film underfloor. On a rectangular sheet of paper, the wavy line should be noted the styling zones of the infrared heating element.

- To accommodate an automatic thermostat, you need to select a plot on a wall that is not finished with furniture or heavy curtains.

- For neighboring premises and zones located on a common area, it is recommended to plan the installation of independent systems from each other, with separate regulators and connections to the electrical network.

- After laying on paper, the scheme is transferred to the floor surface. To cover the area, the required number of elements and connecting wires is selected for connecting the thermal sensor and the regulator.

- It should be borne in mind that the width of the film warm floor can be different: 50, 80 and 100 cm. It is sold by rolls that can be cut in certain places. There are various types of film warm floor: Power depends on the characteristics of the film (150, 220 or 400 W / m²).

Preparation of the basis for film laying

The installation of film warm floor begins with the preparation of the base. This is performed in several stages. Thermal insulation is stacked. The choice of material for this is carried out by this principle:

- To compensate for thermal expansion along the walls around the perimeter of the room, a damper tape is mounted.

- The waterproofing material is stacked (rubberoid, only or thick polyethylene film) with a nasky about 150 mm on the wall.

- The screed is examined: if the quality of its surface does not meet the requirements (in the presence of a plurality of cracks, depressions, etc.) - the screed will have to dismantle.

- The old coating is dismantled:

- in the event that the infrared film floor is not the main heating system, over the base, foam polyethylene foaming upwards (so thermal energy will be reflected in the direction of the room);

- if there is a heated room at the lower level, polystyrene foam plates with a thickness of 30-50 mm are used as thermal insulation material;

- when installing the film on the unheated loggia, the thickness of the polystyrene is increased to 100 mm.

6. The next layer is the reinforcing grid. Without it, you can do if the layer of the screed will be thicker than 50 mm. You can achieve the necessary strength using microfiber and plasticizer.

How to lay a film warm floor

- Connecting a film warm floor to an electrical network is performed by a wire, a cross-section, material and insulation of which is indicated in the manufacturer's passport. The required type cable is kept from the switchboard (where it connects to a separate "machine") to the installation site of the thermostat.

- In the event that the infrared system is mounted in the bathroom room, the reinforcing mesh under the tie is grounded. Grounding is connected to the thermostat with copper wire. Mandatory in the shield set the Uzo (current current - not more than 30 mA).

- The thermal film is placed on top of the screed, the surface of which should be smooth. Film contacts oriented towards the thermostat. Rolls roll along the long room wall to reduce the number of connective wires.

- The film is fixed for special ears or scotch to the ground to eliminate its move when laying outdoor coating.

- All thermocons contacts are connected using soldering or with rivets to the copper strip. Subsequently, contacts are isolated.

- On top of the film, a polyethylene film with a thickness of at least 0.5 μm is fired. Neighboring bands are stacked with the allen and connect with scotch.

- Where the wire crosses the lines of docking the adjacent slabs of the overlap, it is protected by the segment of the corrugated pipe. This will ensure the integrity of the cable with a thermal expansion of concrete.

- For an embedded regulator in the wall with the help of a perforator and the crown, a non-through hole is dried from the floor to the floor. A corrugation is lit into the stroke, according to which the power cable and the cable from the thermal sensor are packed. Everything must be arranged so that the thermal sensor can be replaced in case of damage.

- The wires from the thermal sensor and the circuit breaker in the shield are connected to the terminals specified in the operating instructions.

Important: The total capacity of the film strips should not exceed the power of the thermostat.

We offer to familiarize yourself with the video "Installation of warm film floor":

Precautions during installation

When installing infrared warm floor is prohibited:

- work under conditions of high humidity and at temperatures below zero;

- bend the film at a right corner;

- allow overlapping floor bands;

- prick strip with sharp objects;

- lay the segments exceeding 10 m in one piece;

- allow current consumption by one segment over 10 A;

- connect the film rolled into the roll;

- cover the thermofilm with metal sheets;

- film with furniture, dense carpet, stack it near other heat sources.

Important: When flooding the room with a warm film floor, it is necessary to wait for the complete drying of all surfaces. It is prohibited to enable heating and dry the floor with a heating film.

In the event that the film was pushed with a sharp object, the damage place should be isolated from both sides.

System performance checking

After the installation is complete, it is necessary to check the film warm floor. Question price is the efficiency and safe operation of the heating system. Experts recommend on the chain to check all contacts using the voltage indicator. It should be verified that all contacts are securely isolated. After the heating elements are covered with the film, you must perform a trial switching on.

If everything works fine - the first floor covering is stacked: laminate, parquet board or linoleum. As a result, get a film warm floor, reviews about which you can read on the Internet.

In conclusion - how to choose a film warm floor (video):

Thanks for the article, a very good article. All is outlined.