In private construction, much more often than the other varieties is used with a ribbon foundation. With all the seeming simplicity of the process of its design, knowledge is certainly required, certain skills of working with materials and accurate observance of the rules of technology during installation at each stage. Only in this case the foundation will be really safe and durable base for the house.

Content

- Varieties of the foundation of the ribbon type

- Opportion of the base of the house

- What instruments will be required to build a foundation?

- When is it better to install the foundation?

- Preparation of the site

- Selecting a waterproofing method

- Registration of pillows

- How to create a formwork?

- Reinforcement of foundation

- Where to pave engineering communications?

- Why do you need ventilation in a tape foundation?

- How to pour a ribbon foundation?

- Cutton concrete

- Video

- How to mount the national foundation?

- Conclusion

Varieties of the foundation of the ribbon type

Initially, to decide how to make a ribbon foundation, determine the type of suitable design:

Take into account the project of the building, the conditions of the construction site and the economic side, more profitable in your case.

Important! The process of construction of the foundation of the tape premium type is much easier, requires less effort. In addition, even minor settlement deviations during installation are considered the norm. For the design of the monolithic design, a strict decorated formulation of all solutions is required, the maximum accurate preview of all elements so that they are guaranteed to withstand the planned load for a long period.

Fundament device

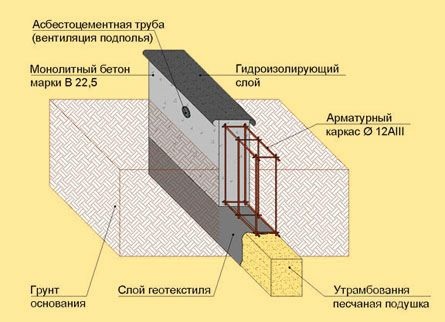

Learn carefully the principle of the foundation. Consider the location of its main components.

To obtain the right design, initially carefully read the plans of similar projects. Make your ribbon foundation schema.

Opportion of the base of the house

One of the most important stages of preparatory work is the calculation of the tape fundament. Determine all the parameters and the number of necessary materials using the appropriate mathematical formulas.

Perform calculations manually if you are familiar with such a job. But consider in this case the process will take some time.

Important! Use the necessary formulas to determine the soil type, the depth of groundwater and the freezing of the Earth on your site.

Speakeling the entire process will help the online calculation service, which today provides different construction companies. In order to make the right ribbon foundation - use it. Go to the site with such an application of one of the companies and enter data of known sizes. The program of automatic counting performed by all the design rules immediately emits a ready-made result.

What instruments will be required to build a foundation?

Prepare everything you need, focusing on this list:

- Shovel

- Trench man

- Level

- Hammer

- Screwdriver

- Drill

- Master OK

- Capacity for the preparation of mixtures

- Pipes from Asbestocerta

- Cord, fishing line, wire or rope marking

- Nails or self-tapping screws

- Concrete dry mix

- Wooden boards for formwork Pillows (short)

- Wooden boards for larger length for main formwork backup

- Waterproofing material

- Sheets of plywood or chipboard for formwork

- Crushed

- Sand

- Wire for reinforcement

- Armature of the desired diameter

- Concrete mixer

- Vibrotrambovka

- Waterproof film.

When is it better to install the foundation?

Plan all work on the warm and dry season in advance. Furzling or spacious soil is not suitable for mounting. This will cause inconvenience in the process of digging the trench, significantly slowing down all the work, but more importantly, will lead to shrinkage. The result will be the appearance of cracks, cropping the base and walls of the building.

Important! Be sure to learn a few days after the rains so that the missile is not only the top layer of the soil, but also the soil on the intended depth of the foundation.

Preparation of the site

Start decoring a tape foundation for the house with soil preparation. Stick in the following sequence:

- Measure the location of the corners on the site.

- Wake the rear of the reinforcement.

- Tension cord between them.

- Check the accuracy of the degree corner level.

Important! This markup will become an external outline outline of the future wall.

- By the same principle, perform the internal markup of the contour by increasing deep into 0.4-0.5 m.

- Determine the level of the angle on the plot below the total.

- From it, we swear the trench of the desired size.

Important! The edges of the pit forming the future wall must be equal to the fill of the ribbon foundation turns out to be accurate and neat.

- Check the depth as the digging of the level.

Selecting a waterproofing method

Special attention is paid to the selection of the correct method of waterproofing, since throughout the entire time of the foundation, it will constantly have a destructive influence of moisture and from groundwater, and from thale.

Decide with a suitable method of protection against moisture in the design process. Take into account technology, the right time to mount the material and the cost of all works.

The most demanded options in the current construction:

- Fooling mastic. The cheapest method used after filling and drying the concrete mix. Such a protective layer is least durable, quite suitable for household utility buildings.

- Laying a rubberoid or such rolled material. Until recently, the most popular way. Provides greater strength, and according to the destruction of the foundation of the house goes much later. Perform the installation immediately before the fill (the first layer is placed on the bottom of the trench) and after the solution of the solution, the surface of the mastic and warming up the burner for greater clutch, if this technology preferences.

- Liquid rubber. Very simple method, but more expensive. Apply the solution using a roller on the finished form of the foundation.

- Spraying waterproofing mixture. The most expensive method is due to the value of the material and the need to have special spraying equipment. After the end of the surface treatment of the finished concrete base, do not forget to fix the resulting geotextile layer.

- Penetrating solution. The most rational solution that does not require superfluous labor. Add a substance into a concrete solution when it is prepared. In this way, we form a durable, completely moisture-repellent material for filling the foundation.

Registration of pillows

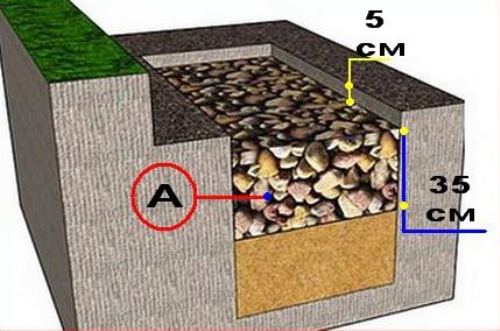

After the trench was pulled out, it's time to make her bottom. The occupation is not such a simple, as it may seem at first glance. Be sure to follow some rules of technology.

Important! Consider the uniformity of the load distribution from the foundation and the entire building, the degree of mitigation of the pressure of the structure on the ground depends on how correctly you will place the pillow under them.

How to prepare the bottom of the trench?

For registration of the bottom of the dummy pit, use sand and crushed stone. Prefer the material of large fractions when choosing sand and fragments in the range of 20-40 mm when buying rubble.

Important! Take into account that it is impossible to simply catch the soil or add soil from the plot for an additional layer. In this case, the required support density will not be achieved and shrinkage will be very fast (even 1 mm distances affects), due to which the finished building can collapse.

Perform work, adhering to the following recommendations:

- Check the sand quality (clean and dryness).

- Satch through the sieve, if you found a lot of impurities.

- Put sand on the bottom of the trench.

- Cross.

- Water with water.

- Take the layer of the desired density with the help of vibrotram.

Important! The smoothness and density of the pillow affect the strength of the entire foundation. Therefore, prefer not to ancient methods, but new technologies and special equipment for racing, quite affordable for rent.

- Repeat the procedure until the height of the finished layer reaches 10-15 cm.

Important! Form the width of the base of the sand pillow throughout the edges by 15-20 cm more than the planned thickness of the future belt foundation.

- Put crushed stone.

- Carefully scatter and confuse using the technique.

- Form the layer, thick up to 15 cm.

Important! For some buildings such a pillow will be quite enough. To make the most durable, continue to work, decoring the concrete layer of the pillow.

How to make a concrete layer of pillows?

Instruction:

- Prepare fittings:

- for a working, installed along, a brand A-II, A-III, diameter - 10-12 mm fit

- Place the arm of the working reinforcement, based on the calculation of 3-4 rods per width of 0.8m.

- Mount the transverse rods, withsting a step of 20 cm.

- Subscribe a low wooden formwork if the edges of the trench are not very smooth.

- Prepare a concrete solution.

Important! For this purpose, the M-250 brand is quite enough, a higher concrete strength is used to fill the ribbon foundation itself with your own hands.

- Fill the solution, focusing on the thickness of the layer 3 cm.

Important! Pour the entire surface at a time. Continue work no later than 12 hours if the solution or time was not enough to prevent the drying of the mixture and ensure the monolith of the layer.

- Wait for drying during the day.

How to create a formwork?

Forming formwork is the construction of a template for the proper installation of a ribbon foundation. The main task is to create a proper geometric form.

Frame construction technology under the fill of concrete

Instruction:

- Prepare all sawn timber.

- Sharpen one end of the alleged vertical supports.

- Install them in the ground with intervals in 1m.

Important! Note that the upper border of the formwork should be higher than the alleged foundation height.

- Attach the sheets of plywood or the material selected for the formwork for shields.

- Drive nails or self-tapping screws from the inside of the trenches, the hats inside the design.

Important! Such a fastening principle will make it easier to dismantle the formwork after rejection of the base.

- Set the backup area to which inclined beams that support the walls of the formwork will be relying.

- Introduce oblique boards, supervised by one end in the formwork, the second is in the backup.

Important! Regularly check the level of compliance with the parameters and the evenness of the lines.

Reinforcement of foundation

Use iron and metal rods to perform this work.

Important! Not necessarily when buying choose a rod with an ideal surface. It is fully allowed to use rods with a small rust raid, but without internal corroding. This is one of the options for saving construction.

The diameter and length of the reinforcement are calculated for each individual project, given the type of soil, the future load. With these parameters, the optimal step for the formation of cells is correlated.

Important! The diameter of the reinforcement for the private construction of houses, garages and other buildings of small size, usually does not exceed 12 mm. The simplest form of the design is two rows of vertical rods along the formwork bonded by horizontal bars from above-down, step 10-25 cm.

Progress:

- Put the bottom of the broken brick.

- Form a layer height of 50 mm.

- Cross.

- Install the vertical rods in pairs, withsting the specified step.

- Mount the horizontal line pair, forming the sizes of the cells specified in the project.

- Connect the nodes with wire.

Important! Perform work in such a way that the concrete mix after the foundation is fully covered all the elements of the reinforcement.

Where to pave engineering communications?

All lines are located above the level of the foundation or so that they do not pass through its thickness. It is especially important that this rule is respected with regard to water supply and sewage.

Why do you need ventilation in a tape foundation?

Having vent holes (so-called air holes), you will greatly enhance the total base cushioning prevent further moisture stagnation and odors indoors rot basement and ground floor.

In order to properly make the ventilation, keep the following guidelines:

- Prepare asbestos pipe diameter 10-25 cm (depending on the design features and frequency arrangement of apertures along the perimeter), sand, wire.

- Place tube in a trench horizontally.

- Check the accuracy of the line level.

- Secure the wire.

- Fill sand inside the pipe to prevent ingress of concrete mix.

Important! All work on the installation of ventilation follow after (or during) the fittings installed.

How to pour a strip foundation?

Die Casting - the main phase of a monolithic foundation.

The sequence of operation:

- Prepare a solution.

- Properly arrange the process to fill the mixture in the liquid and not dried up, consistency.

- Fill the base.

- Create the required layer thickness.

- Pierce the solution several times a metal bar or a shovel as concrete pouring to prevent occurrence of air "pockets" inside.

- Give the desired density by using compactors.

- Smooth out with a trowel.

- Look at the attached video below concrete.

concrete curing

Concrete drying process also requires constant care and monitoring. His uneven or too fast drying will reduce the strength characteristics and fracture created by the stone.

Consider the following recommendations for the regulation of the process of hardening concrete foundation:

- Cover dampproof film after completion of the screed to prevent ingress of excess fluid which will slow down the drying process and make the solution more "skinny".

- Regularly, before complete drying, at high temperature air, watering water to prevent too rapid evaporation of the liquid and reduce the reliability of coupling components of the solution.

- Remove the formwork after full cure.

- Proceed with further work no earlier than a month.

Video

Look below the attached video to more clearly present the entire process of building monolithic continuous footing.

How to install the precast foundation?

The principle of forming a national foundation is much easier than creating a monolithic, but also requires compliance with the rules for the installation technology corresponding to the selected material.

For the construction of a national foundation most often use the following materials:

- brick

- natural and artificial stone with high indicators of moisture resistance

- foundation Blocks FBS, 0.9m long, 1.2m, 2.4m

- foundated plates FL 14.12 and 12.12.

Perform the laying immediately after the pillow design, if the walls of the trench are smooth, or, if you need to create a formwork, after installing it.

Important! Pay attention not only to the laying technology of the selected material, but also on the correctness of the preparation of the fastening solution. From this directly depends the strength of the foundation of the foundation.

Conclusion

The whole process of building a belt foundation is quite complex, starting with the preparatory calculations, ending with the expectation of the rejection of the concrete mix or clutch the laying of the base of the collection type. But despite this, all the work is under the power to arrange independently. The main thing is to enlist the support of the assistants, choose the right view of the foundation, calculate the proportions, gently and consistently perform all actions, adhering to the rules and instructions.