Holidays at the cottage perfectly complement a good dinner, where their own cooked meat and fish smoked meats will be served. Such dishes according to merit will be appreciated in the family circle, they will fall to taste. To implement this, it is necessary to have a smokehouse at its disposal. It can also be made with your own hands. We offer to familiarize yourself with the information that will help implement the conceived.

Content

Species of smoke sets

The design of the smoke depends on the principle of its action. There are two ways to smoke products: cold and hot. With a "cold" method, meat and fish are exposed to a heated to 30 ° C for a week. To prepare a "hot" method, just a few hours at a higher temperature emanating from the coal - 90 ° -150 ° C.

Main options for smoke settings:

- for hot smoked;

- for cold smoking.

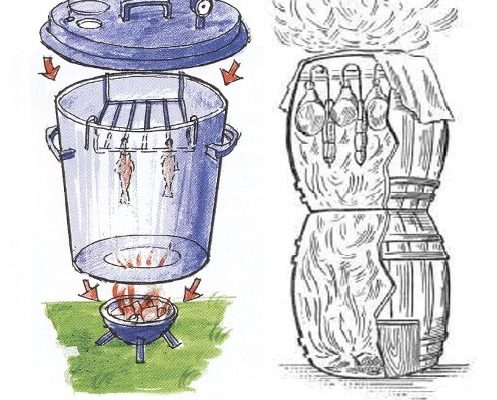

The settings of the first type settings are set. They are factory production and manufactured by a handicraft, from undergraduated materials. Consider from which you can make smoking with your own hands for hot smoking.

- Skolna from the barrel. With your own hands using a grinder to cut (for sealed barrels) or open the lid. Owls are poured on the bottom, and at the level of 10-20 cm above the middle set the grille cooked from 8 mm rods. Products are placed on the grille, and from above the barrel is covered with a canvas of burlap and a wooden lid. In this form, the barrel is installed on bricks located around the fire.

- The smokehouse from the galvanized steel bucket is manufactured similarly. The grille can weave from IV rods with a thickness of about 10 mm. For the exit of smoke in the upper part of the bucket, a hole with a diameter of 2-3 mm is drilled. The bucket hangs on the handle over the fire.

- Smokehouse from the old refrigerator or iron box. The refrigerator is released from plastic and rubber pads, turn over the back wall down and installed on bricks located by the fire. Opening the door, placed on the bottom metal baking sheet made of steel sheet. Chips poured on the tray. In the upper part, the corners are fixed - the shelves for reinforcing rods with hooks, on which meat loss or fish. The door is closed, and on top of the whole construction is covered by burlap.

- Skolnya from the tank. Suitable for this, a tank of stainless steel, on the bottom of which chopped. Products hang on hooks at the top. For dripping fat, the foil sheet is placed on top of the chips. The tank is covered with a dense cap with a small hole done in it for the exit of smoke.

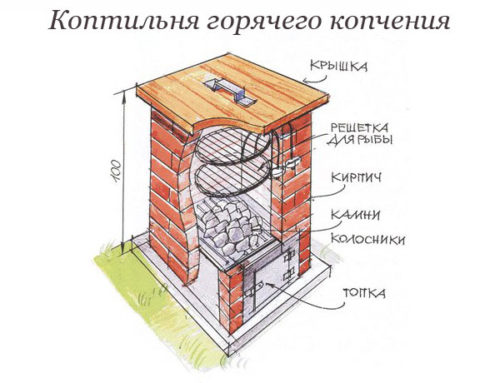

- From brick. On a concrete base, the walls of the constructions of the square section (0.5 × 0.5 m) are laid (0.5 × 0.5 m) and 1 m height. Furning doors are installed in the lower part, and inside - grate and above - grille for products. Close the smokehouse with a wooden lid.

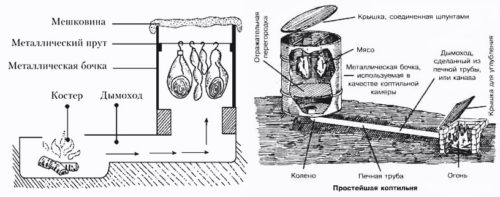

Smoking smoked smoking can also be made in different ways.

Smoke smoke in chimney

The algorithm for the manufacture and use of such a device is as follows (how to make a smokehouse from a tree with your own hands):

- From the board, the box is roamed with a size of about 0.5 × 0.5 m at the base and 1 m height. From the inside the box is frowning with iron. In the front of it, the door is satisfied.

- Inside the drawer (at the top), hooks are installed for hanging products.

- From the bottom side of the rear walls, a round hole is done, into which the sleeve is inserted from a metal pipe with a diameter of 100 mm.

- From the inside of the drawer, the pipe output is closed with a movable damper - to regulate the amount of smoke and disconnect the device from the chimney.

- At the top of the box, we arrange a similar hole with a sleeve and damper.

- In the brick wall of the chimney (in the attic) in places corresponding to the location of the sleepers, with the help of the crown, we do holes. We establish a smoke sleeve in the holes and seal the slit using an alabastra aqueous solution.

Note: During the smoking, the oven stove for a long time, but with a small amount of wood decodes of trees. Coniferous and maple should be deleted: such wood can give bitterness.

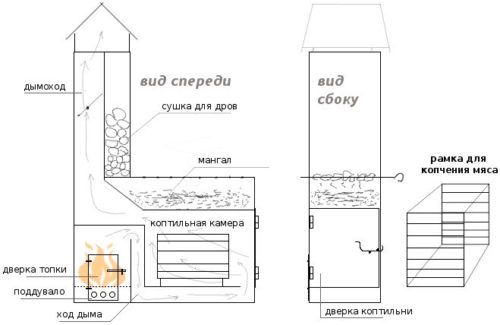

How to make a smokehouse from stone and brick do it yourself

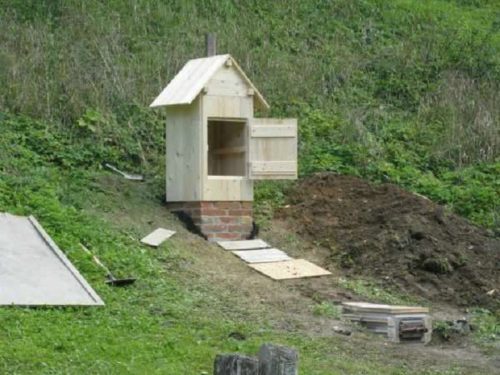

The main difference of the device for cold smoking from the smokehouse "hot" way is to remove the firewood burning focus from the camera with products. Smoke penetrates the chamber on a special chimney. This is necessary so that the process of burning firewood and coal damage has not affected the quality of products. The whole construction process of smokehouse from bricks can be divided into several stages.

- Choosing a place. To build a smoke should be so that the smell of smoke and smoked breaths penetrate the house and did not interfere with the neighbors.

- Choosing a design (with a stove, with a stove, etc.) and the preparation of the drawing. It is not necessary to design the device yourself: ready-made schemes with "coaches" can be found on the Internet.

- Preparation of materials. You will need bricks, furnace mortar, grate, firebox door, grille or rods with hooks, lid, streaming for smoke, formwork boards and fittings. From the tools it is necessary to have at its disposal a container for kneading the solution, culma, a spatula, level, hammer, shovel.

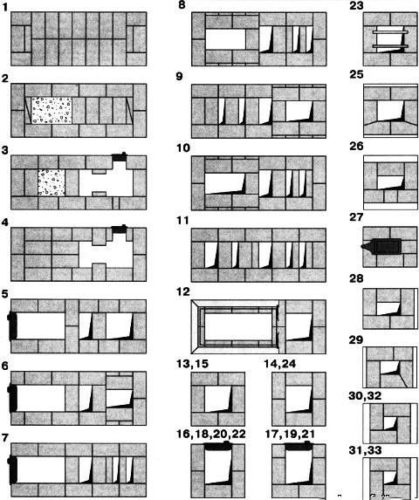

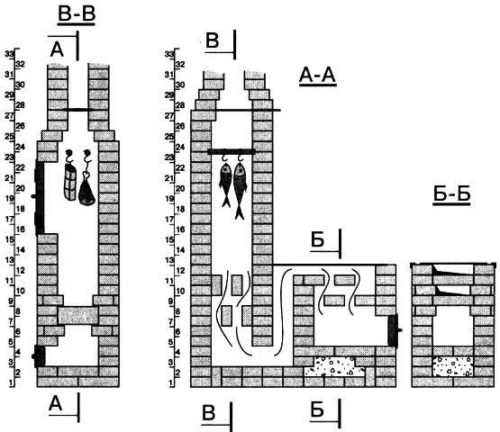

- Filling the foundation. At first, on the markup, you need to open a hole with a depth of about 50 cm, the bottom of which is rambling. A mixture of sand and rubble layer 250-300 mm, which should also be tamped to the bottom. The formwork is constructed, reinforcement in the form of a bunk mesh with a cell of 100 × 100 mm, concrete is poured. Such a base is constructed for firebox and for smoking chamber.

- After pouring the concrete (after three days), the formwork is dismantled and masonry work begins. In accordance with the "order" scheme, bricks or stones in terms of the level are laid on the dressing solution. At the same time, they should be pressed, boding the knob to the cells so that the solution completely filled the place under the brick. Surplus are watched with a spatula or trowel. During masonry, the quality of work is controlled by a plunder or level.

- For the device of the chimney from the furnace to the smoke chamber, a trench of 2 m long, a depth of 0.5 m. For the chimney, a canal of brick is laid out or a ceramic or metal pipe is used.

- The door is installed in the furnace and coopers, in the smoking chamber - grille or hooks on the rods of reinforcement.

- A vertical chimney is installed for the exit of smoke above the smoke.

After the construction is completed, the device must be checked in operation. Sawdres are poured for this and burn the furnace. Fish or meat is placed in smoking. Vertical chimney from above closes so that the smoke is filled with smoke. At that moment it is important to trace so that the smoke does not come out of the gaps (all detected tightness defects need to be corrected). With the thermometer, the temperature is observed: after the scale rises to 600 ° C, the chimney opens. After half an hour, you can check the quality of the finished products.

It is recommended to have a firebox and smokehouse at different levels, for which it is convenient to use the field relief features

What is a smoke generator

In order to make the smoking process easier and controlled, the smoke generator is used. The principle of operation of the device is based on the decline in sawdust heated by electrotane (spiral) and the discharge of a formed smoke in the smoke chamber. Products can be placed in the tank of a suitable form and a volume made of wood or metal.

Advantages of the smoke generator:

- uninterrupted injection of smoke in the smoking chamber;

- minimal chip consumption;

- process automation;

- the possibility of applying in an apartment.

IMPORTANT: You can not use for the device of the smoke chamber of plastic containers. It is unsafe for health and can cause a fire.

Pros and cons of smoking methods

Before deciding which device to build on its site should be studied all "for" and "against".

Advantages and disadvantages of smoking hot smoked

The benefits include the following.

- Preparation speed: a few hours after the start of heating, the product can already be eaten.

- The smokelessness of the portable smokehouse with a water shutter makes it possible to use it in the apartment. The shutter prevents the ignition of chips, thanks to which the process proceeds safely.

- Finished products are tastier than smoked "cold" way. Their color and the fragrance comes from them are more rich.

- Small dimensions of the device make it easy to clean the smokehouse after use. You can take it on a trip.

The disadvantage of hot smoked smoking is a relatively small shelf life of finished products: no more than three to four days in the refrigerator.

Advantages and Disadvantages of Cold Smoking

The main advantage of smokehouse for the "cold" way is that the products prepared in it can be stored for a long time. With the right ambol and appropriate conditions (in a dark, ventilated room) - at least six months. Disadvantages are as follows:

- for cooking requires a long time;

- the complexity of the design of the device;

- bulkness and high weight smokely, for some exceptions, it does not allow them to be considered mobile.

Skolna from gas cylinders do it yourself: design feature

Gas cylinders for propane are equipped with two or three cameras:

- fire breeding zone (firebox);

- hot smoked zone (horizontal chamber located slightly above the furnaces);

- cold smoked zone (vertical camera).

The principle of construction consists in separation of fireboxes and smoke cameras. Hot smoke immediately enters the hot smoking chamber, while the coals and ash remain in the furnace. In the cold smoking chamber smoke falls through the hot smoking chamber. Due to this smoke, it has time to cool down to the required temperature, which is controlled by an embedded thermometer.

Cottlen options from gas cylinders: without a cold smoked camera (left) and with a cold smoking camera (right)

Features of portable smoked smoked smoked type, created from gas cylinders - in the presence of a wheeled pair (see photo). This allows you to freely move the device within the area.

Your attention is a detailed instruction on how such a smokehouse is made with their own hands (video with explanations of the wizard).

How to choose chip and firewood for smoking

The right selection of chips and wood is important, as it has a direct impact on the taste quality of the finished product. To prevent an error at this stage, the councils of specialists should be adhered to.

- The best chips and sawdust for smoking is made from the wood of alder and juniper. Good quality smoke gives oak, birch, ash and fruit trees.

- It is impossible to use seppe of coniferous trees: the resins allocated by them give bitter meat and fish.

- To obtain a better aroma, use mixtures of chips and sawdust of various tree breeds.

- The chip must be released from the bark: it can also give bitter products.

- In order for fish or meat, you purchased a golden color should use for smoking the sawdust and chips made of mahogany. Oak and Olha give the product dark yellow color. Lipa, beech and most of the hardwood trees stain meat and fish golden yellow.

- Ships should be dry, with the exception of recipes requiring its moisturizing. The material is not suitable with signs of rotting and "sinushnosis" damaged by insects.

- The chip is recommended to add aromatic herbs, rosemary, almond shell, juniper branches. For fish it is better to use vintage branches.

How to harvest the raw materials for smoking

At home, the chip is prepared from chocks of suitable wood with a small ax and container with clean water. The sequence of actions is the following.

- Chock is freed from the bark.

- The wood is crushed with an ax. Fragments should be about 20 × 20 mm.

- We wash the chip in the water of 4 hours.

- Remove the chip from the water and decompose on the dishes in a dry room, where wood should dry to the state of the desired humidity (in the range of 50-65%).

The information described in the article will help make an independently smoking device, chips and please your loved ones and guests with a delicious dish. Bon Appetit!