Staplers of various types are widely used when carrying out repair or construction work, in the manufacture of furniture. The simplest and inexpensive tool is the mechanical stapler, and we will tell about choosing such a device in this article.

Content

Where construction staplers are used

The scope of use of construction staplers, including mechanical, rather wide:

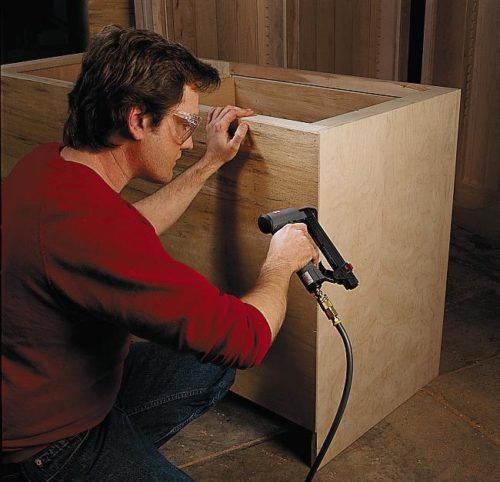

- Such adaptations are used in construction to attach materials to plywood, wooden, plastic bases.

- Staplers are simply indispensable in the production of furniture, where with their help carrying out the products of the fabrics.

- With the help of a construction stapler, you can sew plastic panels balcony or walls in the house.

- The tool is used when mounting insulating materials.

- They record electric or Internet cables, various canvases, drapery, canvas, posters, etc.

The stapler during operation can drive into brackets or small nails. In contrast to the hammer, the use of such a device gives better speed and performance.

Types of construction staplers

If we talk about building staplers in general, then you can allocate three main types:

- manual or mechanical;

- electric;

- pneumatic.

It is difficult to say which of these construction staplers is better because they all have their own advantages. If the electrical and pneumatic tools can boast the speed of tasks, then the mechanical is distinguished by the low price and ease of operation.

In the varieties of mechanical staplers, we will deal with more details. The principle of their work is simple, the power of the hands is responsible for bringing the tool into action. Pressing the special lever uses the spring, which, in turn, clings the bracket and shoots it in a certain place. Removing the finger from the lever, you return the spring back on the platoon.

There are several types of mechanical staplers:

- Ordinary - these are devices that, when pressed on the lever, shoot with brackets or nails.

- Cable is staplers intended for fixing electrical wires and cables.

- Hammer-like are tools that act on the principle of the hammer. Having hitting the surface, the stapler at the expense of inertia drivens a bracket. Such mechanisms are needed where the speed is more important, and not accuracy of work.

- Combined - devices combining the signs of the first two types of fixtures.

In addition to the above classification, staplers are also divided into household and professional. Professional are used for large volumes of work, and therefore increased requirements for their strength and deadlines. Unlike domestic, professional devices are unacceptable for fragile plastic parts. Such mechanisms must be maintained, that is, there must be a mark in their passports that the tool is serviced.

Professional devices must be easy and collected back, for which they are fastening with screws. And household staplers are often assembled with rivets and do not understand part.

Advantages and disadvantages of mechanical staplers

Speaking about the pluses of mechanical staplers, you can specify the following:

- low cost;

- low weight;

- ease of operation;

- no need to connect a power tool.

The disadvantages of mechanical devices include:

- the use of manual labor and muscular power to use the tool. If the scope of work is large, it is greatly tires;

- the functional features of the mechanical stapler do not allow it to work with high performance;

- relatively small fasteners that can insert into the stapler at a time. That is, the device will have to be able to charge.

How to choose a mechanical stapler

To choose the appropriate tool, you need to take into account some moments:

- The scope of the device and the types of fasteners with which you have to work. There are staplers that are refilled with brackets, nails or both. There are tools in which you can put several types of brackets.

- Power of the scoring mechanism. It is determined by the maximum length of the brackets that can score this stapler. In the characteristics of devices, the minimum and maximum length indicators are indicated, and the wider range, the more universal tool is considered.

- The width of the bracket should also be taken into account. Many devices work with fasteners of different widths, which is very convenient.

- It is desirable that the device body disassembled into parts. Then you will have the opportunity to clean and lubricate it from time to time.

- Take into account the ergonomics of the stapler, for example, the arrangement of the handle. What she is closer to the body, the more convenient will work with such a tool.

- Pay attention to the ability to adjust the construction stapler. If you work with soft materials, you will need a different power than when working with more solid bases.

- It happens that building staplers are equipped with a special function of repeated impact. This option is important when you have to drive fasteners into solid materials. When the bracket is not fully entered into the surface, the multiple impact function allows you to score it to the end.

- It happens at tools and another useful feature - the presence of a remote stop. With such a staple, you can drive fasteners at a certain distance.

The rules of operation of the construction stapler

- Before work, it is necessary to adjust the strength of the strike - it depends on the material with which you have to deal with. Using a screw controller, you can determine the power of the sprope on the bracket. If you work with soft wood, for example, pine, then this force should be minimal. But when driving fasteners in chipboard, laminate, oak or beech, the blow strength should be much more powerful.

- Configuring the power of the blow, do not use the stapler immediately on the working surface. At first, make several trial attempts on an unnecessary piece of material, for example, on trimming, which remained from the workpiece. So you will see whether to adjust the tool still or can be started.

- If the device does not have a retainer regulating the distance between the fasteners, take the place for the bracket with a pencil. So the result of your work will look careful. So that the material is not shifted, and you made shots aiming accurately, hold the workpiece with your hands.

- Follow the presence of a bracket in the stapler store. Many models for such a goal are equipped with a special transparent window. Seeing that the fasteners are suitable for the end, insert a new batch of brackets into the store, so as not to do idle shots. Slashes are taken to insert the outer sharp - do it that way so that the fasteners are not stuck in the stapler, and it has not failed.

- When working with any tool, including a construction stapler, you need to follow safety. For example, in the case of a bobbinist, the handle must be put on the fuse when the device is not used. By chance by clicking on the stapler, you can shoot the bracket into yourself or in someone nearby.

- It is necessary to care for the instrument too from time to time. If the stapler is disassembled, then it should be cleaned and lubricated. If you observe these simple rules, and also take into account all the features of your construction stapler work, you can avoid repair or breakage in the future.