There are many options for sex coatings: linoleum, magnesia, polymeric. But concrete always performs as the basis. For alignment of the concrete surface, specially designed thicker cars are used. Simply put "helicopters". However, the selection of a cruise machine for a screed is complicated by the scope of application of individual models. Read in detail with the criteria of choice.

Content

engine's type

The models presented in the market are equipped mainly by motors operating on:

- gasoline fuel;

- electric charges.

Moreover, each of the grouting machines on an electric charge or gasoline fuel has its advantages and objective minuses. Equipment on the electric motor is characterized by low power indicators, which significantly narrows the spectrum of activity. Meanwhile, such machines are used in closed rooms, where there is access to the power grid.

Apparatus on gasoline fuel can be operated exclusively in the open air, because without powerful ventilation in the premises, the launch of devices is categorically prohibited. The advantages of this solution are complete autonomy and impressive power. Consequently, significant areas can be treated with gasoline aggregates.

Number of work surfaces

Based on the total number of working coatings, the equipment is conditionally divided into two types:

- single-breeding throat machines;

- two-door throat machines.

The devices of the first type are used when processing coatings of a small area (500 m²). They are cheaper, easier and safer many. As for the two-engine, they are used in the processing of significant areas.

Scope of plastering and clutter cars:

- processing of concrete coating in order to reduce the degree of pesticity;

- grout dry mixtures in the process of applying, the so-called strengthening layer;

- concrete surface seal;

- obtaining a smooth matte surface;

- starting grains of large aggregate;

- elimination of insignificant recesses on the surface.

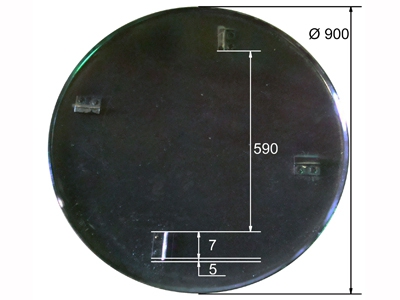

Diameter disk

This constructive element takes the most direct participation in the primary processing of concrete surfaces. In this regard, special attention should be paid to the selection of the disk diameter. When operating the unit on the electric motor, the discs with a diameter of up to 980 mm are most often used. Gasoline devices, especially groting machines of the company GROST, have a disk with a much larger diameter. Such equipment is perfectly coping with impressive areas.

Size blades

Based on the selection of the type of device, you will have to choose the blade of the appropriate size. Data parts can reach from 300 to 1200 mm diagonally. Moreover, the larger the built-in element, the greater efficiency will receive a rapid machine. The blades of the company "Kreter" and "Grost" are distinguished by the greatest quality of manufacture.

By choosing, it is necessary to keep in mind that the characteristics of all components of the device directly depend on the power capabilities. For example, if you want to purchase a burning unit for self-use, it is advisable to prefer electrical models with small size blades, disks, other elements. Such equipment will perfectly cope with minor tasks and will cost much cheaper than powerful gasoline devices.

Before buying equipment, determine the volume, complexity of work and natural budget. Experts for independent operation recommend Kreber or Allen Machines.

Construction of hardware device

1. Strip knot.

The working unit includes two main components for grouting - blades and discs. They constitute a single rapid equipment node and take part in the grinding of the concrete surface. All models presented in the market depending on the number of working surfaces can be with one or two rotors. We are leading in the supply of components for thicker machines such manufacturers as Enar, Allen, Kreber.

The operation of such devices depends entirely on the volume of the served surface and operating conditions. From the top of the node is protected by a strong lattice fence. This constructive means protects the operator from various injuries.

2. Controls.

All models of aligning devices have special handles on which levers for control are located. With the help of handles, the operator can effectively control the grinding process. In particular:

- adjust the speed of rotation;

- turn on and off the machines;

- customize the angle of inclination of the blades.

What is curious, the design of the handle is designed in such a way that the operator can easily fold the transfer device. Wacker, Grost, Kreber, such single co-core machines, ensure transportation even in cars with a small capacity of the luggage compartment.

3. Engine.

All work activities of such aggregates are based on the operation of the power plant. In turn, the engine together with the gearbox is associated with the working surfaces of the machine. As we have already said, the power plants of modern models operate on gasoline fuel and electric charge. Another type of fuel is distinguished, which functions for individual tattle cars "Allen", "Vakker". This is a diesel fuel, the devices on which is predominantly used in the open space with significant areas. Equipment on diesel fuel is a completely autonomous high-tech device with high power and performance.

The only minus of such devices is the lack of use in closed rooms with insufficient ventilation. To do this, there are models from the category with electric motors.

Final word

So how to choose a cloud car? To respond to this question, it is necessary to have a clear idea of \u200b\u200bthe volumes necessary for surface treatment, about the access of electricity, intensity of work, budget.

For example, there are self-propelled two-engine devices that are equipped with a convenient chair for the operator, as well as irrigation system. Such equipment is used on an industrial scale. Light pneumatic throat machines are adapted for small volumes. Naturally, in the first case, the cost of equipment will be much higher than the second option.

For a long period of work in the construction sector concluded that Kreber's thicker cars are a guarantee of a qualitative result. Never failed, nothing had to be repaired, only consumables changed.