In modern construction, several important trends can be separated separately, one of which is a significant simplification and acceleration of the construction of the building while maintaining the strength standard characteristics. It is impossible to better meet these requirements for these requirements - blocks based on porous concrete of high strength. One of the most popular varieties is aerated concrete, the methods of application of which are described in this article.

Content

Advantages and disadvantages of concrete blocks

Masonry walls made of aerated concrete is a pretty effective solution within the private and low-rise building. This material has a number of advantages which allow its continued relevance. Note some of the most important aspects.

advantages of aerated concrete

- High strength, which excludes breakage, crumbling and the loss of the attractiveness of the appearance after a certain period of operation.

- Long resistance period - up to 100 years, at the same time at least 30 years is a guarantee manufacturers.

- The rate of building a building due to major elements.

- Low thermal conductivity, which provides a good indicator of the preservation of heat in the room at any time of the year.

- Fire and frost resistance allows the use of aerated concrete for construction in any location conditions.

- High accuracy of geometry of piece elements, which is achieved through the use of string cutting and additional processing during production in autoclaves.

- Efficiency - thanks to the large size of blocks for construction, less consuming material, both the main and fastening, is required.

Important! Separately, we note such important dignity as the cost of masonry of walls from aerated concrete, which is much lower than the installation of other pieces due to the acceptable pricing policy of manufacturers. When compared with standard brick, the difference is up to 40%.

Cons Masonry walls from aerated concrete

- The presence of lime impurities reduces the hygiene of this material.

- Features of the structure contribute to the accumulation within moisture and its preservation, which can cause the freezing of the walls or the occurrence of mold.

How to choose the right blocks?

The thermal insulation characteristics of the building and its strength depends largely on the quality of the selected blocks. In order not to miss when buying and not choose a bad aerated concrete, follow the following recommendations:

- Take acquisition only in well-proven manufacturers.

- The optimal density of the material is the D500 indicator.

- When receiving blocks, be sure to check the quality of the geometric shape.

Important! When performing all these simple rules, the laying of walls from aerated concrete will be very fast and easy.

Instruments

To fulfill the entire amount of work without delays, get drunk in advance about the preparation of all necessary tools:

- special muscles for applying a solution;

- saw or hacksaw with carbide large teeth;

- manual or electric strokeshes;

- mixer blade;

- tanks for the preparation of the solution;

- cutting kit at right angles;

- coarse grater with metal teeth;

- the grater with a coarse skirt;

- building level;

- marking cord;

- rubber cizyanka;

- plane;

- armature with a diameter of 8-10 cm;

- narrow brush for removing dust from stroke.

What to choose a solution?

To perform masonry of walls from aerated concrete, the video instruction of which is suggested below, it is permissible to use two types of solutions:

- special adhesive for aerated concrete;

- the mixture based on cement and sand.

Important! The price of laying walls from aerated concrete depends largely on the type of the selected binder material.

Pros and cons of glue

Glue for aerated concrete is proposed by manufacturers mainly in the form of a dry construction mixture based on white cement. Standard preparation proportions look like this:

- 10 kg of dry mix;

- 21-23 liters of water.

Important! The thickness of the layer using a special adhesive is 1-3 mm.

Advantages:

- simplicity of cooking glue;

- the ideal smoothness of the surface of the walls after laying the material;

- cleaning seams of masonry;

- increased thermal insulation characteristics of the building, due to the smaller size of the seams;

- excellent adhesion indicators.

Minuses:

Advantages and disadvantages of cement mortar

The classic version of such a mixture is the following proportion:

- 4 pieces of dry sand shallow fraction;

- 1 part of high quality cement.

Important! The resulting density of the solution determines the required thickness of the layer of the mixture when aerated concrete blocks is connected. The standard indicator corresponds to 0.5 - 1 cm. In this case, the flow rate of the dry mixture is approximately 18 kg / m2. Depending on the timing of the construction and seasonality of work, it is permissible to use some of the additives-plasticizers to accelerate the setting or enhancement of frost-resistant solutions.

Pros:

- when using cement-sand mixture, the use of non-high quality elements for masonry walls is not very high, with possible deviations with respect to the definition of the shape geometry;

- all types of consumables for the preparation of a fastening composition during construction are always in stock.

Minuses:

- the preparation procedure is longer than long;

- a sufficiently large seam thickness causes a decrease in thermal insulation characteristics;

- the need for mandatory finishing of surfaces.

Laying of walls from aerated concrete - Rates

Before you finally decide to complete the construction of the walls at home with your own hands, check out the price list on such services of several companies. On average, the cost of installation is 1200-1600 rubles / m3.

Important! Given the fact that even when the 1-storey building is erected, the walls of the walls will be quite significant, the savings are obvious. Taking into account the fact that such a type of construction is characterized by a special simplicity - the only correct solution in the presence of free time is precisely personal participation in the process of wall structures.

Montaja technology

Before you begin the construction of the walls of your own home, create a monolithic type foundation with such parameters:

- at least 1.8 meters of depth;

- 0.4 meters width.

Important! These indicators are an optimal option for creating a house of 1 or 2 floors. After pouring the solution, apply waterproofing material to the surface. For this purpose, any type of reasonable value is suitable - from a regular rubberoid to more modern liquid rubber.

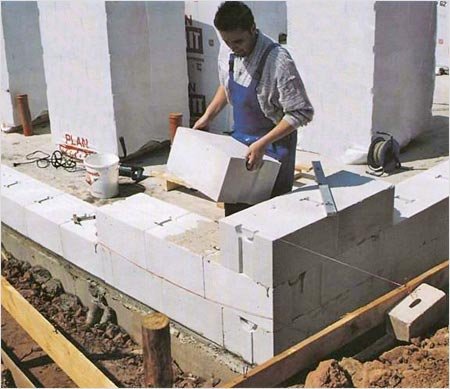

The most responsible moment is the creation of the first row. From how correctly you do this work, the subsequent speed of laying the rest of the material depends.

Installation of aerated concrete blocks. Perform as follows:

- Using the level, determine the highest angle.

- Prepare the cement-sandy solution in the ratio of 4: 1.

Important! The first row is always laid on this type of mixture, regardless of the selected main technology.

- Apply a layer of 10 mm.

- Moisten the bottom surface of the material.

Important! Such a procedure is necessary to preserve moisture in solution, and to exclude its transition to a gas-block due to its porous structure. Otherwise, cement mortar will lose its strength.

- Install the first block.

- Align its position by level.

- Install the aerated elements on all corners, focusing on the position of the first.

Important! Use for this purpose a tension cord and level.

- External spikes of angular details. Position outward so that it is easy to make it easier.

- Fill all intermediate rows between the corners.

Important! Convenience of mounting is provided by the presence of special grooves that make it possible to make a convenient capture of the part when it is moved.

- All vertical surfaces of the aerated concrete blocks are pre-treated with glue.

Important! In principle, the principle design of a spike-groove provides the ability to do without additional fastening material. But to increase the reliability of your own home, ignore the procedure for additional treatment with adhesive mortar is still not worth it. Browse the video example of masonry of the first row of gas blocks.

- The second and subsequent rows are placed by similar technology.

- Install the angular blocks.

- Check out the evenness of their level position.

- Apply the adhesive with a lamb.

Important! When using a cement mortar, the use of the usual workman will be more convenient. When laying on a special adhesive for aerated concrete, the best solution is that the bucket, which allows you to strike the quickly thickness of the desired thickness up to 2 meters long.

- The joints of the blocks twist on the principle of brickwork - alter with a distance of at least 8 cm between adjacent rows.

- Ginger all the protrusions grater.

- In the places of each window opening, drink the strokesis of the groove.

- Clean the removal from dust with a brush.

- Fill them with a solution.

- Set the reinforcement in each excavation in such a way that it comes out for the edge of the opening no less than 50 cm.

Important! Such a procedure is required to properly distribute the increased load on the side surfaces of the openings.

- All slots and holes, preserved after the end of the masonry, fill in a white repaired solution.

- Screw the walls from the outdoor and inner side.

Important! Compliance with this rule will help protect the walls of destruction when exposed to constant adverse factors. Browse the video instructions for the design of the second and all subsequent rows of aerated concrete.

Conclusion

Regardless of which method of fastening the gasoblocks, you preferred, be sure to follow all the meaningful uncomplicated rules in the process of building the walls of the house. In this case, you for a long time do not have to worry about the need for restoration work or doubt the strength and reliability of your housing.