Houses from the log house are becoming increasingly popular every year. They are warm, beautiful and very durable, so it is not surprising that more and more people prefer their typical brick or concrete structures. But in order for living in such a house it was really comfortable, it is necessary to approach the construction very carefully and know all the nuances of technology. One of these nuances is caulking. About what it is, and how to make a carp of a log cabin with your own hands and let's talk in today's article.

Content

Purpose of Konopkka

Wooden houses have a lot of advantages and advantages compared to brick, stone or concrete structures, not to mention frame buildings. It has been written about this. The most important of them is shrinkage and deformation of the wooden elements as a result of a drying. The slots are inevitably formed between the logs, which is quite natural, because the logs do not have perfectly smooth surfaces. And, though, the house can be built from the processed calibrated log, the occurrence of gaps still remains a problem. Through them inside the cold penetrates, so it is necessary to do everything possible to eliminate any lumen. For this and came up with a pantry.

The main cause of "depressurization" is the destruction of wood, and even the one that has passed pre-processing. Wood building materials have a certain percentage of moisture, which gradually evaporates. As a result, wooden structural elements change their volume and geometry, forming a gap. Having dealing with a log cabin, it is impossible to avoid the appearance of gaps, so the house needs to be caught. The process is to fill the lumens between the logs with thermal insulating material, thereby preventing the penetration of the cold inside. Work requires tremendous patience, accuracy and scrupulsiness, so many of the owners of the log cabins prefer to hire specialists. If you want to save, or you are interested in trying a pantry with your own hands, detailed instructions in this article will help to figure out.

The process of warming the harness, and the main tool that is used for this is also konopathic. In Starin, the Masters-Capatakers were valued by the weight of gold, and now such services are not suiced. By the way, today they use all the same technology in centuries, since it allows to ensure maximum thermal insulation.

So, for what you need a carp of a log house:

- elimination of cold bridges, insulation of the room;

- closeing of gaps in the corners, crowns, window and doorways;

- adjustment of house assembly defects;

- giving a cutter and completed formation cut.

The pantop is spent several times: the first - after shrinking at home (six months after the assembly), the second - before the finish finish. Next, the house is careated as needed.

Material for Konopkka

Close the slots between the logs can be different materials. In the old days it was used predominantly moss and wool. Today the selection of insulation is much more diverse, so it is possible to find an option for any needs and financial opportunities.

There is a list of requirements that must match the perfect material for the cutter of the cut:

- low thermal conductivity;

- environmental purity;

- immunity to rotting, damage to parasites, rodents, the formation of mold, etc.;

- moisture resistance;

- resistance to temperature differences;

- resistance to mechanical impacts;

- the material should not have a sharp smell;

- durability (service life at least 20 years without loss of operational characteristics).

Below we will list all the materials used for the cacopa, and looking at the list of requirements above, you can choose the best option.

Natural materials

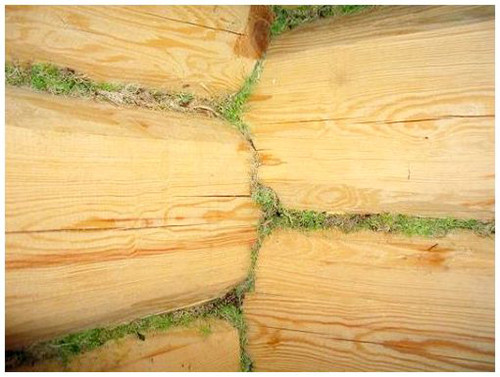

As we said, I used to use moss before, so there is no reason to not do the same today. Many specialists believe that it is Moss-Sfagnum that is the best tool for warming a church. Collect it in the outskirts of the swamps and score slots between the logs until the moss is still drying. In this paper, this material is very fatty and easy.

Useful advice: To check whether the slot is qualitatively the legitimate, it is seeded. If the tip comes tight, then the work is performed well.

The main advantage of moss, as well as other natural materials, is its absolute environmental purity. However, for the same reason, the main drawback arises - the moss is an ideal habitat of small insects, it can provoke the appearance of mold and fungi. In addition, Moss is not able to protect against moisture and has a small service life, so that the house will have to be caught quite often. Everything is clear that the cacopate of the cut of a moss only in the event that it is necessary to save or the process of sealing the slots very much like you.

But the moss is not the only environmentally friendly material used for the cacopa of the log cabins. Pacle is suitable for this purpose no worse. It is clogged into the cracks in its pure or pour from above cement or gypsum solution.

Jute and Jute fiber are similar to the pass, but not made of flax, but from cannabis. Konopka Srub Joutow was held in ancient times, and this method is relevant to this day. Jute Unlike MCH has better hygroscopic and high strength. Even with extremely high humidity, it will remain relatively dry and the maximum of 20% of moisture will absorb. For this reason, it is used for the cacopa of baths.

IMPORTANT: Jute felt is unsuitable for cacopa, because in its composition, in addition to hemp fiber, there is a flax. Linen fibers are very fragile, attract insects and can provoke the appearance of mold. Konopka cut of packles is extremely undesirable. Alternatively, it is possible to handle the cracks with antiseptic agents or poisons from insects, but then the ecology of the method is lost.

Linovatin is another natural environmentally friendly material that can sort with jute fiber. It is made of waste after flax processing. By and large, flanutin (from the words "Len" and "Wat") is a compressed linen dust. Such a structure makes the material quite tough and durable. The flanutin protects well from the cold, it can absorb and quickly evaporate moisture, preventing wood dropping. For sale, the flanutin enters the ribbons of various thickness, so it is convenient to work with it.

Synthetic materials

It would be strange if today we used only those materials that went from the ancestors. The modern industry is also capable of something and offers several effective means of rooting cutter. So, special smears are very popular, which are based on various substances: silicone, polyurethane, etc. The use of silicone sealant for cacopate is very doubtful, because for the wood it is completely natural to absorb and evaporate moisture, and Silicone will not allow her to evaporate. As a result, such walls will simply be rotten.

Polyurethane sealants for logs calmly solve the temperature differences, indifferent to the ultraviolet and do not interfere with the cut "breathe". However, in no case do not use polyurethane means in cylinders - they will quickly be destroyed under the influence of sunlight.

For sealing seams, you need to use the most elastic materials so that they can withstand regular timber movements. Some cramps can be made with your own hands using natural clay, cement and river sand as ingredients. However, this mixture will not be elastic and quickly cracks.

Useful advice: choosing material for cacopa, oriented on its consumption. This indicator depends on the density of the fit of the bars and the type of their compound.

The process of cacopa

To make a carp of a cut as correctly correctly from the first time, it should be strictly adhered to the work technology. It is impossible to proceed to it immediately after assembling the house - it is necessary to wait for his shrinkage in 5-7 months. Otherwise, you just spend wasted time, effort and money.

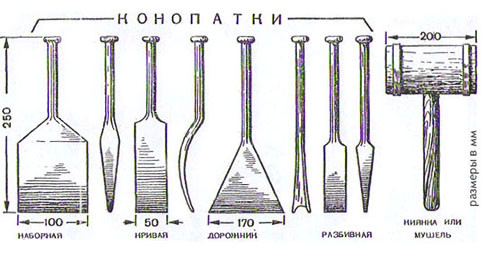

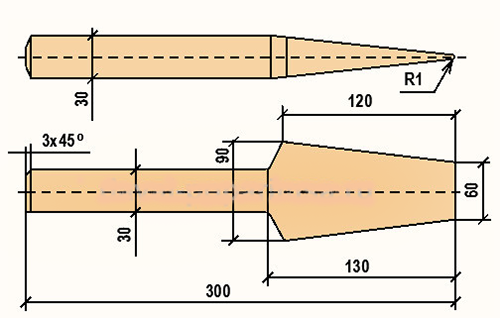

You will need a special tool for the cutter of the cut. Power blade is a straight and curve, you will also need a cynicha to drive the material in the gap. If you failed to find such a tool in the store, it can be easily made yourself. To do this, you need the usual wooden lump of solid wood. Oak, beech, hazel, ash or birch are suitable.

Draw the contours of the product and pour the draft workpiece. Sharpen the spatula with a paint. To prevent the shock part of the shock part, make a chamfer along the contour of 3-4 mm. Treat the workpiece of the rashpyl and complete the sandpaper.

There are two methods of cores:

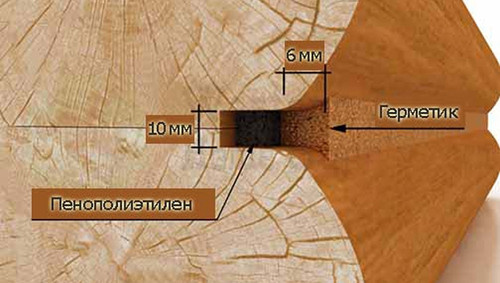

- "Stretching" - the heat insulating material is stretched along the logs, twisted it into the harness and clog over the entire length. This technique is distributed in Scandinavian countries. There, the gaps are filled with mineral wool, and then closed with a polyethylene cord, which plays the role of waterproofing. But for this, all logs must be fitted very carefully, because as a result, the most narrow seams should be obtained.

- "In the set" - the insulation laid across the logs with an allowance on both sides of 5 cm. Talking easier, the gaps are closed with large sections of the material, winding them into the ball and pushing in the emptiness with a pantry or chisel.

Useful advice: In the process of assembling a cut between the crowns, be sure to lay the insulation, for example, the jute canvas. In this case, it will be necessary for the cacopa to be just subject to a laid insulation and score it into the gap. This is a very practical and effective way that gives good thermal insulation.

Crop's technology Srub:

- The primary cape should be carried out after a complete shrinkage of the house, that is, not earlier than six months after the assembly. At this stage, the insulation is clogged into the cracks is not too tight, preferably paying attention to those sites where Vienna has not yet risen in his place. There they are converted to the insulation so as not to interfere with the final shrinkage.

- Cut the pantle from below, first finishing the very first groove around the perimeter. It is important to bypass the whole house around the perimeter, and not to work first on one wall, then on the other. This will prevent the appearance of skew.

- As it is progressed above, the jute is weaker everything is weaker, and the last grooves are simply endure without shocking on it. Remember that the jute will be "satisfying" about 5 years, during which the crowns will attach it as tight as much as possible.

- Especially carefully work in the ends and corners, since these are the most vulnerable places in a wooden srub.

- The secondary cacopate is considered the main and is carried out before or together with the house finish 1-1.5 years after the assembly. At this stage, the insulation is driven as tight as possible, after which doors, windows, wiring, plumbing and other attributes of a comfortable life are installed.

The work manually takes away the unmerced forces and time, and the last today is valued very expensive. Therefore, it is not surprising that this process decided to mechanize and make faster, simple and easy. Hanrush cutter perforator will save a lot of free time. The device must operate in a pure impact mode without rotation. You can use chisel or metal blade as a nozzle. During work, do not press the tool, otherwise the chisel will be stuck between the logs. His own shock force is quite enough.

Useful advice: Do not work in a jackhammer mode longer than 10-15 minutes. After this time, switch the perforator to rotate so that the lubricant in the cartridge is properly distributed.

It is believed that the caulking is a mechanized method gives a less qualitative result than manual, but no one has provided confirmation yet. You can compare both methods on personal experience.

Finally - a useful video about Konopatka Sruba:

CONKOP CONKEE Sealant - Modern insulation technology - http://laurex.ru.

Pantle breeding canopies - Modern insulation technology - Laurex. Ru