Warm air always rises up. For this reason, in the cold time, a significant amount of heat from a residential building is treated through the attic (losses can reach 15-20%). To prevent heat loss, the insulation device of the attic ceiling is carried out.

Content

What does high-quality thermal insulation implies

When conducting thermal insulation works, the main point that enhances increased attention is adjusting the movement of steam. When admitting heated air flows, the maximum number of steam will be under the most ceiling.

Based on this, vaporizolation and insulation of wooden attic floors are carried out. The main requirement is that the waterproofing material should be placed on the part of cold air, and a vaporizolytor - from the side of warm.

Ultimately, such problems should be solved:

- preventing the wetting of thermal insulation material;

- resistance to condensate loss on the ceiling surface;

- lack of process of rotting;

- preventing the occurrence of icicles and land in the winter.

It is clear that in the presence of a monolithic attic overlap due to the high density of the concrete is an excellent barrier for reduced temperature. But in most cases the design consists of wooden beams. What makes thermal insulation work with a prerequisite for heat saving.

Varieties of insulation

To implement high-quality insulation of the attic overlap on wooden beams, it is necessary to correctly choose the material.

The most common materials for insulation attic are:

- mineral wool;

- styrofoam;

- extruded polystyrene foam (PESEROPLEX);

- polyurethane foam;

- bulk materials (ceramzite, sawdust).

Mineral wool

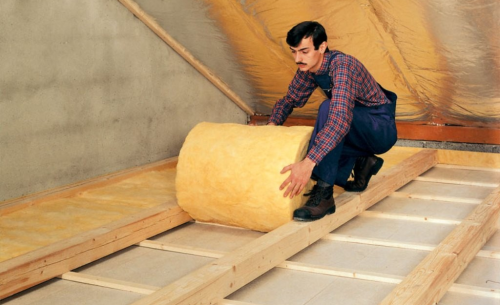

This material for insulation of the attic ceiling is sold in rolls and plates. Their difference is the scope of application. Mineral wool in rolls is laid on the floor of the attic, and the plates are stacked between the beams.

The main characteristics of the mineral wool insulation:

- low thermal conductivity coefficient;

- environmental friendliness;

- resistance to aggressive chemical environment;

- excellent fire safety;

- magnificent soundproofing properties;

- prolonged operational period;

- affordable price.

Mineral wool is characterized by the simplicity of installation work. Especially when the insulation of the attic ceiling by plates is carried out. Yes, and you do not need to acquire special equipment.

Polyfoam and penplex

Due to the low paramount indicator, the foam is superbly suitable for the ceiling thermal insulation on the top floor. The popularity of the material is explained by the fact that it has a small price.

In addition to good thermal insulation properties and attractive cost, foam is characterized by:

- resistant to the appearance of fungus and mold;

- slight weight;

- simplicity of installation;

- low water absorption.

Lack of insulation - low strength. When exposed to low temperature and high humidity, it will crumble. Yes, and fire safety leaves much to be desired.

Penoplex can be confused with foam. Both material possess the same characteristics and are mounted in a similar way. The essential differences between foam plastic - good fire resistance and a more dense structure, which is achieved through thermal processing of the material. This makes the insulation resistant to deformation processes.

Polyurene Foenethane

This material is a universal composition. With it, it is possible to carry out an insulation of reinforced concrete attic overlap. Especially indispensable polyurethane foam, when it is necessary to heat the surface where the pipes are passing.

The main characteristics of polyurethane foam:

- excellent waterproofing qualities;

- low thermal conductivity;

- good sound insulation;

- alkaline and acid resistance;

- mechanical strength;

- protection against rotting, fungi and mold;

- long service life (up to 50 years);

- lack of interest in rodents and insects.

With the help of polyurethane foam, a monolithic layer is created and all the slots are filled. The only nuance: sprayed material is too expensive when processing a large area.

Bulk materials

Availability and minimum costs are the main advantages of the insulation of the attic overlap of sawdust or clay. The thermal insulation qualities of these materials are significantly lower above. But with a sufficient layer thickness, reliable protection against cold air is ensured.

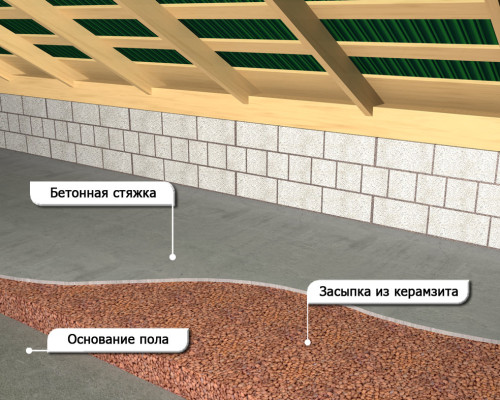

Ceramizite is distinguished by resistance to a wet environment, fire safety and environmental friendliness. It is more suitable for the insulation of wooden structures. After all, the sawdust in the original form is a flammable material. To use sawdust as a heater, cement, lime, boric acid and soap water are added to it.

Features of installation work

Mineral wool

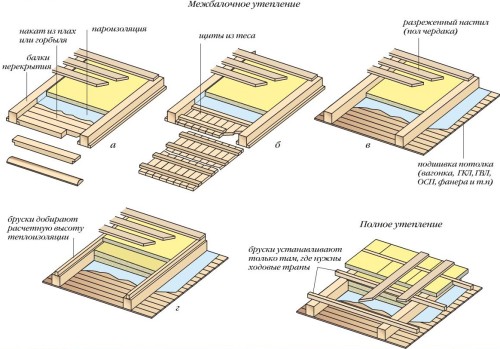

The insulation of the attic overlap on wooden beams of Minvata consists of such steps:

- laying a vapor barrier film with an adhesive of 10-12 cm (displays steam that comes from a warm room);

- film covers all protruding elements;

- in places in contact with the walls with walls, it is raised to a height, exceeding a 5 cm of the thickness of the plate, and sinking with scotch;

- the insulation is stacked (a sharp knife is used to cut the plates of the desired size);

- waterproofing material is laid;

- on top of the waterproofing, a draft floor (boards, chipboard, plywood) is made, which is the basis for the finish finish.

When laying mineral wool, avoid the appearance of gaps. It is also not allowed when the plates are very squeezed. In both cases, the quality of thermal insulation work will significantly decrease.

When working with mineral wool, follow the following recommendations:

- In the presence of protruding elements (for example, chimney), the thermal insulation material rises to the height of up to 0.5 m and is securely fixed.

- It is better to lay mineral wool with two subtle layers than one thick.

- When the height of the insulation exceeds the thickness of the beam, it should be lengthened by means of a good rail or a wooden bar.

- When using heat-insulating material with foil laying, plates are made with a foil side down.

Polyoplast (Penoplex)

For thermal insulation, the attic foam is necessary:

- align the surface (you can make a concrete tie);

- lay the plates between beams or jack;

- coat plates with waterproofing material;

- welcome boards or fane.

Shakes with beams should be sealed. For these purposes, assembly foam applies. If the attic does not plan movement, you can not lay the boards on top of the polyfoam.

Sawdust and ceramzit

To make a working solution from sawdust for thermal insulation of the attic ceiling, you will need:

- cement (1 hour);

- lime (1 h.);

- boric acid or other liquid with an antiseptic (7-10 hours);

- wood sawdust (10 hours);

- water (as needed).

Stages of work:

- the floor of a non-residential attic is poured with a mixture and smoothed;

- a cellular case of a bar is constructed;

- each cell is filled with a solution with sawdust;

- washed the draft floor.

The insulation of the attic ceramzite implies the following actions:

- mounted case of timber;

- the ceramzite of different fractions is poured and smoothed;

- the insulation is poured by concrete solution.

Useful advice

For high-quality thermal insulation, the attic experts recommend to adhere to a number of conditions. The main ones are:

- Creating a thermal insulating layer of optimal thickness. The minimum layer thickness is 15 cm (Polyoplex), 20 cm (mineral wool and foam), 40 cm (clay).

- Ensuring normal ventilating insulation. The ratio of the area of \u200b\u200bholes for ventilation to the sizes of the attic must be within 1: 500.

- It is better to use special membranes made from polyethylene or polypropylene as a vapor insulation material.

- Members more efficiently wrapping the sides of the lag and press the insulation, rather than cover the lags themselves. This is explained in that in the second case, steam-beam is disturbed.

- The presence of a ventilation gap between the flooring and the heat-insulating material in the amount of 3-4 cm. The holes for ventilation can be located both around the attic perimeter, so in the embedders in the floor.

- If necessary, the insulation can be additionally fixed using a dowel. It is done when the overlap has a base.

- For reliable fastening of waterproofing and vaporizolation to the crate or beams, a building stapler is used.

Video on the insulation of the attic overlap on wooden beams: