Under conditions of constant increase in energy prices, household owners have to resort to the implementation of additional thermal insulation works. As a heater, many use expanded polystyrene foam. About how to choose high-quality polystyrene foam, and now we are talking about.

Content

Types of polystyrene foam

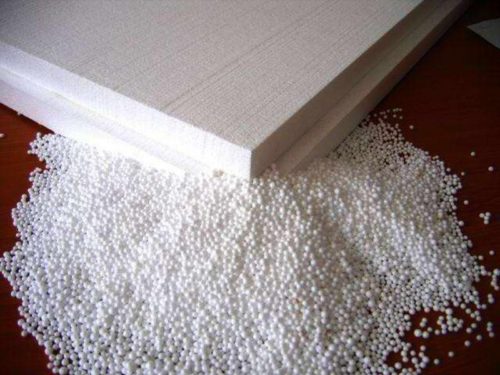

Polystyrene foam is a modern material, which achieves excellent thermal insulation of the building. It is used both when insulating walls of houses and carrying out the thermal insulation of the foundation (regardless of the level of groundwater).

But the sphere of using expanded polystyrene is not limited to this. Roofing, floor, plumbing pipes, transport pathways, window and doorways - all these items can be insulated with this material. Granulated expanded polystyrene can act as a filler for packaging or decorative element when interior decoration of rooms.

There are the following types of insulation:

- prestickable;

- extrusion;

- autoclave;

- press.

The most popular species of expanded polystyrene is the prestickable material. Moisture is removed from the granules using the drying process. After that, the material is foaming at 80-85ºС, drying and reheating. The resulting mixture is placed in a special form. When cooled, the material is independently compacted. The prestickable polystyrene foam is the most fragile, since the minimum amount of isopopan is applied to its manufacture (it is natural that it is the cheapest product).

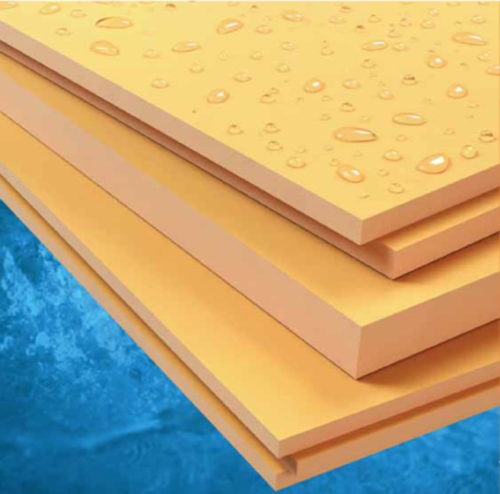

In the production of extrusion polystyrene is used special equipment - extruder. The material is obtained after processing the final polymer product. In most cases, extrusion expanded polystyrene acts as a raw material for the manufacture of packaging containers.

The main difference between autoclave polystyrene foam from extrusion material - the use of autoclave. This equipment is used when foaming and exposed to high temperature.

The most expensive product is the press material. The technology of manufacturing granulated polystyrene foam of this type occurs with the use of gas. This insulation has maximum strength.

Characteristics of polystyrene foam

The standard physicochemical properties of this thermal insulation material are:

- thermal conductivity - 0.03 W / MK;

- density - 33-36 kg / m³;

- parry permeability - 0.02 mg / m / h / pa;

- moisture absorption - 0.3% of the volume per day;

- compressive strength (with deformation phenomena in 10%) - 0.32 MPa;

- bending strength - 0.4-0.5 MPa;

- operational period - over 50 years.

The advantages of granular polystyrene foam (in addition to thermal insulation properties) include:

- a light weight;

- easy to transport and perform mounting work;

- efficiency;

- frost resistance;

- fire safety (due to the presence of flames);

- gorgeous soundproofing qualities;

- resistance to the appearance of fungus and mold.

Excellent thermal insulation properties of material are achieved due to air, which is inside the granules.

As for the ecology of granular polystyrene foam, it is worth noting the following. The material remains environmentally as long as high temperature does not affect it. At elevated temperature and in the process of burning, the insulation begins to oxidize. As a result of this phenomenon, harmful substances are released.

Criteria for the choice of polystyrene foam

Purchase of expanded polystyrene should contribute to the maximum exploitation of the thermal insulation coating.

The incorrect definition of thickness is a major error that can lead to a decrease in the service life of the material. Too thin insulation will be the cause of significant heat loss at home. Features and structure of polystyrene foams do not allow too thick material. As a result of temperature drops, such a insulation cracks or finishes "waves", through which cold air will come from the street.

When acquiring a insulation, first draw attention to its marking. For the facade thermal insulation works, PSB-C-40 polystyrene is suitable, which relates to self-refining products.

The number "40" indicates the density of the material, which is 40 kg / 1 m³. But not always implemented polystyrene foam PSB-C-40 has such a density. To make sure that the insulation is excellent, it is necessary to carefully examine it.

For this, a small piece of product is littered. The formation of an uneven edge with small round balls as a result of the fracture of expanded polystyrene testifies to the low quality of the material. The presence of the right polyhedra at the place of fault will be about the good quality quality of the product, through which the fault line will be.

When we choose the proper polystyrene foam, pay attention to four basic characteristics:

- material structure;

- compressive strength;

- water absorption;

- heat insulation properties.

The structure of the insulation must be homogeneous and finely. When the cells are clearly visible or the structure of the material is distinguished by high porosity, the polystyrene foam refers to products not the highest quality.

Compressive strength is checked by pressing the insulation. If the polystyrene foam "publishes" a crackling, then such a material (with thin walls and large cells) is unsuitable for the qualitative implementation of thermal insulation work. High-quality insulation can withstand a load of up to 60 tons / m².

The level of water absorption of expanded polystyrene can also be checked in a practical way. For comparison from two types of insulation, two pieces are cut off and on the day are placed in water. After 24 hours, the samples are laid out on the napkin. After pressing the low-quality material will be extruded more water.

The thermal insulation properties indicates the thermal conductivity of the material. This indicator is determined in laboratory conditions with special equipment. Maximum thermal insulation qualities are achieved only if the technology is met. In compulsory, polystyrene is covered by the effects of sunlight. To do this, use the cement-based plaster mortar.

The best producers of polystyrene foam are European Nova Chemicals, Polimeri Europa and Basf. Among Russian firms, Tekhnonikol and Penopelex products should be allocated.

Video about the choice of polystyrene foam in granules: