Brick is one of the most ancient building materials. Surprisingly, in the last hundred years, the characteristics of this product have practically not changed. Accordingly, the brick can be used in almost any construction. Even today, the brick is indispensable in some building processes.

Content

Of course, in the largest construction of bricks can be easily replaced by another building material. For example, it can be concrete slabs, or blocks. If you need to build a country house or just a small private facility, brick is the best option.

To date, numerous companies that produce building materials are offered a brick at a fairly attractive price. At the same time, you can be sure that the brick has all the necessary indicators, allowing to build a truly reliable structure.

In this material we will talk about exactly how you need to make brickwork. This process includes many subtleties, which is clearly worth mentioning.

Using a brick masonry solution

Of course, at the very beginning you need to take care of the appropriate quality of the cement mortar used to masonry bricks. Often in construction uses the most common cement-sandy solution. If we talk about the ratio of components (cement and sand), then most often it is 1 to 4-6, respectively. Often it is necessary to make the cement mortar become a little plastic. Due to the "dry" consistency, material for masonry may not be suitable for the building process. Accordingly, one part of clay or lime can be added to improve the plasticity. It is always necessary to remember that in the masonry brick, the cement-sandy solution is experiencing a load only on compression and offset.

Too liquid solution is recommended only in cases where we are dealing with full brick. Unfortunately, some problems may arise with hollow bricks. In particular, we are talking about the fact that the mixture can simply fall in the slot of the material, which is unacceptable. With this scenario, the brick is deprived of a substantial part of thermal insulation properties.

Most often, the preparation of the solution occurs by dry mixing of cement and sand, and then water is added. At the same time, it should be borne in mind that the cement-sandy solution makes sense to prepare only in small volumes. Often these volumes do not exceed 50 liters. If it is cooked more, then the whole solution can not be used to use, then we are faced with financial losses, since in time the unused solution comes into disrepair. In large volumes, cement mortar is prepared if we have several workers, which in a short period of time use it.

Tools used in the masonry process

Surely the most basic tool during brick masonry is Kelma. This device will make the most conveniently applied to the masonry rows. Moreover, Kelma will allow you to clean the excess solution, which is extruded when the brick fit. The back side of the handle can be adjusted to the brick itself. Accordingly, it is a multifunctional tool without which it will not do.

The second most important tool is Korkie. This device is an analogue of the hammer, but with a sharpened brought. This tool is necessary if there is a need for bricks, or it is necessary to simply split into a certain number of parts. In modern construction, it is often possible to detect a substitute for the blades - a grinder with cutting discs. Of course, Bulgarian will allow working quite quickly and as much as possible. In small construction, where there are no similar devices, you can safely use the dyfroke.

When laying bricks, it is also not to do without a construction level. With it, it is necessary to check the quality of the masonry of each brick row. Any deviations are unacceptable, as we are talking about the stability and durability of the structure. Together with the construction level, a plumbing is used, which will also make sure high quality of masonry.

In addition, the carpenter coal will not interfere. With it, it will be possible to check all the angles of the building structure.

Among the other necessary tools:

- master OK;

- roulette;

- cord;

- shovel;

- buckets;

- capacity for mixing the solution.

Common problems during brickwork

Separately, I would like to mention the basic problems faced by builders when creating brickwork.

Most often we are talking about the fact that most difficulties arise in the process of ensuring the geometric accuracy of masonry. Again, we are talking about the use of a construction level, with which you can quickly detect any deviations. Accordingly, if everything is done correctly, then ultimately we get straight vertical angles. Another problem concerns the creation of a brick series at the same level. Quite often, even small deviations can be rushed into the eyes, and also significantly affect the operational characteristics of the structure. If at least minimal deviations found, it is necessary to get rid of it during the masonry process, as then it will not be possible to correct the situation.

As already mentioned, in the process of laying bricks you need to actively use Kelmma. Each brick needs to be preserved, paying particular attention to cement mortar, which should be evenly located on the surface. It is necessary to fill with a solution of any voids present in the masonry. External masonry design is also a very important aspect. Cement, which is extruded between bricks, needs to be distributed over the entire surface. The seams also need to fill with cement mortar and make them monotonous.

If a laying of hollow bricks occurs, the holes should not go out. With this scenario, the brick will not be able to maintain heat, and therefore, we have spent money in vain. Moreover, water can fall in emptiness, which negatively affects the strength of the structure.

Brick Masonry Dressing Types

Before starting construction, the main types of brickwork should be explored. Most often in construction, three types of dressings are used, but it all depends directly from the specifics of the built structures:

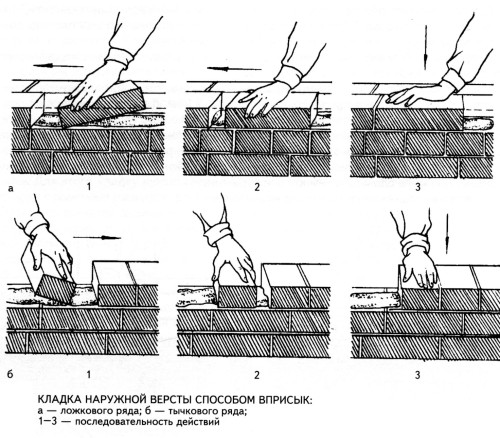

- Publishing bandage. This type of masonry is based on a number of bricks, which are placed to the surface of the wall so-called spoons (long faces). It is this type of dressing most often occurs in the construction process.

- Chain bandage. In this case, we have a masonry in which the tiley (short edges) alternate and spoonful brick rows. That is, bricks are placed and long edges, and short. Often there is the simplest alternation.

- Cross bandage. This type of masonry has a sufficiently unusual principle. Here the tiley rows alternate with spoonful. At the same time, it is necessary to keep in mind that the verticals of the seams in spoonful ranks coincide every three rows.

Step-by-step brickwork process

As you know, the process of masonry brick is quite simple. Accordingly, even newcomers will be able to cope with him, who have not previously had the construction of business. However, as already mentioned, in this matter it is necessary to show maximum attentiveness and responsibility, because even the most inconspicuous error can turn into a serious problem. Gradually, even small cracks in masonry can significantly affect the integrity of the structure.

As for the main stages of masonry, then they are as follows:

- Extraction of cement-sandy solution for masonry. In this process, the most common shovel is useful. It should also be borne in mind that here you can immediately use large volumes of the solution, as any flaws can be quickly removed. Immediately after the calculation of the cement, it is necessary to apply Kelma. We will spend this tool.

- Laying brick. To this stage, you need to start only after we conducted high-quality markup. Accordingly, the brick should be placed clearly within the markup boundaries. Most often to verify the correct location of the brick, the coincidence of the created markup with the upper brick edge is controlled.

- The process of placing bricks. After the brick is installed on the required place, you need to take a small hammer (preferably a Cyanka) and knock on top. This is done until the brick edge will coincide with the installed lacing. If everything is done correctly, then we get seams of the same sizes. In the same way, each new row of brick is stacked.

- Removal of excess solutions. Obviously, the construction process is often quite slightly. When the solution is raised and laying the brick, the cement mixture is simply over the limits of the masonry and can remain directly on the front of the material. In this case, it is necessary to use Celma again. With this tool, it is necessary to remove all excess solutions. Most often, the extra volumes of cement-sandy solutions are stacked between the ends of the brick.

As mentioned in order to simplify the building process, it is necessary to add red clay into the solution or lime. The mixture will be much plastic.

For marking, newcomers often use chalk or wax pencil. This will make it possible to make a brick laying, as well as forget about the possible errors of the location of the building material.

Other features of construction work

Do not forget that much can depend on the brick itself, namely from its dimensions, as well as properties. As we said, a hollow brick can be used during the masonry process, which has the properties of thermal insulation. As for the decorative brick, the process of its masonry is approximately the same as described above, but still there is a need to carry out a building process with particular care. The thing is that the decorative surface should not have any visible flaws, and even more so it is impossible to allow cement to remain on the surface of the brick.

In addition, in some cases, the use of brick is not appropriate. The fact is that everything depends directly from the scale of construction. If you need to build thick walls, then on the basis of a brickwork, the process can delay on a huge period of time. With this scenario, it may take a lot of working hands, or simply replace brick on concrete slabs. They are easy to install. In addition, it will significantly save time, which is in construction for gold weight. On the other hand, we should not forget that high-quality brickwork provides sufficiently good thermal insulation.

Returning to the tools It should be noted that many classic devices can easily be replaced with more modern. We are talking about advanced levels, allowing more high-quality masonry, as well as about many other devices. Cement mortar can be kneaded in the most conventional metal container. The main thing is to make it so that the masonry process was really convenient. In the conditions when the laying of the brick occurs in sufficiently modest conditions (construction of a small house with a limited number of workers), it is necessary to ensure that the prepared mixture is grabbed for construction. If we have a major building, then it will not work without a small concrete mixer. Moreover, this device will allow not to determine the mixtures for a considerable amount of time, which is important. As we have said, it should not prepare a mixture with a margin, since the cement will dry quickly and becomes unsuitable for use.