When it comes to the erection of enclosing structures, such requirements as reliability, availability and aesthetics are always installed when choosing. All these properties have fences made of metal stakenik, which can be seen on the selected photos. Therefore, it is important to know the characteristics and rules for the construction of such a fence.

Content

Characteristics of metallic fence

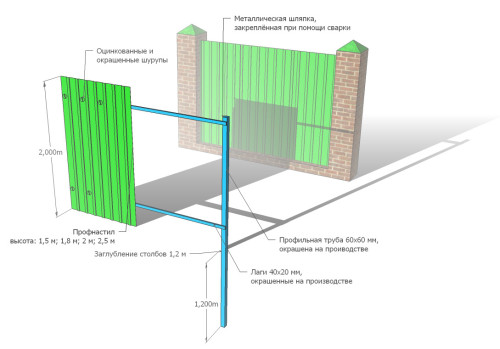

Directly design consists of a carrier and enclosing part. As a support can be pipes or pillars. The photo there are options from bricks, wooden or metal products. The most common option is profiled pipes of small diameter, they are inexpensive and durable.

Between them install metal stakenik - this is a profile made of galvanized. To protect the material and the decorative effect, it is covered with a layer of polymer paint. Sections are connected to the supporting elements with carrying jumpers from the profiled pipe.

In production, only high-quality components are used, steel has a thickness of 0.5 mm. And the coating is carried out on modern equipment according to special technology. This contributes to a long service life, manufacturers give a warranty period for a profile of 30 years, on the coating - 10 years.

The range of profile may differ not only by choosing a color, but also a height. There is a standard series, with manufactured characteristics:

- 1.5 m;

- 1.8 m;

- 2.0 m;

- 2.2 m.

In small production, you can always make an individual order, then the equipment is rebuilt on the desired product size. Many land owners when buying a stakenice choose products of several colors. When combining contrasting shades, a very spectacular fence made of metallic stakenice is obtained.

The advantages and features of the stakenik

This type of fence is distinguished by many advantages, among which you can allocate:

- strength, profile due to the presence of fractures in the structure is characterized by fractures;

- reliability that is achieved by fixing elements with rivets or screws;

- protective properties provided by the height of the erected design, through a two-meter fence, it is difficult to penetrate the attacker;

- durability of operation, for many years, the design does not require special care;

- low price and numerous color solutions.

Required tools and materials

To install a fence from a metal stakenik, the following tool will be required:

- bur, shovel for land work during the installation of supports;

- the welding machine used for fixing the transverse lag. Further, staketins are mounted on them;

- a screwdriver contributing to the rapid installation of elements.

Also used auxiliary tool that is present at each home master. For example: hammer, screwdriver, level, roulette.

It is important to prepare the following materials in advance before the process:

- profiled pipe with a cross section of 60x60 mm. The product with such parameters will exceed the weight of the future design;

- profiled tube 20x40 mm, which will serve as longitudinal lags;

- metal staketins;

- self-tapping screws for fastening stakes to frame.

Erecting fence

Directly installing the fence from the stakenik begins with the arrangement of the frame. To do this, determine the level of soil freezing and dig holes on this depth. Usually you have to make holes 1-1.5 m. To do this, use the boring and shovel. As a result, the distance between the supports should be 2-2.5 m, then the design is sustainable. For reliability under the corner supports, the pits are deeper, because the maximum load is transmitted.

In each dug hole, the pit is falling asleep on the bottom of rubble, sand, seal layers. Pick the pole height in advance, after installation, they must be higher than a 150 mm stakeholder. Then they put supports and poured with a concrete mixture. It should be borne in mind that the angular elements are first mounted, the remaining pillars are installed on the lighthouses.

The installation of the metal stake can be carried out in two ways:

- pivotal installation, then the manufacture of the frame continues the fastening of the longitudinal lag. For this, the cord is stretched between supports, adjust it in terms of level. For such a reference, profile pipes are welded throughout the perimeter. Horizontal lags can also be fixed with a special fastening in the form of a crab. Welding seds from above are ground, paint design - frame ready. It will remain to select the distance between the elements, it usually is 2-4 cm, with a chess location of 6-10 cm. And screw the metal sheets, it is important to correctly set the first element. Further periodically check the position of the stake in the level;

- with modular technology, the enclosing portion is made in advance. Separate sections in finished form are fixed between supports. It is possible to simplify the process using a template on which long bolts are used for mounting the stakenice. Then they will serve as limiters, and new sections will not be difficult.

Perform work will help the drawing made in advance. According to the draft design, it is much easier to navigate on the site and calculate the required amount of materials. Only after careful preparation, the process will pass without delays and nuances. To help you can view the thematic video: