The foundation of the structure is an extremely responsible structure, on which not only the total strength and stability of the structure, but also the durability of the construction structure depends. There are many examples of how errors made by creating a foundation have created colossal problems for the construction. In this case, we are talking about serious financial losses, since low durability will not allow to exploit the building for a long time. It is also interesting that in some situations builders are trying to save maximize on the purchase of building materials, and this leads to large-scale problems.

Content

As for the direct basis of the strength and durability of the foundation, then often we are talking about the use of reinforcing funds. With their help, the foundation that may be erected on the basis of not the best brand of concrete will be truly durable. The specialists noted that the correctly selected reinforcement saves a significant amount of money, and first of all it refers to the absence of need for further repair activities.

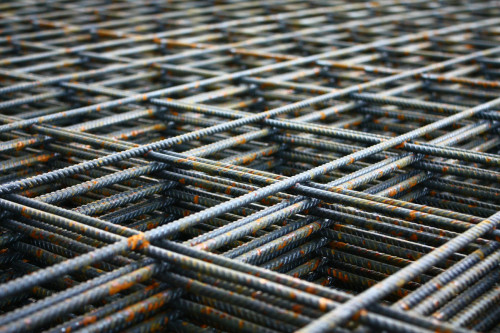

The most common reinforcement is the reinforcement, which is applied in construction for many decades, but still has not lost its relevance. This material is a private rod, which create a solid metal component.

In this article, we will analyze in detail the question associated with stacking fittings in the foundation. It is worth understanding that this is a responsible question, but everything can be done with your own hands, but before that it is advisable to study the technology in detail so that each subtlety of the process remains unnoticed.

Features of the use of fittings

As we have said, the reinforcement is a component of a foundation, which significantly strengthens the overall design of the foundation of the house or other construction. If you create a foundation without reinforcement, it does not have to wait for particular reliability from such a base, even if the concrete design itself has no exaggeration of giant dimensions.

By the way, the construction of a wide variety of reinforcing agents is now in construction, and it all depends on what conditions the structure will be used. For example, a microfiber has been used lately, which not only strengthens the concrete structure, but also makes it more adapted to various vibrations and other influences that are often perceived by the foundations.

It is important to note the fact that much depends on the reinforcement scheme. This suggests that the presence in the concrete structure of metal elements is practically nothing. Within many years, the construction industry analyzes the most optimal use options for the use of reinforcement, and are now known as efficient schemes, allowing you to extract maximum benefit from the volume of concrete and the number of reinforcement.

Directly the reinforcement process takes place before the fill of the frame of the frame concrete, so it is necessary to analyze all the features of the future building in advance so that the hardening elements used for the project.

Materials required for work

As we have already mentioned, the process of building the foundation is an extremely responsible event. Moreover, it should be borne in mind that every detail, even that, which at first glance does not have much importance, can seriously affect the overall process. Worst of all, if this part of the reinforcement is concerned, since due to low strength, the entire structure may be unsuitable for further use.

Thus, if we are talking about materials, you should have a whole list of construction products, which will allow you to spend the whole process without unnecessary suspensions and other unnecessary parts.

- First of all, fittings need. Moreover, experts note that in the process of reinforcement, 2 types of reinforcement will be used. The first view is the rod fittings, which is the basis of the reinforcing design. It is obvious that these very pins should be located vertically and horizontally, and further the addition of other elements will come. The second type is the reinforcement wire that will perform a binding function for the design. Already at the stage of acquisition of the rod fittings, the total amount of material necessary for high-quality reinforcement should be known. The calculation should be fairly accurate, since, depending on the scale, there will have to spend a lot of money. Do not forget that there should always be a little material about the stock, especially if we are talking about the most important resource for hardening the design.

- The wire is a solid material that is able to associate and ensure the integrity of the largest metal structures. The diameter of such a wire is about 1.1 mm. Specialists advise to make a choice in favor of plastic wire so that there are no problems with the compounds at all. It is also worth saying that a small plastic wire creates a lot of problems, and above all they are associated with a rupture of the material. It should be borne in mind that the reinforcing design itself may not be too stable, therefore, it is impossible to exclude problems associated with the overall integrity. It should also be borne in mind that when pouring concrete, the reinforcement can start changing its position, and in such a situation it is necessary to do everything possible so that the carriast keep everything in the initial position. Obviously, if deformation occurred during the fill, it means enormous problems, especially if the foundation is large.

- Metal pegs. These elements are necessary for the most optimal markup of the site. Practice shows that the construction is best to qualitatively analyze the question associated with the location of the future design, and only then you can make some conclusions.

- Construction roulette. In the process you need to make accurate measurements that will create a design that makes the most appropriate project parameters.

- Sledge hammer and hammer.

- Welding machine. In the process it will be necessary to weld the frame of reinforcement. It is obvious that the process itself is hardly done, if there is enough experience, however, you can always find experienced welders who will spend the entire amount of work for small money.

- Grinder. It is often happening so that after the fill, the foundation design has some curvature. This is a common situation, and it is not worth treating it too serious. It should be noted that with the help of a grinding machine, all disadvantages of concrete design are easily minimized or disappeared at all.

Preparation of carcass

Immediately after all the necessary materials were purchased, and the situation was analyzed, we can safely begin to create a reinforcing frame. It is obvious that at this stage there must be a plan, on the basis of which reinforcement will be created.

It is also worth deciding on the frame creation scheme. First of all, this refers to the reinforcement of the corners of the future concrete structure. The first option is based on the reinforcement of the corner of the brass with a paw, and the second method implies the reinforcement of an angle with a M-shaped clamp. It is worth noting that the first and second options can be applied in various conditions, but it is necessary to globally consider each project and make specific conclusions.

It is most important to remember that the reinforcement should be located at a distance of 6.5 cm from the parties of the future concrete structure. It is impossible to allow concrete after the fill with concrete, the armature peeking out of the design. If such an error is allowed, the effectiveness of reinforcement will be at a fairly low level. In addition, it is noted that due to improper placement of the reinforcement, the waterproofing of the foundation will significantly affect. In some situations, for example, when the base is located next to the groundwater, unwanted processes may occur, which should be made as early as possible.

Laying of reinforcement begins with the installation of basic rods, which are located at the top and bottom of the foundation along the entire length. The overall design width should be based on 3-4 elements - this question depends on the size of the foundation, as well as on the overall specifics of the future structures. Specialists advise not to use less than 3 rods on the one hand, since otherwise the strength of the design will be under a big question. A serious impact on the situation is created aspects such as sending and swelling.

Next occurs a frame assembly from reinforcing wire. With the help of this material, P-shaped elements are created, which are built into a row and create a kind of tunnel for the arming. These elements should be about 10-12 cm below than the overall foundation height. As for the width, the situation is approximately the same. Experts advise to make such assemblies in separate places, which will not feel any restrictions and inconveniences that usually arise when creating reinforcement. Already after everything is manufactured, the design can be safely used in the foundation area. By that time, the frame should be the most corresponding to all the necessary parameters.

Armature belt armature

- It all starts with fittings devices at the bottom of the foundation. First you need to place the figures about which we talked earlier. At the same time, it is important to place all these items in such a way that no difficulties do not happen. We are talking about the distance from the edge of the foundation. Near each figure, with the side part, metallic pegs are inserted, to them, with the help of a wire, you need to tie the figures. This will make the design is really durable and reliable.

- The second step is the laying horizontally in two reinforcement rods. It is worth noting that the lengths of the rods should be enough to enter the figure. At the bottom of the foundation for fastening metal elements occurs with welding. It is worth paying attention to the fact that the welding of one reinforcement is advisable to spend in three places, as this will provide the necessary level of reliability. Inside each figure, two rows of rods are welded to the side racks. To do this, it is advisable to use the reinforcement wire. This is how the bottom belt is created.

- Next follows the top belt of the foundation. Everything is almost similar here, but you need to keep in mind that everything starts with the top of the foundation. After these works, it turns out a solid belt, which is associated with rows from above and below.

- The final stage is the most time consuming. Here we will need the help of third-party people, as one handle it is unlikely to manage to cope with the task. We are talking about placing a metal structure into the formwork frame. As we have already spoken, the frame is best to create separately from the foundation, and the negative side of such a decision is that a full-fledged installation should be carried out later. It is noted that for the frame it makes sense to create a base that will consist of large stones. The layer should be about 6 cm. It is worth noting that such a solution allows the most reliable way to make the creation of the very gap, which should be between the reinforcement belt and the foundation. Also, do not forget about the intervals between the edges of the formwork, the distance is approximately 6 cm.

Final work

Already after the installation of the reinforcement was made, the binding of the segments sticking from above should begin. For this, the knitting reinforcement wire is used, which is characterized by some plasticity. Experts advise to produce strong and durable obscenities, as a large wave can be created when pouring concrete, seriously affecting the integrity of the design. Ultimately, the reinforcing design will be somewhat dismissed that it will question the situation associated with the overall strength and reliability of the foundation.

Some specialists do not deal with wire ligament, but simply weld the ends. Such a decision also has the right to exist, but it should be borne in mind that in the framework of small foundations there will be quite enough and normal binding. Ideally will make a bundle, and then set the ends of the welding. With this scenario, the belt will gain optimal strength.

Processing of reinforcement in the corners is the final part of the work. The task is that it is necessary to bend the units of reinforcement so that the angle is approaching 90 degrees. Of course, the perfect corner is not always easy to achieve, but it is worth attaching the maximum effort so that this value is. It is now important to connect bent ends with pins, located crosswise, while fixing each separate connection with four or more knitting wire twists. Obviously, everything is based on the reliability of the compounds, so this question should pay maximum attention. Again, if the construction will be small, then the requirements for the foundation are not too serious.