To strengthen the concrete foundation, prevent it with damage and deformation, resort to such a procedure as reinforcement. For this, inside the concrete strata create a frame of metal fittings. In this article, we will consider in detail what is the reinforcement of the foundation of the grid.

Content

Functions and Face Features for Foundation

Foundation reinforcement is an important operation that is necessary for several reasons:

- The foundation grid allows the design to preserve its form.

- Metal bars strengthen concrete, as a result of which it does not destroy under the influence of uneven physical exertion.

- The reinforced foundation does not seek over time under the severity of the construction.

- The foundation grid also takes on tensile loads with which the fragile concrete is not able to cope.

The diameter of the reinforcement, the sizes of the cells, the method of fastening the elements should be calculated at the stage of designing a concrete base. In the process of creating such a project, it is important to take into account several quantities:

- soil features on the plot;

- the magnitude of the load on the building;

- the depth of the future foundation and others.

The price of a grid for the foundation will depend on its diameter and characteristics - this information is in the marking of the goods. You can associate fittings yourself, observing a number of recommendations:

- The size of the mesh cells can vary in the range of 15-25 cm.

- Metal bars are desirable to choose corrugated, as they are better to close with concrete. Corrugated rods include hot-rolled rods of A2-A6 classes.

- In the process of work, it is better not to use pruning of rods, because they are joined with a large overlap, and this leads to the overflow of the material.

- Fixed with each other you need at least half of all grid intersections.

- It is possible to make a welded grid for the foundation only from the fittings with the marking "C". Moreover, if its diameter does not exceed 25 mm, then the welding is carried out by a point method. Thicker parts are welded with an arc way.

How and how to knit reinforcement grid for foundation

The reinforcement grid can be made directly at the construction site in the process of laying the foundation. To fasten the elements, the wire is used or plastic clamps. In principle, you can purchase the finished reinforcement grid for the foundation, but it will be somewhat higher. Such a framework is carried out by flattening the rods without welding, thereby achieving the reliability of the joints.

Consider ways of self-creating reinforcing mesh for the foundation:

- The first method involves the use of soft and flexible wire, which is made from low carbon steel. If the wire is neat enough, it is heated for half an hour, and then cool. For mating reinforcement, both galvanized material and non-zinc. The last option is cheaper, but is not protected from the harmful effects of negative surrounding factors. The diameter of the wire, which is used for such a work varies in the range of 1.2-1.4 mm. Before starting the process, the material is divided in advance to fragments of 10-20 cm long.

- Another way to fasten the masonry grid for the foundation involves the use of plastic clamps. This method is faster and easier, but not all builders risk resorting to him due to the fact that they do not have one hundred percent confidence in the strength of plastic. There is evidence that such clamps do not tolerate severe frosts and can burst, and they do not apply them in the construction of large buildings. Plastic clamps can be used to fasten the rods during the construction of small houses, arbors, as well as for fixing the elements of composite reinforcement.

Methods of mating reinforcement grid also have several, they differ in the type of tools used. For bonding rods apply:

- pliers;

- nippers;

- special hook;

- knitting gun.

The pliers and pliers are suitable for the implementation of the simplest way to knit reinforcement. In those places where the rods are intersecting between themselves, the wire will be crumpled from below and twisted its free ends one of these devices. Sticking fragments are bending, so that they do not drank out.

Hooks for fixing metal rods can be purchased at a finished form or make it yourself from very durable and thick wire. During operation, the wire is cut into parts, fold them in half, making a loop from the bend and entering the hook into it. The ends of the wire are at the intersection of the reinforcement and bend over the hook. Then the wire is twisted until reliable fixation is achieved.

The hook can be twisted in several ways. For example, with an ordinary crochet, it is done manually, which is long enough and not very convenient. If the grid is created using screw hooks, they are twisted by pressing the handle. The fastest method will be the use of a screwdriver or drill, in the cartridge of which the hook is inserted.

During the construction of large buildings, the process of binding of reinforcement should simplify the maximum and loss, a knitting gun is used for such purposes. It has different quality and is different in price. So as not to overpay the extra, but not to throw away the tool after completing one object, many prefer to buy a high-quality used gun or take it for rent. Such an adaptation is convenient to fasten the reinforcement in open places, but in hard-to-reach zones you have to do with other tools.

In the process of operation of the wire pistol, it is supplied directly from the coil and cutting it into fragments is not necessary. Such a mechanism is distinguished by a number of advantages:

- ease of operation;

- reducing the timing of work to a minimum;

- good strength and reliability of docking compounds;

- economical wire consumption;

- reducing labor costs.

By cons can be attributed to the high cost of the instrument, as well as the need to teach working with it. In private construction, such a device is rarely used.

Reinforcement of belt foundation

The rod for reinforcement of the ribbon foundation is selected taking into account future loads on the design. Their diameter ranges from 6 to 32 mm, if we are talking about a small easy building, then this indicator can be about 12 mm. During the work, the following is used:

- metal bars;

- wire for mesh binding;

- bulgarian;

- plastic holders.

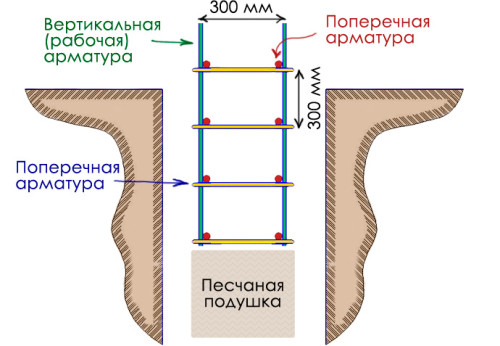

The grid of metal rods are associated in such a way that it fit inside the formwork, and at the same time there was some space at the walls, as a rule, it is about 5 cm. Among the methods of knitting the grid, the creation of a frame is considered directly inside the formwork. We describe the process sequentially:

- Initially, the rods are divided into fragments of the desired length. For example, if the height and width of the foundation are 80 and 60 cm, respectively, the rods are cut to a part of 70 and 50 cm long. For the reinforcement of the foundation, the rods are also needed to be placed along the entire length of the formwork, without getting 10 cm to its wall.

- Cutting the reinforcement, plastic holders on the bottom of the formwork and laid the longitudinal elements on them. In the ribbon foundation 4 such elements are laid down and as much on top. Side parts of the reinforcement are placed at a distance of 5 cm from the walls of the box.

- Longitudinal bars are binding in the corners in the crossbar places. After that, in a step of 25 cm, transverse 50-centimeter segments are attached to the longitudinal parts.

- After performing work along the entire length of the tape, the installation of vertical racks from the armature of 70 cm long is installed. The upper part of the mesh is performed by the same principle as the lower.

- The finished frame is poured with concrete.

Foundation reinforcement device

A columnar foundation is most often elevated under the fences or under light wooden buildings. The process of reinforcing such a design looks like this:

- After spending on the site all the necessary earthworks, find out the density of the soil and the depth of its freezing. Based on this data, the length of the columns is determined. Concrete pillows must be located below the ground freezing level. The parties of the poles in most cases are 25 cm at 25 cm, but sometimes the foundation is more massive. Such structures are placed in increments of 1.5-2 m.

- Having calculated the desired number of columns, the area is marked and digged in the ground to deepen the desired dimensions. The bottom of the pit is well trambed and rubbed a layer of 10 cm.

- For reinforcement of a column foundation, rods are used at 10-12 mm, which are divided into fragments of 35-45 cm long.

- The rods are binding in the form of a lattice with cells of 10-15 cm, after which the mesh is mounted in the pits by setting on a support from bricks.

- The next step is to fill the concrete layer about 10 cm.

- A week later, the formwork is performed and completely poured the column with concrete solution.

Reinforcement of slab foundation

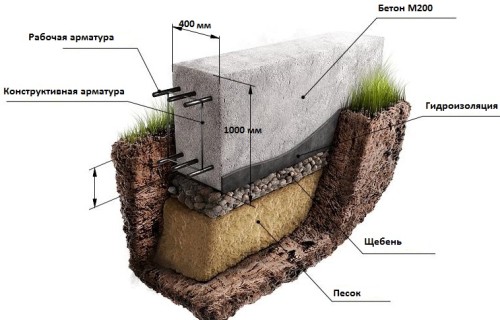

If the building is built on weak soils, when there is a significant risk of beating and mobility of the soil, the foundation of the slab type is erected. It is a monolithic concrete structure installed on top of a cushion and sand pillow.

Even if you use a reinforced mesh for the foundation purchased at a fairly low price, the cost of the whole design will be very significant, as you need a lot of building materials. But the bearing capacity of the slab foundation is very high, so that it is able to withstand heavy loads. Such a base also serves as a rough floor in the premises of the building.

The work process can be described sequentially:

- At the construction site, mark the markup where the foundation of the house will be located. Focusing on the markup, the top layer of the soil is removed to the desired depth.

- The bottom of the resulting pit is trambed and covered with a layer of sand and gravel.

- Then prepare a formwork, pre-providing for the location of the communications.

- The next step of the bottom of the recess is waterproof, after which they begin to reinforce the foundation. For these purposes, it takes the reinforcement with a diameter of 10-12 mm, cut it into fragments of a suitable length and fasten them in the form of a mesh. Cells of such a grid should be 10-15 cm.

- In those zones to which the bearing walls will be relying, perform additional strengthening of the rod.

The reinforcement of the slab basement grid is used for small buildings. For massive and heavy buildings, this method is not suitable.